The contact stress of tooth surface and the bending stress of tooth root affect the working performance of gear, such as bearing capacity, meshing performance, transmission efficiency and so on. If the spiral bevel gear has good, safe and reliable working performance, its working stress must be calculated and analyzed.

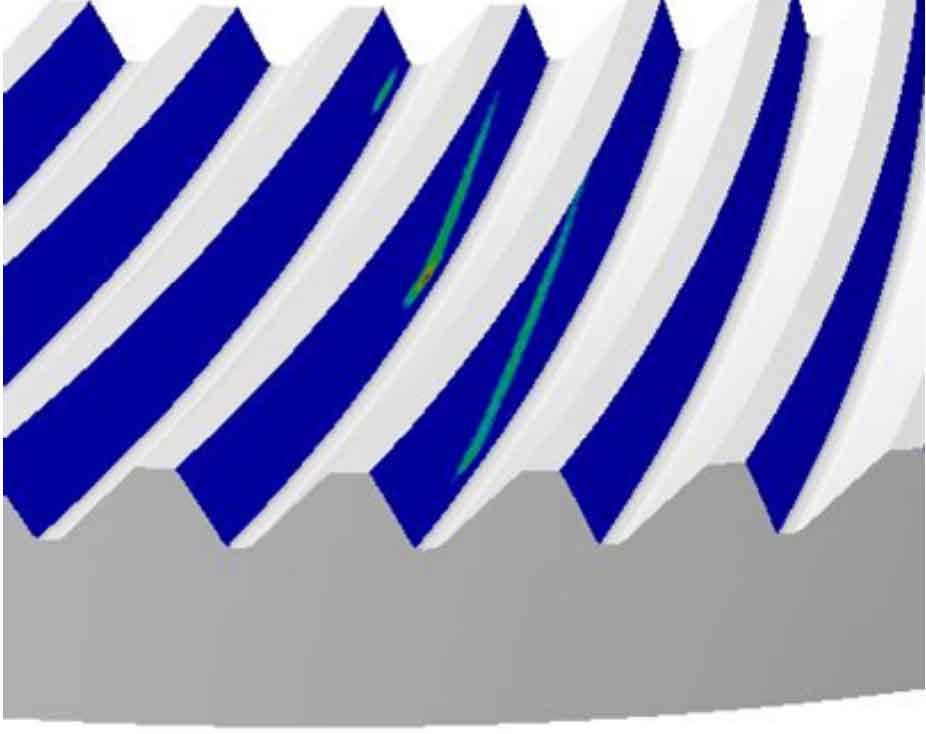

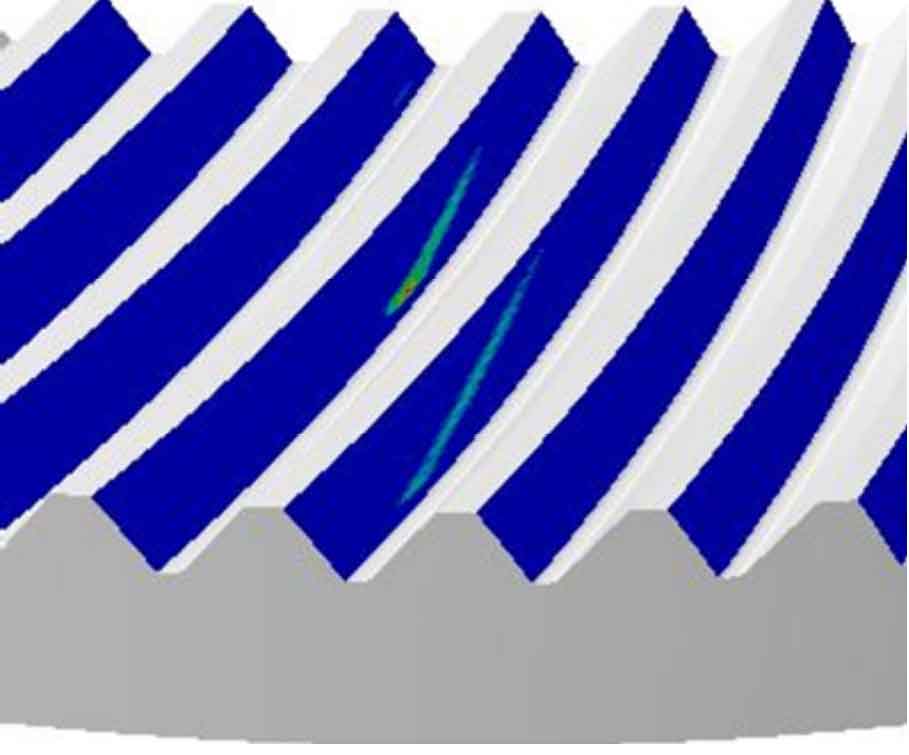

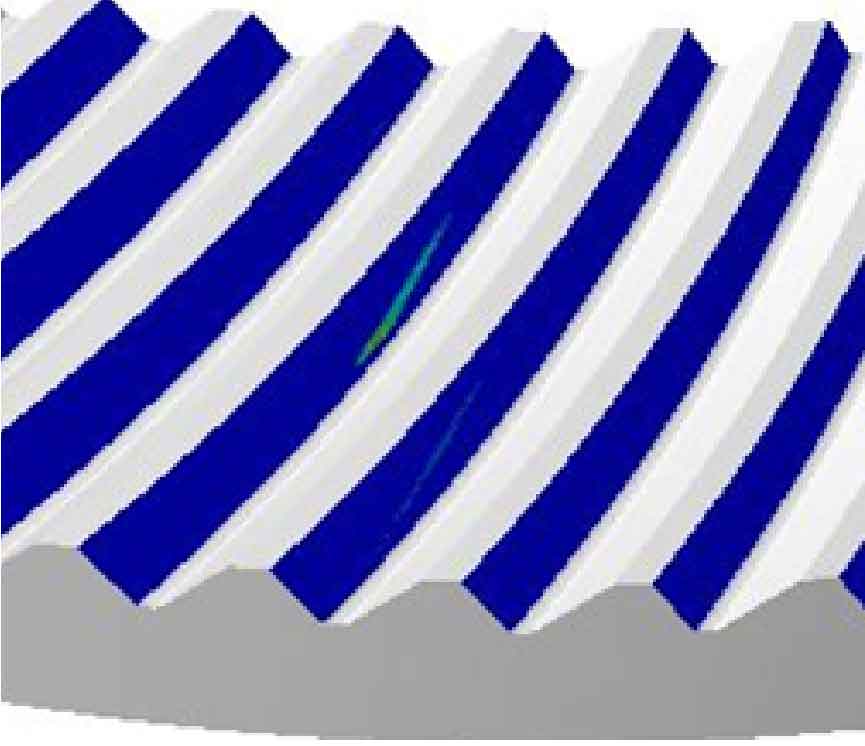

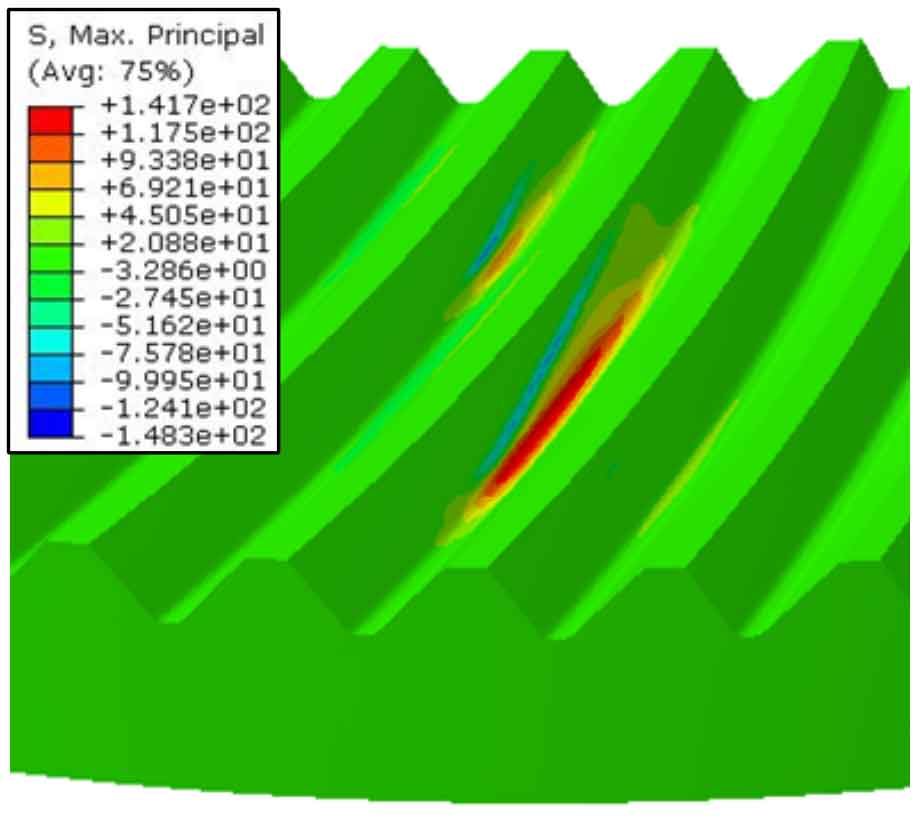

The meshing performance of spiral bevel gear can be quickly obtained by finite element analysis method. In order to analyze the influence of different loads on the tooth surface contact stress and tooth root bending stress of spiral bevel gear in the process of meshing transmission, the contact stress of spiral bevel gear can be obtained according to the ratio of contact force and contact area. The maximum tooth surface contact stress of spiral bevel gear under various working conditions. In the post-processing module, the contact stress nephogram of spiral bevel gear under different working conditions is extracted, as shown in Figure 1 ~ 3 respectively.

According to the maximum contact stress value of spiral bevel gear under different static load conditions and the contact stress cloud diagram in Figure 1 ~ 3, the maximum contact stress of gear meshing under different loads is different, and the extreme value of contact stress is also different; Under heavy load condition, the maximum contact stress of spiral bevel gear occurs in three tooth meshing. With the decrease of load, the number of meshing teeth gradually decreases to single tooth meshing; The maximum contact stress under different loads appears near the middle of the gear teeth.

