The gear core of the electric rock drill is composed of 11 parts. During its operation, it is required to apply 1800-2000 times / min of impact cycles, 200 times / min of torsion cycles and 70-100mpa of impact force to the drill rod. Except for the shell, all parts of the core are made of 20 steel, carburized + quenched + tempered at low temperature. According to the manufacturer, the heat treatment is carried out according to the standard process. When the machine is equipped and put into use for less than two hours, all seven main parts of the core are damaged. The damage is shown in Fig. 9 and FIG. 10. It is mainly fracture and deformation. Typical fractures are shown in FIG. 11, all of which have primary fracture characteristics.

According to the analysis of the inspection results, the fracture of the above parts is a brittle fracture failure. The main reason is that the heating temperature of carburizing and quenching is too high and the tempering is not enough, resulting in overheating structure and quenching cracks inside, which greatly increases the brittleness of the parts. Secondly, due to improper material selection, low-carbon carburizing can not meet the strength requirements of the parts in use, such as obvious deformation of key parts. It is suggested that 40Cr steel should be used for cyanide treatment, and the problem has been solved successfully.

The failure situation of four main parts is shown. The surface layer of No.1 part arrow is peeling off, and the rod body is bent; No.2, No.3 and No.4 parts are cracked in two except the surface layer is peeling off.

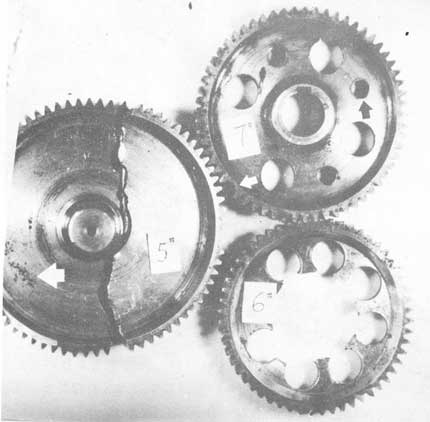

The failure of three gears is shown. No. 5 gear is broken in two. No. 6 gear shaft hole is missing, cut from the round hole. Eight holes were drilled in the center of the gear in order to reduce the weight, but seriously weaken the strength. No. 7 gear has one tooth falling, as indicated by the white arrow. Although the breaking condition is not serious, there is obvious deformation. There are three obvious out of round holes in the four holes, as indicated by the black arrow. In addition, the three gears have different degrees of peeling, as indicated by the big white arrow.

Fracture of 3, 4 and 5 parts. Part 3 is an internal gear ring broken into two sections; Part 4 has obvious quenching cracks at the sharp corners of the inner six holes, as indicated by the arrow; Part 5 also has internal defects, as indicated by the arrow. These three fractures have no fatigue characteristics, but only one fracture. The fracture is porcelain like, with quite a lot of internal points (crystallized).