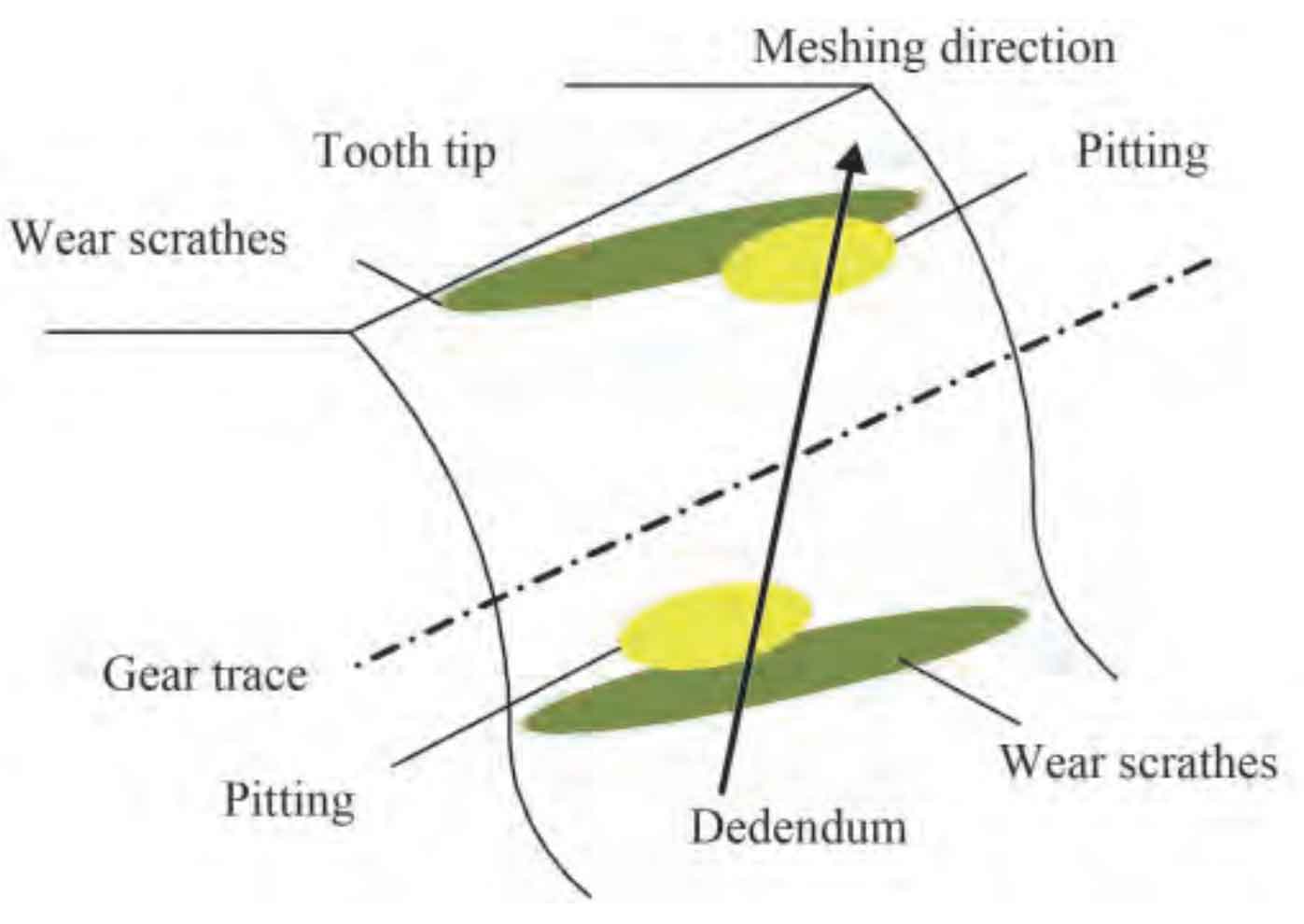

The automobile gear is in the state of continuous load operation. There are both rolling and sliding between the meshing surfaces of the automobile gear. At the same time, the tooth root is also affected by pulse and alternating bending stress. There are usually four different failure modes of Automobile Gears: ① tooth fracture; ② Macro pitting and micro pitting; ③ Wear; ④ Tooth surface gluing. As shown in the figure, the damage location model of automobile gear is shown.

Most of the failures of the above automobile gears come from the surface of the tooth surface or tooth root. Therefore, it can be seen that the surface of the gear is very important. The surface integrity of the automobile gear refers to the surface state without damage or strengthening and the performance determined by it. The surface integrity of the automobile gear includes surface residual stress, microhardness, surface roughness, microstructure, etc. for the surface coating modification of the automobile gear, factors such as thickness and bonding strength should also be considered. Both surface chemical heat treatment and shot peening deformation strengthening treatment have an impact on the surface roughness, morphological characteristics, microstructure, hardness and residual stress of the surface integrity of automobile gears. There is a close relationship between the surface integrity of automobile gears and its bending fatigue resistance and contact fatigue resistance.