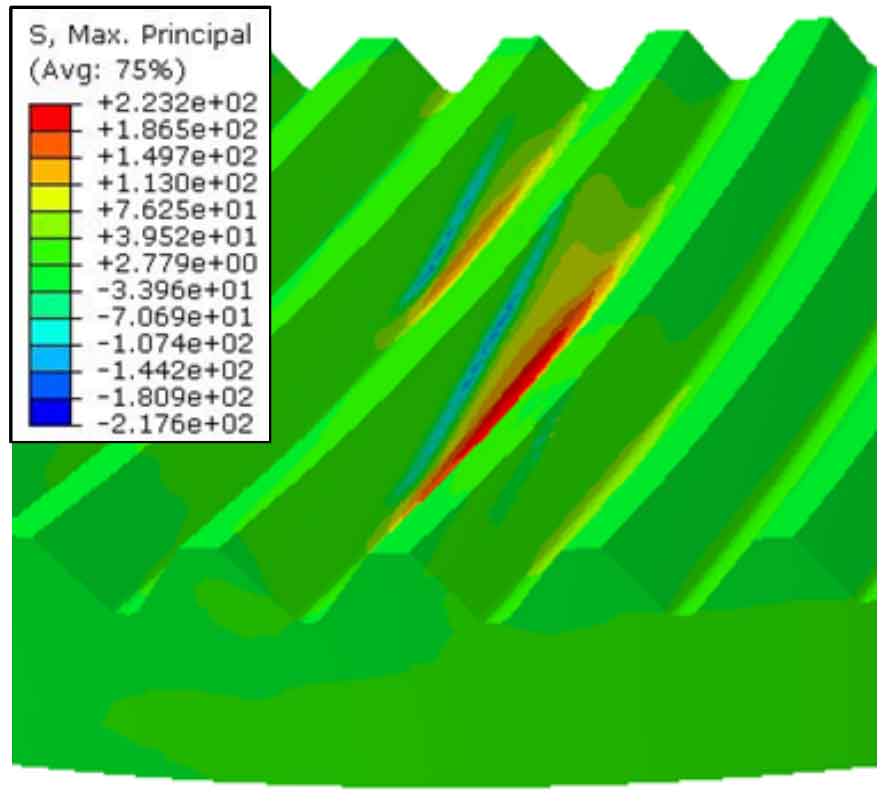

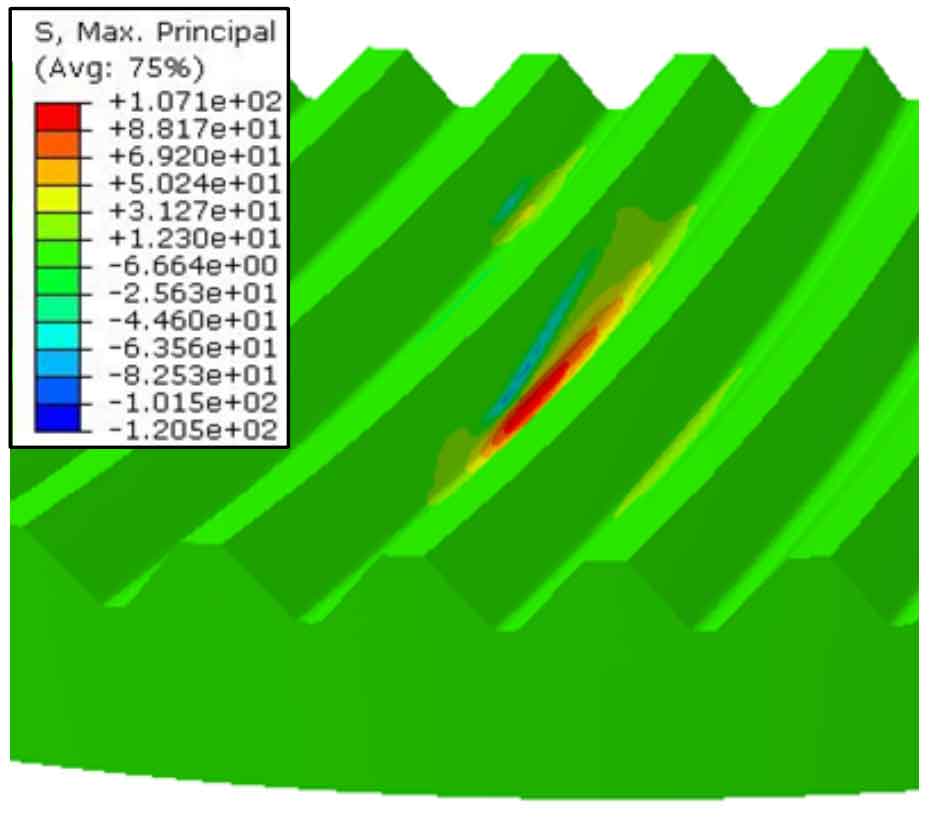

There is a direct relationship between the tooth root bending stress of spiral bevel gear and the bearing capacity of gear. When the tooth root bending stress exceeds the allowable value, it will lead to crack, fracture and other damage of gear teeth. It is of great significance to accurately obtain the variation law of tooth root bending stress of spiral bevel gear under different working conditions. The maximum value of tooth root bending stress under various working conditions is obtained from the finite element contact analysis results of spiral bevel gear. See Fig. 4-6 for the cloud diagram of tooth root bending stress under various working conditions.

According to the maximum bending stress value of spiral bevel gear under various static working conditions and the bending stress cloud diagram in Fig. 4 ~ 6, the maximum bending stress of spiral bevel gear increases with the increase of load. The location of the maximum bending stress is basically the same, and they all appear near the midpoint of the tooth width.

Based on the contact stress value of spiral bevel gear tooth surface, bending stress value of tooth root and stress cloud diagram, it can be seen that the shape of tooth surface contact area is irregular oval, and with the gradual increase of load, the contact area increases in varying degrees in both length and width directions; When the load increases, the contact stress of tooth surface and the bending stress of tooth root increase; The position of the maximum contact stress under different working conditions appears in the middle of the gear tooth, and the position of the maximum tooth root bending stress appears directly below the position of the maximum contact stress.