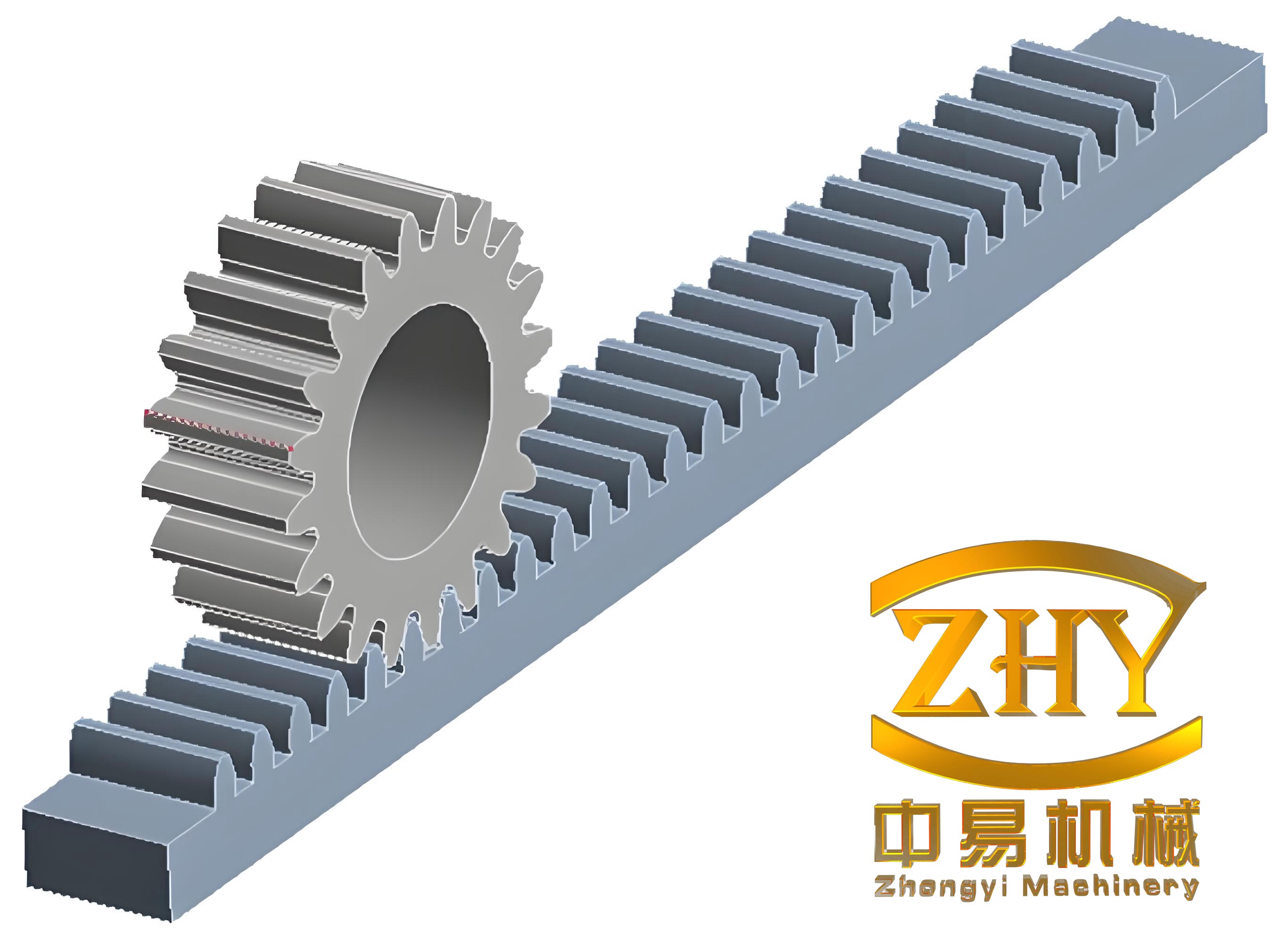

In modern petroleum and natural gas extraction, the demand for advanced drilling technologies has intensified, particularly with the shift towards deeper and more complex reservoirs. Conventional drilling rigs often face limitations in active pressure application and transport efficiency, leading to the development of top drive drilling rigs. Among the critical components of these rigs, the rack and pinion gear mechanism plays a pivotal role in load transmission and vertical motion. This mechanism must withstand heavy loads and complex stress conditions, making its strength a decisive factor for the entire drilling platform’s operational safety. In this study, I focus on analyzing the strength of the rack and pinion gear system using finite element methods to ensure reliability under extreme working conditions. The rack and pinion gear arrangement is essential for converting rotational motion into linear movement, and its failure could lead to catastrophic outcomes. Therefore, a detailed investigation into the stress and strain distributions is imperative.

