Within the scope of on-line elasticity, the theory of fatigue crack growth rate of spur gear is mainly Paris theory. On this basis, scholars continue to forge ahead and have made some achievements. At present, Paris theory is the most widely used and mature model to study the fatigue crack of spur gear root.

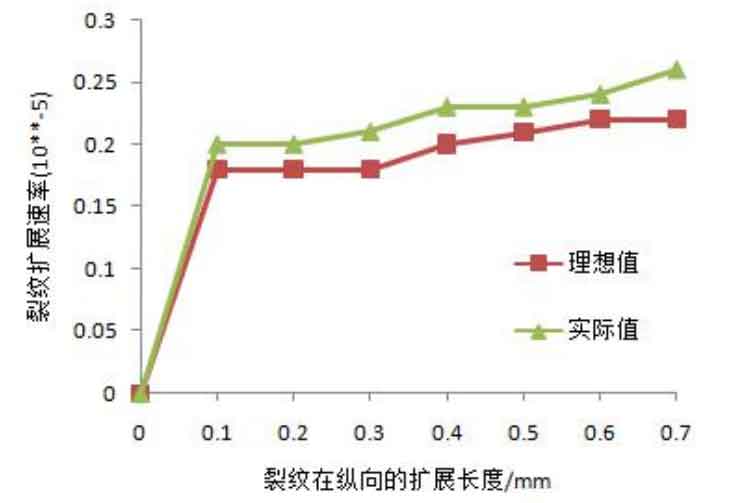

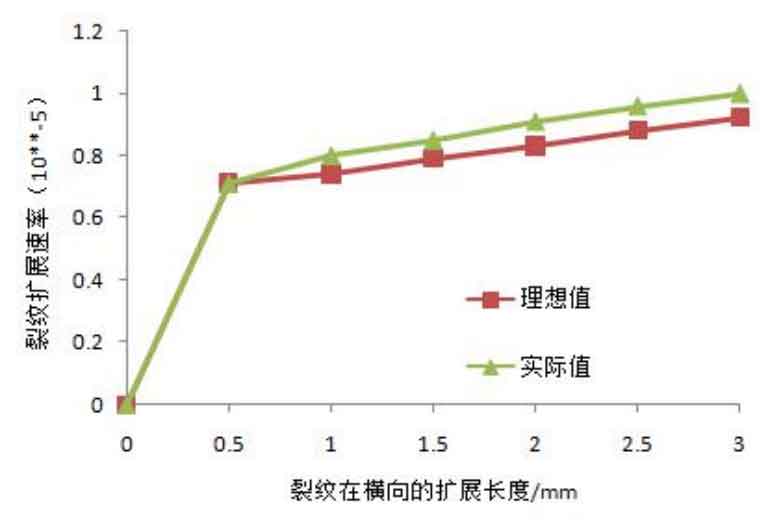

Based on Paris theory, the crack propagation rate of spur gear under ideal uniform load and actual load is simulated and analyzed by using FRANC3D software. From the data obtained by simulating the crack propagation of spur gear, it can be seen that under the same load cycle, the propagation length of spur gear crack in the tooth root and on the tooth root surface is very different, so the data obtained from life prediction are used to study the propagation rate of spur gear crack in the tooth root (longitudinal) and on the tooth root surface (transverse) respectively.

The variation curve of fatigue crack growth rate of spur gear under ideal uniform load and actual load is shown in the figure. From the variation curve of fatigue crack growth rate of spur gear given in the figure, it can be seen that under the same load, the crack growth rate of spur gear in the transverse direction (tooth root surface) is much faster than that in the longitudinal direction (tooth root interior), and after the crack growth of spur gear, the crack rate of spur gear increases with the crack growth length, Basically maintain steady growth. Comparing the crack growth rates under different loads, it can be seen that under the actual load, the crack growth rate of spur gear is faster, that is, the uneven distribution of load among points on the contact line will accelerate the crack growth rate.