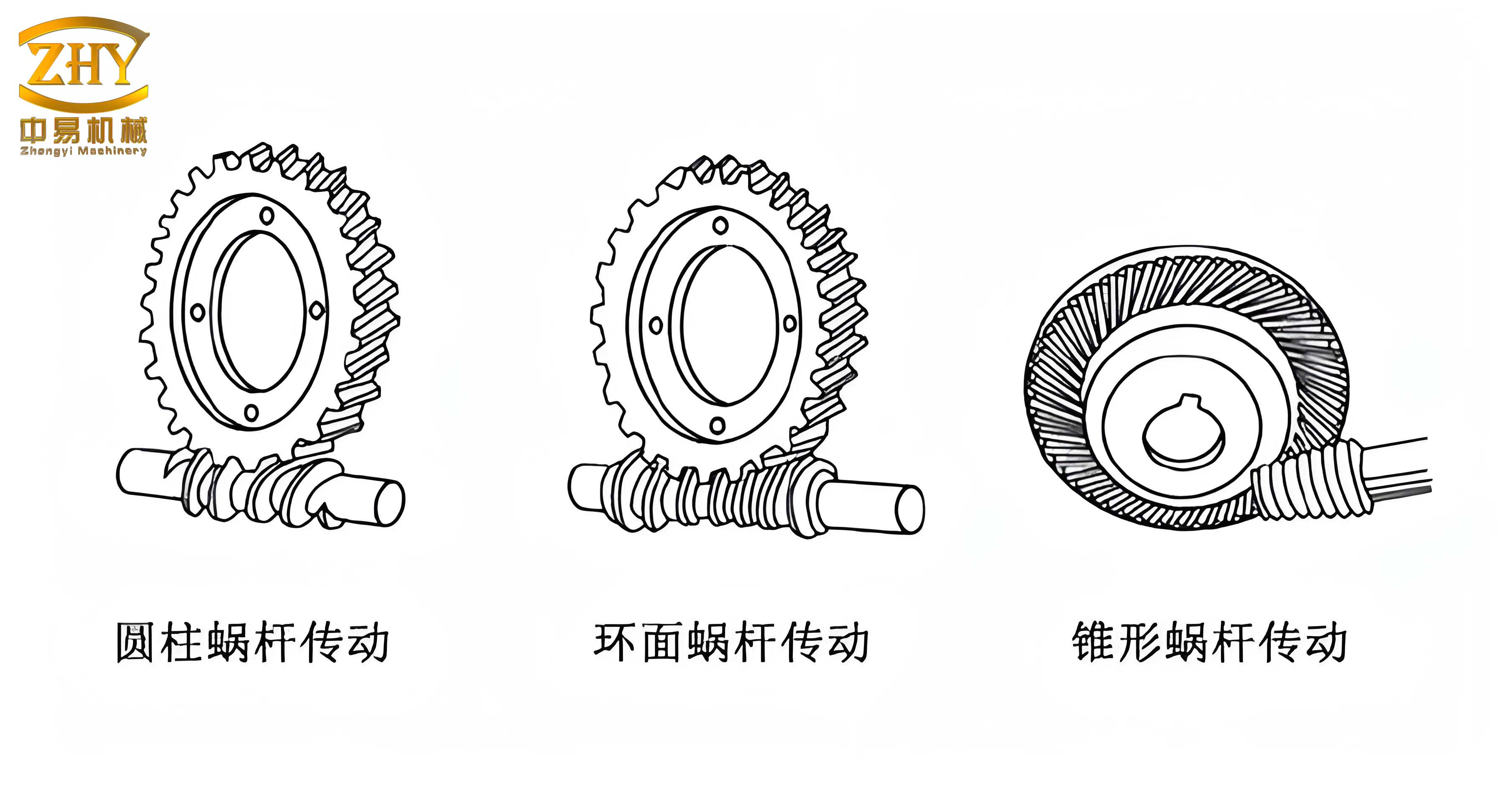

Power transmission systems involving screw gears, comprising a worm and a worm wheel, are fundamental components in machinery where high reduction ratios and torque multiplication between non-intersecting, perpendicular shafts are required. The unique sliding-rolling contact mechanism inherent to screw gear meshing, while enabling compact and high-ratio speed reduction, also introduces significant challenges related to dynamic loads, friction, and vibration excitation. These dynamic forces can induce undesirable vibrations, leading to increased noise, accelerated wear, and in severe cases, premature failure, critically impacting the overall reliability and service life of the transmission system. Therefore, a profound understanding of the dynamic characteristics, specifically the modal properties, of a complete screw gear assembly is paramount for predictive design and operational safety.