The rack and pinion gear system in top drive drilling rigs operates under high torque and axial loads, which necessitates a robust design. Traditional strength calculations, based on Hertzian contact theory and bending stress formulas, may not fully capture the complex interactions in such heavy-duty applications. Finite element analysis (FEA) offers a more accurate approach by simulating real-world conditions. In this paper, I present a comprehensive finite element model of the rack and pinion gear mechanism, utilizing ANSYS software to compute stress and strain distributions. The results are compared with theoretical calculations to validate the methodology. This research aims to provide a reliable framework for designing and optimizing rack and pinion systems in similar heavy machinery, emphasizing the importance of surface strength and contact behavior.

The fundamental principles of rack and pinion gear systems involve the engagement of a gear (pinion) with a linear rack, where the pinion’s rotation drives the rack’s translation. For top drive drilling rigs, this mechanism is subjected to dynamic loads, including shock and vibration, which can exacerbate stress concentrations. The gear and rack are typically made from high-strength materials to endure these conditions. In this analysis, the pinion is constructed from 20CrMnMo steel, while the rack is made from 42CrMo steel, both selected for their excellent mechanical properties and hardness after carburizing. The key parameters for the rack and pinion gear are summarized in Table 1, which includes modulus, number of teeth, pressure angle, and other geometric details. These parameters are crucial for accurate modeling and simulation.

| Parameter | Pinion | Rack |

|---|---|---|

| Modulus, m (mm) | 20 | 20 |

| Number of Teeth, Z | 17 | – |

| Pressure Angle, α (°) | 20 | 20 |

| Addendum Coefficient, ha* | 1 | 1 |

| Dedendum Coefficient, c* | 0.25 | 0.25 |

| Width, b (mm) | 120 | 140 |

| Pitch Circle Diameter, d (mm) | 340 | – |

The material properties of the rack and pinion gear components are critical for finite element analysis, as they influence stress distributions and deformation. Table 2 outlines the elastic modulus, Poisson’s ratio, tensile strength, yield strength, and density for both materials. These values are input into the ANSYS software to ensure realistic simulations. The high tensile and yield strengths indicate the materials’ suitability for heavy-load applications, but localized stress peaks must be carefully evaluated to prevent failure.

| Property | Pinion (20CrMnMo) | Rack (42CrMo) |

|---|---|---|

| Tensile Strength (MPa) | 1180 | 1080 |

| Yield Strength (MPa) | 885 | 930 |

| Elastic Modulus (N/m²) | 2.07 × 1011 | 2.12 × 1011 |

| Poisson’s Ratio | 0.254 | 0.280 |

| Density (kg/m³) | 7870 | 7850 |

To perform the finite element analysis, I developed a three-dimensional model of the rack and pinion gear system based on the parameters in Table 1. The model accounts for the involute profile of the pinion and the straight teeth of the rack, ensuring accurate meshing conditions. The contact ratio for this system is 1.76, meaning that at certain points, two pairs of teeth share the load, which affects stress distribution. However, the maximum bending stress occurs when the load is applied at the highest point of single-tooth contact. The finite element model was created in ANSYS, with careful attention to the contact surfaces to simulate real engagement conditions. The model includes the entire assembly, with the rack fixed via bolts to the derrick and the pinion driven by a hydraulic motor.

Mesh generation is a crucial step in finite element analysis, as it impacts computational accuracy and efficiency. For this rack and pinion gear model, I employed hexahedral elements with a global size of 8 mm, resulting in 210,192 elements and 912,053 nodes. To capture the detailed stress behavior at the contact interfaces, I refined the mesh in the engagement regions, reducing the maximum element size to 0.5 mm. This approach ensures that stress concentrations are accurately represented without excessive computational cost. The meshed model exhibits uniform element distribution, which is essential for reliable results in heavy-load scenarios like those in top drive drilling rigs.

Applying constraints and loads realistically is vital for simulating the operational conditions of the rack and pinion gear system. In this setup, the rack’s bottom surface is fully constrained to represent its fixation to the derrick. The pinion is subjected to a torque of 54 kN·m and a downward hook load of 312.5 kN, derived from the rig’s maximum hook load of 2500 kN distributed evenly across eight gears. This accounts for a safety margin in the analysis. Additionally, gravitational acceleration of 9806.6 mm/s² is applied to incorporate body forces. These boundary conditions mimic the worst-case scenario during drilling operations, ensuring that the analysis covers extreme stress cases.

