The unreasonable selection of the finishing quantity will directly affect the filling condition of the tooth profile and the roughness of the tooth surface during the cold finishing of the spiral bevel gear. In addition, it also has an impact on the forming force required for the cold finishing of the tooth profile of the spiral bevel gear and the service life of the die. Therefore, how to determine the size of the finishing quantity is of great significance.

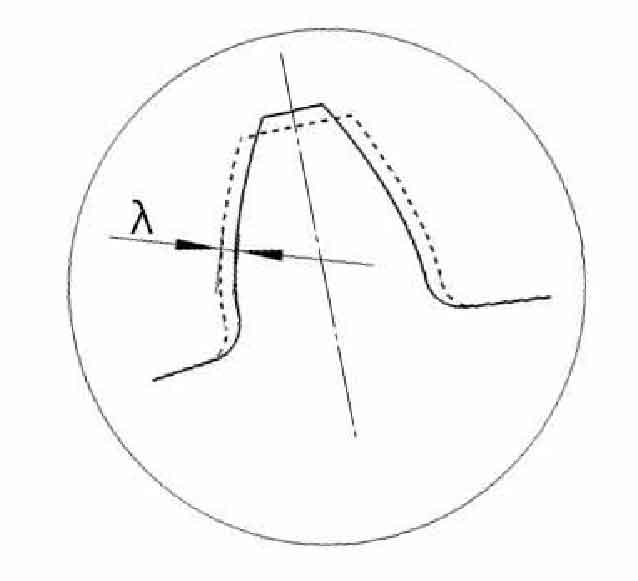

According to the structural characteristics of the tooth shape of the driven spiral bevel gear of the automobile rear axle, the equidistant hot forging tooth shape method is used to study the influence of the finishing amount of the tooth shape blank on the tooth shape. Equal distance hot forging tooth profile method of spiral bevel gear is based on the part drawing of spiral bevel gear, according to the requirements of finishing quantity during cold finishing, the tooth surface of spiral bevel gear tooth blank is evenly offset outward, combined with the principle of constant volume of metal plastic forming theory, the diameter of tooth top circle is reduced to a certain extent, so that the conical surface of spiral bevel gear tooth blank is offset inward, and the design is the structural diagram of equal distance hot forging tooth profile as shown in the figure, The solid line is the outline tooth profile after cold finishing, and the dotted line is the tooth blank formed by hot forging. The uniform outward unilateral offset of the tooth surface of the spiral bevel gear tooth blank is set as λ。

| Scheme | 1 | 2 | 3 | 4 |

| Finishing quantity λ / mm | 0.15 | 0.3 | 0.45 | 0.6 |

Based on the above forming method, by changing the finishing amount λ Four cold finishing schemes of spiral bevel gear tooth blank are formulated (as shown in the table), which are studied with the help of finite element simulation software DEFORM-3D λ Influence on the tooth profile forming of spiral bevel gear.