This article presents a comprehensive methodology for evaluating the transmission performance of screw gears through experimental modal analysis correlated with high-fidelity finite element method (FEM) simulations. The core objective is to extract and analyze the inherent dynamic properties—natural frequencies and mode shapes—of a screw gear reducer under free vibration conditions. This combined approach allows for the validation of numerical models against physical experiments and provides critical insights into the system’s vibrational behavior, which is essential for avoiding resonant conditions during operation and ensuring structural integrity.

Geometric Modeling and Finite Element Analysis Framework

The first step in the numerical investigation involves creating an accurate digital twin of the physical screw gear system. A detailed 3D model of a commercial WPA40-type worm gear reducer is developed. This model encompasses all primary components influencing dynamic behavior: the worm shaft, the worm wheel, supporting bearings, the housing, and end-covers. To optimize computational efficiency for modal analysis, certain simplifications are applied without sacrificing the fidelity of dynamic characteristics. Non-structural features like small fillets, chamfers, and bolt holes that have negligible impact on global stiffness and mass distribution are simplified. The primary goal is to preserve the correct connectivity, stiffness, and mass distribution of the overall assembly.

This 3D geometry is then imported into the ANSYS Workbench simulation environment. The subsequent pre-processing steps are critical for obtaining reliable results.

Material Property Definition

Accurate material modeling is essential. Each component of the screw gear drive is assigned its respective engineering material properties. The properties used in this analysis are summarized in the table below:

| Component | Material | Density, $\rho$ (kg/m³) | Young’s Modulus, $E$ (GPa) | Poisson’s Ratio, $\nu$ |

|---|---|---|---|---|

| Worm Wheel | ZCuAl10Fe3 | 7500 | 109.8 | 0.335 |

| Worm Shaft | 40# Steel | 7850 | 213.5 | 0.30 |

| Bearings | GCr15 Bearing Steel | 7830 | 219.0 | 0.30 |

| Housing & Covers | HT200 Cast Iron | 7330 | 148.0 | 0.31 |

Mesh Generation and Refinement

The assembly is discretized into finite elements. An automatic meshing algorithm is employed first, generating a predominantly tetrahedral mesh. Recognizing that the contact regions between mating components are critical stress and vibration pathways, localized mesh refinement is applied. The contact zones between the worm and worm wheel teeth, and between bearings and their seats on the shafts and housing, are specifically targeted. A finer mesh size is enforced in these regions using contact sizing controls to better capture the local stiffness effects which influence global modal frequencies. The final mesh consists of a high number of solid elements, ensuring convergence of the modal solution.

Connections and Contact Formulation

Defining how components interact is arguably the most crucial aspect of building a representative screw gear assembly model for dynamics. The contacts are defined as follows:

| Contact Pair (Body – Body) | Contact Type | Justification |

|---|---|---|

| Worm Teeth – Worm Wheel Teeth | Bonded | For free-vibration modal analysis (no external load), the meshed teeth are considered perfectly bonded to simulate the engaged state without simulating nonlinear contact. |

| Shafts – Bearings (Inner Race) | No Separation | Allows bearing inner race to slide on shaft but not separate, simulating a press fit. |

| Bearings (Outer Race) – Housing | Bonded | Simulates the outer race being press-fit into the housing bore. |

| Housing – End Covers | Bonded | Simulates bolted flange connections. |

Modal Analysis Theory and Solution Setup

The governing equation for undamped free vibration of a multi-degree-of-freedom system, like our screw gear model, is given by:

$$[M]\{\ddot{x}\} + [K]\{x\} = \{0\}$$

where $[M]$ is the mass matrix, $[K]$ is the stiffness matrix, $\{x\}$ is the displacement vector, and $\{\ddot{x}\}$ is the acceleration vector. The solution to this eigenvalue problem yields the system’s natural frequencies ($\omega_n$) and corresponding mode shapes ($\{\phi_n\}$), satisfying:

$$([K] – \omega_n^2 [M])\{\phi_n\} = \{0\}$$

In ANSYS Workbench, the Block Lanczos eigenvalue extraction method is selected for its robustness and efficiency in solving large-scale eigenvalue problems. Since lower-order modes typically dominate the dynamic response of a structure under broad-band excitation, the analysis is configured to extract the first ten natural frequencies and mode shapes within the 0-2000 Hz range. This range is most relevant for diagnosing potential resonance with common operational excitations in screw gear drives.

