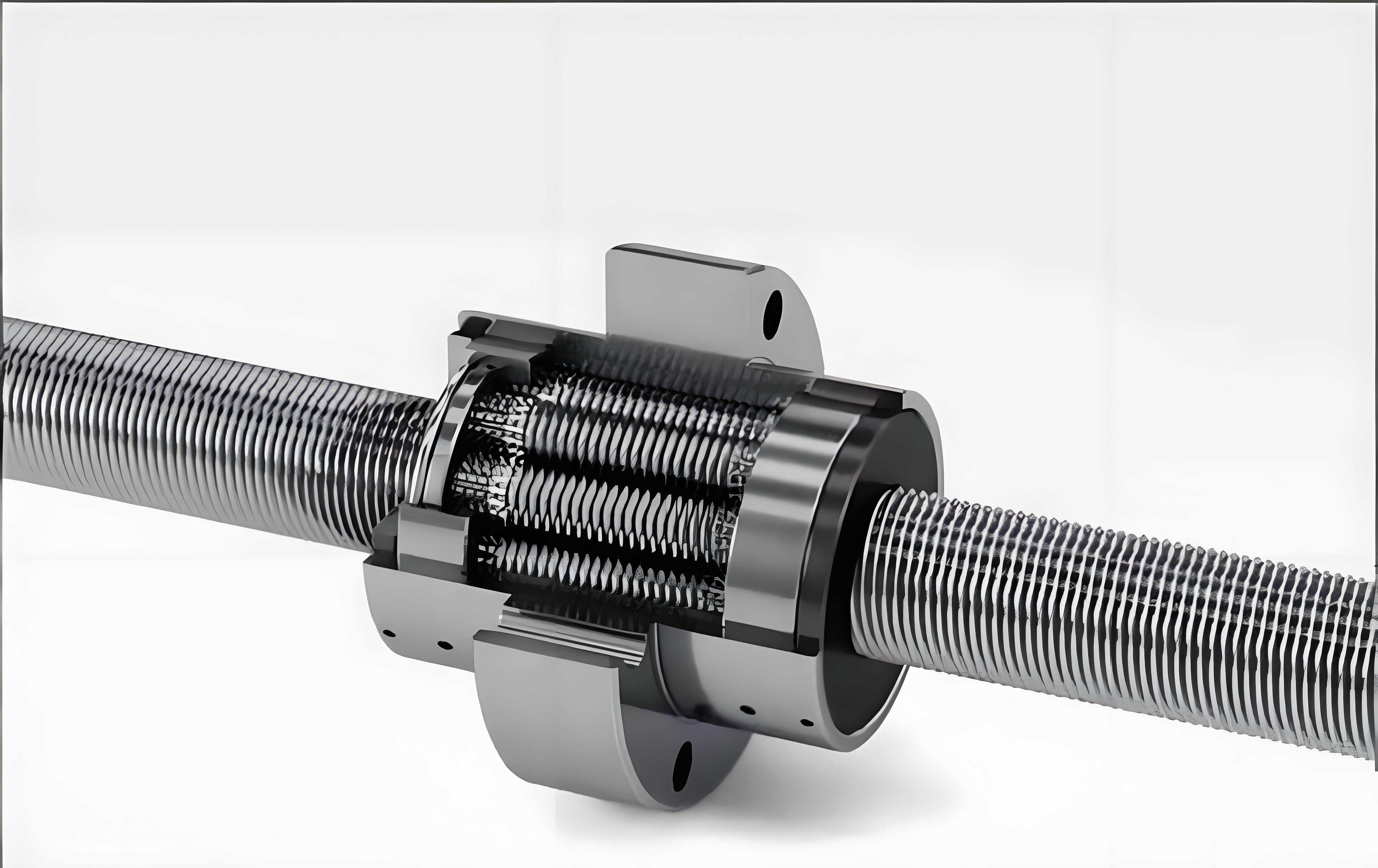

The pursuit of higher precision, greater load capacity, and improved reliability in advanced mechanical systems for aerospace, robotics, and high-performance machine tools has driven the development of sophisticated motion conversion mechanisms. Among these, the planetary roller screw assembly (PRSA) stands out for its superior performance characteristics compared to traditional ball screws. A specific derivative, the Recirculating Planetary Roller Screw Mechanism (RPRSM), offers unique advantages through its design, enabling continuous motion via a set of grooved rollers that recirculate within the nut. However, the operational integrity and longevity of such a planetary roller screw assembly are critically dependent on its ability to withstand dynamic loads, particularly random vibrations encountered in service. This work presents a comprehensive investigation into the fatigue characteristics and service life prediction of an RPRSM under random vibrational excitation, combining finite element analysis (FEA) with established fatigue life prediction theories.

