In the process of mechanical thermal coupling analysis, it is necessary to change from thermal analysis of temperature field simulation to stress analysis. Keep the size and number of elements unchanged, convert the element type solid 70 of thermal analysis to the element type solid 45 of structural analysis, and then set the material properties of 30crmnti. The elastic modulus of 30crmnti is e = 2.05 × 1011 PA, Poisson’s ratio v = 0.25, coefficient of thermal expansion α= one point zero seven × 10-05 m2/s。 The yield strength of the material meets the Mises yield criterion and shows linear strengthening after yield.

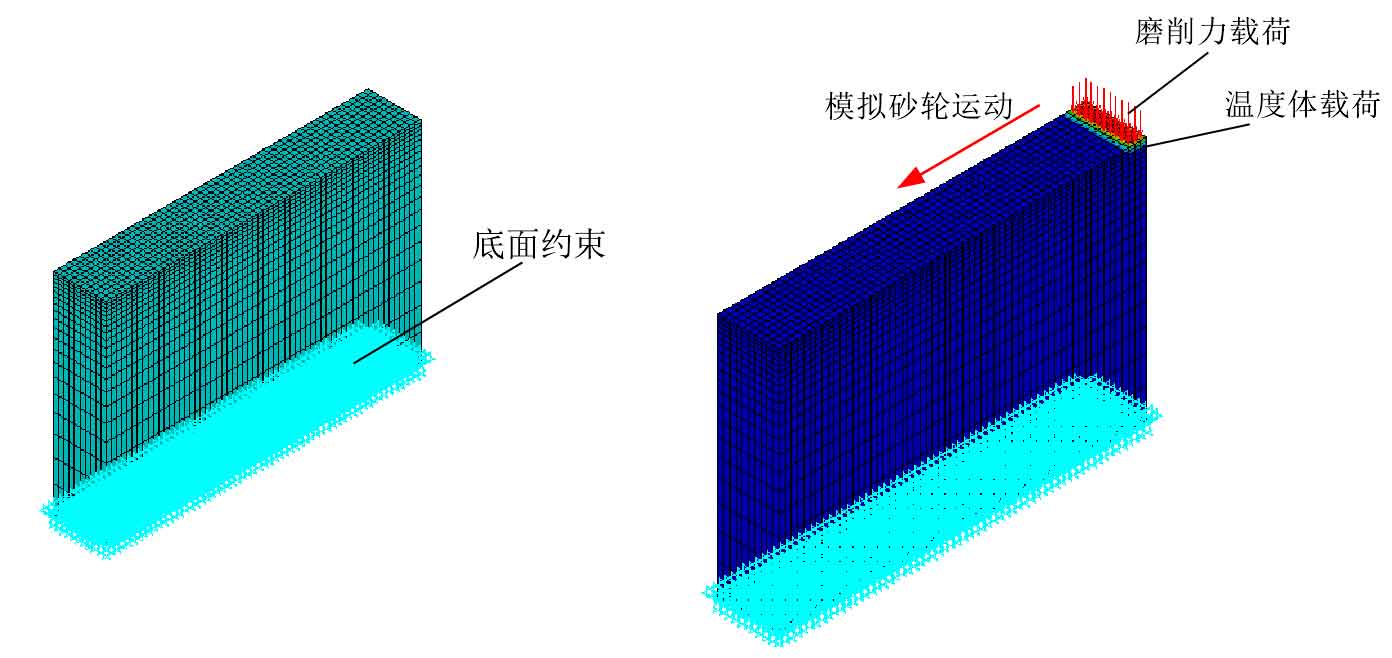

During the grinding process of bevel gear steel, the workpiece is fixed on the workbench, so the degree of freedom constraints in three displacement directions of X, y and Z are imposed on all nodes on the bottom of the workpiece in the simulation analysis. Then, the tangential force and normal grinding force in the grinding process are calculated through the empirical formula of the grinding force of bevel gear steel. The width of the force load in the grinding process of bevel gear steel is equal to the contact width between the grinding wheel and the workpiece. Like the heating flow density, the grinding force of bevel gear steel is transformed into uniform pressure and applied to the upper surface of the workpiece. Then, the cycle is set by ADPL command to move the force load on the workpiece, and the loading process of bevel gear steel grinding force is simulated, The specific process is shown in the figure.