Experimental Modal Analysis for Validation

To validate the finite element model and obtain real-world dynamic data, an experimental modal analysis (EMA) is conducted on the physical WPA40 screw gear reducer.

Test Setup and Instrumentation

The screw gearbox is suspended by soft elastic cords to simulate free-free boundary conditions, effectively isolating it from the ground and allowing all modes to be excited. The coordinate system is defined with the X-axis parallel to the worm shaft axis, the Y-axis parallel to the worm wheel shaft axis, and the Z-axis vertical.

A grid of 18 measurement points is defined on the housing surface, capturing its geometry. A tri-axial accelerometer (sensitivity calibrated) is fixed at a single reference point (Point 1) to serve as the response transducer. A roving hammer impact test is performed: an instrumented impact hammer with a force transducer tip is used to excite each of the 18 grid points successively, while the response at the fixed accelerometer is recorded for all three translational directions (X, Y, Z).

| Equipment | Function | Key Specification |

|---|---|---|

| Tri-axial Accelerometer | Measures vibration response | High sensitivity (~100 mV/g) |

| Instrumented Impact Hammer | Provides broadband excitation | Force transducer, variable tips |

| Multi-channel Data Acquisition System | Records time-domain signals | 24-bit resolution, simultaneous sampling |

| Modal Analysis Software | Processes data, extracts modal parameters | Frequency Response Function (FRF) estimation, curve-fitting |

Data Processing and Parameter Extraction

For each impact location, a Frequency Response Function (FRF) $H(\omega)$ is estimated, relating the output acceleration at the reference point to the input force at the impact point. A set of $18 \times 3 = 54$ FRFs is generated. Using polyreference curve-fitting techniques in the modal analysis software, the global natural frequencies, damping ratios, and mode shapes are extracted from this dataset. The software identifies stable poles (frequencies and damping) consistent across multiple FRFs and synthesizes the corresponding operational deflection shapes, which for negligible damping equate to the real normal mode shapes.

Results: Correlation Between Simulation and Experiment

The primary results from both the finite element modal analysis and the experimental modal analysis are the natural frequencies and the associated mode shapes for the first ten modes. A comparison provides a direct measure of the FEM model’s accuracy.

Natural Frequency Comparison

The table below lists the first ten natural frequencies obtained from the simulation and the experiment. The percentage error is calculated as $ |f_{FEM} – f_{EXP}| / f_{EXP} \times 100\%$.

| Mode Order | FEM Frequency (Hz) | Experimental Frequency (Hz) | Error (%) |

|---|---|---|---|

| 1 | 876.4 | 868.6 | 0.89 |

| 2 | 914.6 | 902.4 | 1.33 |

| 3 | 1056.2 | 1031.0 | 2.39 |

| 4 | 1081.4 | 1071.0 | 0.96 |

| 5 | 1105.1 | 1091.0 | 1.28 |

| 6 | 1202.3 | 1190.0 | 1.02 |

| 7 | 1365.0 | 1203.0 | 11.87 |

| 8 | 1428.6 | 1376.0 | 3.68 |

| 9 | 1606.1 | 1585.0 | 1.31 |

| 10 | 1698.2 | 1625.0 | 4.31 |

The correlation for the first six modes is excellent, with errors below 2.5%. This high level of agreement validates the modeling assumptions for material properties, constraints, and mesh quality for these lower-frequency global modes. Slightly larger discrepancies are observed for modes 7, 8, and 10. These deviations can be attributed to several factors inherent in modeling a complex screw gear assembly: slight inaccuracies in representing the stiffness of bearing supports and housing walls, the simplified bonded contact at the gear mesh (which neglects local compliance), and potential variations in material properties or assembly preloads in the physical unit not captured in the model. Mode 7 shows the largest error, which may indicate that this mode is particularly sensitive to connection stiffnesses that are challenging to model perfectly.