The core function of a planetary roller screw assembly is to convert rotary motion into linear thrust with high efficiency and minimal backlash. In the RPRSM variant, the screw features a multi-start thread and rotates, while the nut, which contains a non-threaded section, translates linearly. The motion is transmitted through several grooved rollers that mesh with both the screw and nut threads. Unlike a standard PRSA, the rollers in an RPRSM do not have a helical lead. Instead, they orbit around the screw axis while rotating on their own axes. A critical component, the cam ring, guides these rollers through a recirculation path, allowing them to disengage, traverse the non-threaded section of the nut, and re-engage to complete a continuous circuit. This design eliminates the need for internal roller lead matching, simplifying manufacture, but introduces dynamic interactions at the re-engagement points that can be sources of vibration and stress concentration.

Predicting the fatigue life of mechanical components subjected to random vibration is a fundamental challenge in reliability engineering. The approach typically hinges on three pillars: a characterization of the material’s resistance to cyclic loading, a statistical description of the stress history, and a damage accumulation rule. The material behavior is commonly defined by the stress-life (S-N) curve, often expressed in the power-law form:

$$S^k N = C$$

where $S$ is the stress amplitude, $N$ is the number of cycles to failure, and $k$ and $C$ are material constants. For structures under random vibration, the stress response is a random process best described by its Power Spectral Density (PSD), $W(f)$. The moments of the PSD curve are crucial for life estimation:

$$m_i = \int_{-\infty}^{+\infty} f^i W(f) df$$

where $m_i$ is the $i$-th spectral moment. Key parameters derived from these moments include the expected rate of zero up-crossings, $E[0^+]$, and the expected peak frequency, $E[P]$:

$$E[0^+] = \frac{1}{2\pi}\sqrt{\frac{m_2}{m_0}}, \quad E[P] = \frac{1}{2\pi}\sqrt{\frac{m_4}{m_2}}$$

The linear cumulative damage rule postulated by Miner is widely used due to its simplicity. It states that failure occurs when the sum of the cycle ratios equals unity:

$$D = \sum_{i=1}^{n} \frac{n_i}{N_i} = 1$$

where $n_i$ is the number of cycles at a given stress level $S_i$, and $N_i$ is the life at that level from the S-N curve. The total expected damage $D$ over time $T$ under a random stress process involves integrating the damage from all possible stress amplitudes. Several analytical models have been developed to approximate this integral based on the statistical properties of the stress response. Four prominent models were employed in this study for comparison:

1. The Narrowband (NB) Method: This method assumes the stress process is narrowband, meaning its peaks are regularly spaced and each peak has a corresponding trough of similar magnitude. It assumes the amplitude distribution follows a Rayleigh distribution, leading to the fatigue damage estimate:

$$D_{NB} = \frac{E[0^+] T}{C} (2m_0)^{k/2} \Gamma(1+\frac{k}{2})$$

where $\Gamma(\cdot)$ is the Gamma function. While simple, it is known to be conservative for broadband processes.

2. The Dirlik (DK) Method: This empirical method is considered one of the most accurate for a wide range of bandwidths. It approximates the amplitude probability density function (PDF) as a combination of one exponential and two Rayleigh distributions:

$$p(s) = \frac{\frac{D_1}{Q}e^{-Z/Q} + \frac{D_2 Z}{R^2}e^{-Z^2/(2R^2)} + D_3 Z e^{-Z^2/2}}{\sqrt{m_0}}$$

where $Z = s/\sqrt{m_0}$, and $D_1, D_2, D_3, Q, R$ are parameters derived from the spectral moments $m_0, m_1, m_2, m_4$. The corresponding fatigue damage is:

$$D_{DK} = \frac{E[P] T}{C} (\sqrt{m_0})^k \left( D_1 Q^k \Gamma(1+k) + \sqrt{2}^k \Gamma(1+\frac{k}{2})(D_2 |R|^k + D_3) \right)$$

3. The Tovo-Benasciutti (TB) Method: This method estimates the rainflow damage by interpolating between the upper and lower bounds of damage intensity, weighted by a factor based on the bandwidth parameters. The damage is given by:

$$D_{TB} = \left[ w + (1-w) \alpha_2^{k-1} \right] D_{NB}$$

where $\alpha_2 = m_2 / \sqrt{m_0 m_4}$ is a bandwidth parameter, and $w$ is a weighting factor defined by the model.