The finite element analysis results reveal the von-Mises stress distribution across the rack and pinion gear components. The stress cloud diagrams indicate that while the overall stress levels are manageable, localized stress concentrations occur at the tooth contact areas. Specifically, the maximum equivalent stress on the pinion is 894.4 MPa, and on the rack, it is 925.5 MPa. These peaks are observed near the tooth roots and engagement points, aligning with theoretical expectations for gear systems under load. The stress patterns highlight the importance of surface treatments to enhance durability, as the highest stresses are superficial and could lead to pitting or wear over time.

To validate the finite element results, I compared them with traditional theoretical calculations based on international standards such as GB/T 3480-1997. The contact stress and bending stress formulas are given by:

$$ \sigma_H = Z_B Z_H Z_E Z_\varepsilon Z_\beta \sqrt{\frac{2T}{b d_1^3} \cdot \frac{u \pm 1}{u} \cdot K_A K_V K_{H\alpha} K_{H\beta}} $$

$$ \sigma_F = \frac{2T}{b Z^2} \cdot Y_F Y_S Y_\varepsilon m^3 K_A K_V K_{F\alpha} K_{F\beta} $$

where the parameters are defined in Table 3. Substituting the values, the calculated contact stress σH is 1349.824 MPa, and the bending stress σF is 526.506 MPa. These results indicate that the theoretical approach predicts higher stresses than the finite element analysis, particularly for contact stress.

| Symbol | Parameter | Value | Symbol | Parameter | Value | Symbol | Parameter | Value |

|---|---|---|---|---|---|---|---|---|

| ZB | Single Pair Tooth Contact Factor | 1 | d1 | Pitch Diameter (mm) | 340 | YS | Stress Correction Factor | 1.72 |

| ZH | Zone Factor | 2.5 | u | Gear Ratio | ∞ | Yε | Helix Angle Factor for Bending | 0.628 |

| ZE | Elastic Coefficient | 191.3 | Z | Number of Teeth | 17 | KHα | Transverse Load Factor for Contact | 1 |

| Zε | Contact Ratio Factor | 0.82 | m | Modulus (mm) | 20 | KHβ | Face Load Factor for Contact | 1.24 |

| Zβ | Helix Angle Factor | 1 | KA | Application Factor | 1.1 | KFα | Transverse Load Factor for Bending | 1 |

| T | Torque (N·m) | 52,000 | KV | Dynamic Factor | 1.02 | KFβ | Face Load Factor for Bending | 1.398 |

| b | Face Width (mm) | 120 | YF | Form Factor | 2.32 |

The comparison between finite element and theoretical results shows significant discrepancies, with errors of 50.92% for contact stress and 45.85% for bending stress. This variance can be attributed to the limitations of traditional formulas, which are derived from assumptions suited for smaller modules and lighter loads. In contrast, the finite element analysis accounts for complex interactions, such as localized plasticity and contact nonlinearities, making it more representative of heavy-duty applications like the rack and pinion gear in top drive drilling rigs. The higher accuracy of FEA underscores its value in designing reliable rack and pinion systems for extreme conditions.

Further analysis of the stress distributions indicates that the contact stress on the tooth surfaces is substantially higher than the bending stress at the roots. This emphasizes the critical role of surface strength in rack and pinion gear durability. In practical terms, surface treatments such as carburizing or nitriding could be employed to enhance hardness and fatigue resistance. Additionally, the stress gradients are most pronounced in the superficial layers, suggesting that material selection and heat treatment processes should focus on improving surface properties to prevent premature failure.

The implications of this study extend beyond top drive drilling rigs to other heavy machinery utilizing rack and pinion mechanisms, such as elevators, cranes, and industrial actuators. By adopting finite element analysis as a standard design tool, engineers can optimize gear geometry, material selection, and loading conditions to minimize stress concentrations. Future work could involve dynamic analysis to account for impact loads or thermal effects, further enhancing the reliability of rack and pinion systems. Moreover, experimental validation through strain gauge measurements or fatigue testing would provide additional insights into the real-world behavior of these components.

In conclusion, this research demonstrates the effectiveness of finite element analysis in evaluating the strength of rack and pinion gear systems under heavy loads. The results confirm that the studied rack and pinion arrangement meets strength requirements, with stress levels within material limits. The significant differences between FEA and theoretical calculations highlight the need for advanced simulation techniques in designing rack and pinion gears for demanding applications. By prioritizing surface strength and leveraging finite element methods, manufacturers can ensure the safety and longevity of drilling rigs and similar equipment. This approach not only mitigates risks but also contributes to the advancement of heavy machinery engineering.