Mode Shape Description and Comparison

The visual comparison of the animated mode shapes from the FEM and the experimental operational deflection shapes shows strong qualitative agreement for the dominant lower-order modes. The following descriptions characterize the dynamic deformation observed:

- Modes 1 & 2: These are typically global bending modes of the housing, often coupled with rocking of the entire assembly. The worm and wheel shafts participate in this motion, with the shaft ends exhibiting noticeable displacement due to their cantilevered nature beyond the bearings.

- Modes 3-6: These involve more complex combinations of housing panel flexure (side walls, top cover) and torsional/bending deformation of the shafts. The interaction between the housing flexibility and the dynamics of the rotating components becomes evident.

- Modes 7-10: These are higher-order local modes, featuring complex flexural patterns of the housing walls and covers. The deformation of the screw gear mesh region itself may become more pronounced in these higher-frequency modes.

The consistency in mode shape sequence and deformation pattern between simulation and experiment further confirms that the finite element model accurately captures the essential dynamic characteristics of the screw gear system.

Implications for Transmission Performance and Reliability

The extracted modal parameters are not merely academic results; they have direct and critical implications for the operational performance and reliability of the screw gear drive. Resonance occurs when an excitation frequency coincides with or approaches a system natural frequency, leading to amplified vibration levels, elevated dynamic stresses, accelerated wear (especially at the delicate screw gear interface), and increased noise.

For a screw gear reducer operating at a nominal input speed of 1500 RPM (25 Hz), the primary rotational excitation frequencies are related to the shaft speeds and their harmonics, as well as the tooth meshing frequency ($f_{mesh} = N_{worm} \times f_{shaft}$, where $N_{worm}$ is the number of worm threads). For a typical multi-start worm, the meshing frequency can be several hundred Hz. The modal analysis reveals that the system’s first natural frequency is above 850 Hz. This indicates a well-designed separation between the primary operational excitations and the fundamental global mode, which is favorable.

However, the analysis also provides a precise map of “forbidden” frequency zones. For instance, if the screw gear drive were to be used in a variable-speed application or be subjected to significant harmonic excitations from connected equipment (e.g., motor irregularities, load pulsations), knowledge of the precise natural frequencies (e.g., ~870 Hz, ~900 Hz, ~1030 Hz) allows designers to avoid operating conditions that would excite these modes. Furthermore, the mode shapes identify the most flexible components (e.g., specific housing panels, shaft ends) in each frequency band. This information is invaluable for targeted design improvements, such as adding strategic ribs to the housing or optimizing bearing span to stiffen a shaft, thereby shifting a problematic natural frequency away from an excitation source and enhancing the dynamic robustness of the entire screw gear transmission system.

A simplified analytical check for the fundamental bending frequency of a shaft within the screw gear assembly can be approximated using the formula for a simply supported beam with a central mass (representing the gear):

$$ f_n = \frac{1}{2\pi} \sqrt{\frac{k_{eq}}{m_{eq}}} $$

where $k_{eq}$ is an equivalent stiffness and $m_{eq}$ is an equivalent mass. While this is a gross simplification, it underscores the relationship that designers can influence: increasing stiffness or reducing mass raises the natural frequency.

Conclusion

This integrated study demonstrates a robust framework for the dynamic performance evaluation of screw gear transmission systems. By synergizing detailed finite element modeling with rigorous experimental modal testing, a high-fidelity understanding of the system’s vibrational characteristics is achieved. The close correlation between simulated and experimental natural frequencies and mode shapes validates the modeling approach, providing confidence in using the FEM for predictive design and virtual prototyping. The core outcome is the acquisition of precise modal parameters—the natural frequencies and their corresponding deformation patterns. This data forms the essential foundation for conducting reliable forced-response analyses, predicting dynamic stresses, and most importantly, performing effective resonance avoidance in the design phase. For critical applications relying on screw gear drives, such a proactive modal analysis is not merely beneficial but indispensable for ensuring long-term operational reliability, minimal maintenance, and predictable service life, ultimately safeguarding the performance of the larger mechanical system in which the screw gear is integrated.