4. The Zhao-Baker (ZB) Method: This approach models the amplitude PDF as a linear combination of a Weibull distribution and a Rayleigh distribution:

$$p(Z_1) = \kappa \alpha \beta Z_1^{\beta-1} e^{-\alpha Z_1^\beta} + (1-\kappa) Z_1 e^{-Z_1^2/2}$$

where $Z_1 = s/\sqrt{m_0}$. The parameters $\alpha, \beta, \kappa$ are functions of the bandwidth parameter $\alpha_2$. The fatigue damage is:

$$D_{ZB} = \frac{E[P]}{C} m_0^{k/2} \left( \kappa \alpha^{-k/\beta} \Gamma(1+\frac{k}{\beta}) + (1-\kappa) 2^{k/2} \Gamma(1+\frac{k}{2}) \right)$$

The subject of this analysis is an RPRSM with components manufactured from GCr15 bearing steel, a common choice for high-stress mechanical components. Its material properties are essential inputs for both FEA and fatigue calculations and are summarized below:

| Property | Value |

|---|---|

| Elastic Modulus | 2.19e11 Pa |

| Poisson’s Ratio | 0.3 |

| Density | 7800 kg/m³ |

| Tensile Strength | 861.3 MPa |

| Yield Strength | 518.4 MPa |

| Elongation | 27.95% |

The S-N curve constants for the high-cycle fatigue regime were derived from the material’s ultimate strength and standard approximations for hardened steel, providing the necessary $k$ and $C$ parameters for the life prediction models.

The first step in the dynamic analysis was a modal simulation to identify the inherent vibrational characteristics of the planetary roller screw assembly. A finite element model of the complete RPRSM, including screw, nut, rollers, and housing, was constructed. After applying appropriate material properties and contact definitions, a modal analysis was performed. The results revealed the first six natural frequencies and their corresponding mode shapes, which are critical for understanding potential resonance conditions. The results are consolidated in the following table:

| Mode Order | Natural Frequency (Hz) | Maximum Deformation (mm) | Dominant Mode Shape Description |

|---|---|---|---|

| 1 | 1,713.6 | 32.13 | Bending Vibration |

| 2 | 1,714.1 | 32.11 | Bending Vibration |

| 3 | 2,941.0 | 48.89 | Axial Vibration |

| 4 | 3,995.6 | 25.49 | Axial Vibration |

| 5 | 4,888.8 | 40.15 | Torsional Vibration |

| 6 | 4,894.9 | 40.11 | Torsional Vibration |

The analysis shows closely spaced pairs of modes (1&2, 5&6) due to structural symmetry. The maximum deformations occurred on the relatively slender screw and the thin-walled nut housing, indicating these as potential flexible elements within the planetary roller screw assembly.

Building upon the modal results, a harmonic response analysis was conducted to simulate the forced vibration of the RPRSM under a steady-state sinusoidal load. An axial force was applied to the nut flange, simulating an operational load, and the frequency was swept from 0 to 6 kHz. The primary output was the stress frequency response function (FRF) at critical locations, particularly the thread contact regions between the screw and the rollers. The analysis pinpointed several resonant peaks where stress amplitudes were significantly amplified. The most severe resonance was observed at approximately 3,960 Hz, closely aligning with the 4th mode (3,995.6 Hz) from the modal analysis. The stress contour plots at key frequencies (e.g., 1,680 Hz, 3,960 Hz, 6,000 Hz) consistently showed that the highest contact stresses were localized on the engaged flank of the screw threads, identifying this as the most critically stressed region. The stress at the resonance frequency was markedly higher, confirming it as a primary driver for potential fatigue damage.

The core of the fatigue life assessment involved random vibration analysis. The process required two main inputs: the stress frequency response function (FRF) obtained from the harmonic analysis and a definition of the input random vibration load in the form of a Power Spectral Density (PSD). For this study, the acceleration PSD input was derived from the harmonic acceleration response, focusing on the excitation along the axial (Z) direction. This load PSD was applied in the spectral fatigue module. The material’s S-N curve was input, and the Dirlik method was selected for the rainflow cycle counting and damage calculation due to its recognized accuracy for broadband processes. The Goodman correction was applied to account for mean stress effects.

The software computed the fatigue damage and life for every node in the model. The results were visualized as damage and life contour plots. The most severe damage, and consequently the shortest predicted fatigue life, was exclusively concentrated in the thread root and contact flanks of the screw, precisely matching the high-stress regions identified in the harmonic analysis. The minimum predicted fatigue life from the FEA-based simulation was found to be $2.96 \times 10^7$ cycles at the most critical node. The stress PSD response at this node exhibited a dominant peak at 3,960 Hz, with a magnitude of 16.6 MPa²/Hz, directly linking the resonant behavior to the largest contributor to fatigue damage. The results for several critical nodes are summarized below:

| Node ID | Minimum Predicted Fatigue Life (Cycles) | Maximum Damage Value |

|---|---|---|

| 747943 | 1.07e10 | 9.31e-11 |

| 608642 | 6.82e9 | 1.47e-10 |

| 636385 | 2.96e7 | 3.38e-8 |

| 664508 | 6.06e9 | 1.65e-10 |

| 747370 | 6.16e9 | 1.62e-10 |

To validate the FEA-based fatigue results, the four theoretical life prediction models (NB, DK, TB, ZB) were implemented independently. Using the same material S-N data and the computed stress PSD response from the critical node, the analytical fatigue damage and life were calculated according to the formulas presented earlier. The results from these theoretical models are presented in the following table for comparison with the simulation’s damage value:

| Theoretical Model | Predicted Minimum Life (Cycles) | Calculated Damage Value |

|---|---|---|

| Dirlik (DK) Model | 6.99e9 | 1.43e-10 |

| Narrowband (NB) Model | 7.46e9 | 1.34e-10 |

| Tovo-Benasciutti (TB) Model | 8.55e9 | 1.17e-10 |

| Zhao-Baker (ZB) Model | 9.35e9 | 1.07e-10 |

Comparing these analytical results with the average damage value from the FEA simulation (excluding the extreme maximum and minimum) allows for an assessment of accuracy. The Dirlik model showed the closest agreement with the FEA result, with a relative error of approximately 10.5%. The NB, TB, and ZB models showed progressively larger errors (17.9%, 35.0%, and 47.7% respectively). This outcome was expected, as the fatigue analysis software itself utilized the Dirlik algorithm. Furthermore, a probability density histogram of the simulated stress ranges was plotted against the theoretical PDFs from the four models. The histogram showed excellent agreement with the Dirlik distribution curve, providing strong visual confirmation of the consistency between the simulation methodology and the theoretical foundation.

This integrated study on the planetary roller screw assembly, specifically the RPRSM type, yields several significant conclusions regarding its dynamic behavior and fatigue life under random vibration. Firstly, the modal and harmonic analyses definitively identified a resonant frequency near 3,960 Hz as the most critical dynamic excitation condition. The stress amplification at this frequency was responsible for the largest single contribution to the computed fatigue damage, as confirmed by the prominent peak in the stress PSD response at the same frequency. This underscores the importance of avoiding operational speeds or external excitations that coincide with this resonant band in the design of systems incorporating such a planetary roller screw assembly.

Secondly, a consistent and clear correlation was established between the high-stress regions and the low-cycle-life regions. The thread engagement zone between the screw and the rollers was unanimously identified by both static-stress (harmonic response) and dynamic-damage (random vibration fatigue) analyses as the structural weak point and the most likely location for fatigue crack initiation and failure. This provides a direct and critical target for design optimization efforts aimed at improving the longevity of the planetary roller screw assembly, such as employing thread root profiling, surface treatments, or material upgrades in this specific area.

Thirdly, the comparative study of life prediction models validated the use of the Dirlik method for this application. Its close agreement with the FEA-based result, which is considered a high-fidelity virtual test, confirms its suitability for estimating the random vibration fatigue life of a complex planetary roller screw assembly with a broadband stress response. The other models, while useful, demonstrated varying degrees of conservatism or inaccuracy for this specific case.

In summary, the methodology demonstrated herein—combining detailed finite element modeling for dynamic analysis with spectral fatigue techniques and theoretical model verification—provides a robust framework for assessing the durability of a planetary roller screw assembly. The findings offer concrete guidance for designers: to mitigate vibration-induced fatigue, special attention must be paid to suppressing the resonance near 4 kHz and to enhancing the fatigue resistance of the screw thread contact surfaces. Future work could expand this analysis to include multi-axial random vibration inputs, different boundary condition configurations, and experimental validation to further refine the life prediction accuracy and the understanding of failure mechanisms in these high-performance mechanical actuators.