In recent years, the demand for efficient and reliable damping systems in structural engineering has grown significantly, particularly for mitigating vibrations induced by wind and seismic events. Traditional viscous dampers, while effective, often suffer from issues such as fluid leakage, mechanical wear, and temperature sensitivity. As an alternative, eddy current damping technology has emerged due to its non-contact nature, absence of mechanical wear, and ease of parameter adjustment. This study introduces a novel Rack and Pinion Gear Based Eddy Current Damping Wall (ECD-RGW), which leverages the speed amplification effect of rack and pinion mechanisms to enhance damping performance. We conduct a comprehensive finite element analysis to investigate the mechanical behavior of ECD-RGW, focusing on key design parameters and their impact on damping characteristics. The results demonstrate that ECD-RGW offers superior damping performance and feasibility for structural vibration control, with potential applications in high-rise buildings and bridges.

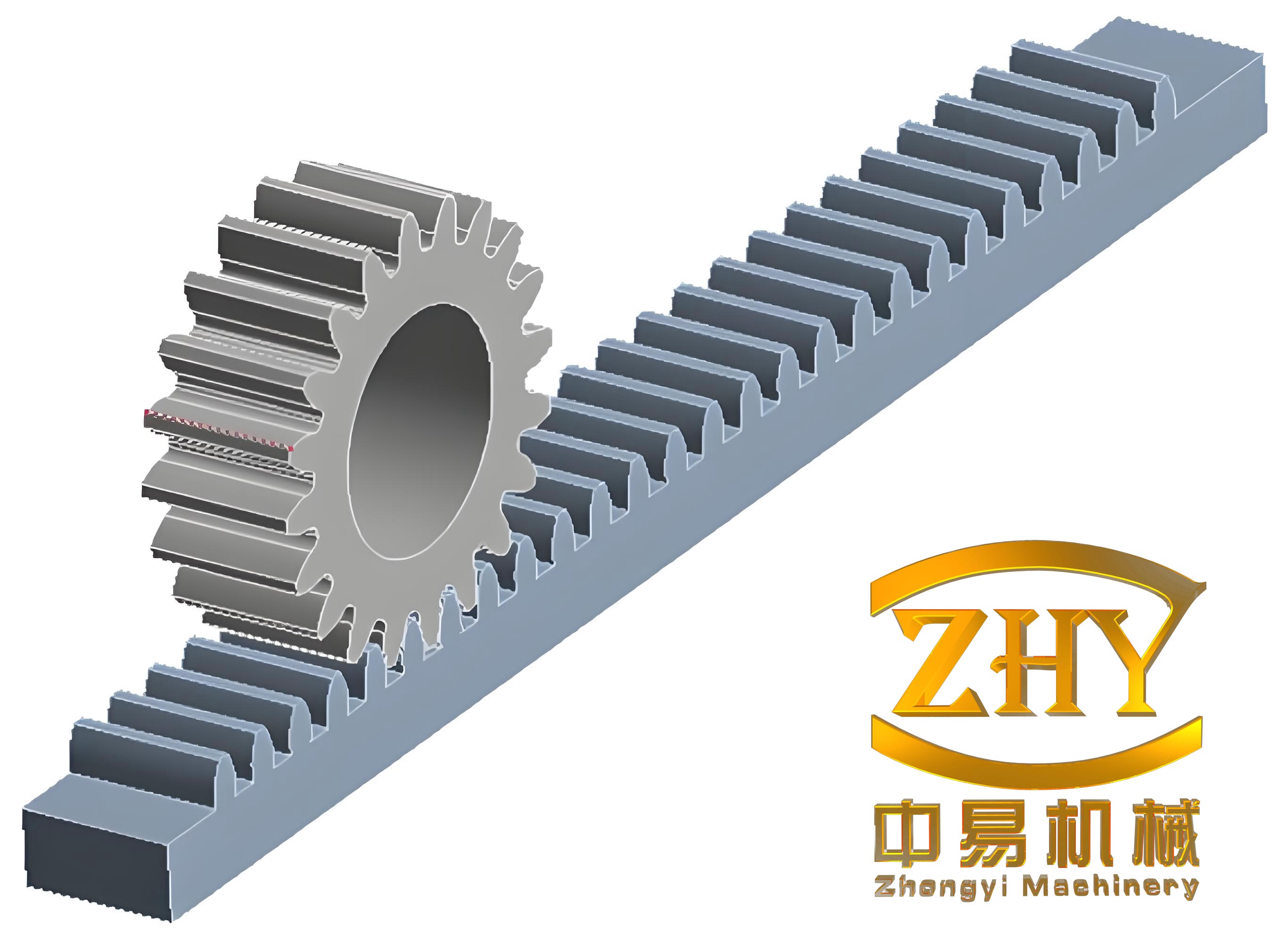

The ECD-RGW consists of two main components: a speed amplification mechanism using rack and pinion gears and an eddy current damping unit. The rack and pinion system converts linear motion into rotational motion, amplifying the velocity input to the conductor plate. Specifically, the rack engages with a primary pinion gear, which is connected to a secondary gear via a shaft, and this secondary gear drives a tertiary gear attached to the conductor plate. This multi-stage gear arrangement ensures efficient energy transmission. The eddy current unit includes permanent magnets, a conductive plate, and back iron, which work together to generate damping forces through electromagnetic induction. When relative motion occurs between structural floors, the rack moves linearly, and the rack and pinion gears amplify this motion, causing the conductor plate to rotate. The resulting eddy currents dissipate energy as heat, providing effective vibration control.

The mechanical performance of ECD-RGW is derived from the relationship between the damping force and velocity. Let the relative velocity between floors be denoted as \( \dot{u} \), which corresponds to the linear velocity of the rack. For a two-stage gear system, the angular velocity of the conductor plate \( \dot{\theta} \) is given by:

$$ \dot{\theta} = \frac{r_2}{r_1 r_3} \dot{u} $$

where \( r_1 \), \( r_2 \), and \( r_3 \) are the radii of the primary, secondary, and tertiary gears, respectively. The damping force \( F_d \) at the rack is related to the eddy current torque \( T_e \) on the conductor plate through power conservation:

$$ F_d \dot{u} = T_e \dot{\theta} $$

Substituting the expression for \( \dot{\theta} \), we obtain:

$$ F_d = T_e \frac{r_2}{r_1 r_3} $$

The equivalent damping coefficient \( c_e \) is defined as:

$$ F_d = c_e \dot{u} $$

Thus, combining the equations yields:

$$ c_e = \frac{T_e}{\dot{\theta}} \left( \frac{r_2}{r_1 r_3} \right)^2 $$

This formulation highlights the role of the rack and pinion gear system in amplifying the damping effect, making ECD-RGW a promising solution for structural applications.

To evaluate the performance of ECD-RGW, we developed a three-dimensional finite element model using COMSOL Multiphysics, a multi-physics simulation software. The model includes the eddy current damping unit and an external spherical air domain to account for magnetic field interactions. Key components such as permanent magnets, conductive plate, back iron, and air gaps are meshed with high resolution to ensure accuracy, while less critical regions use coarser grids. The standard configuration involves N52 neodymium magnets with a residual flux density of 1.43 T, a copper conductive plate with conductivity \( \sigma = 58 \, \text{MS/m} \), and a gear amplification ratio of 14.5. The simulation computes the eddy current torque \( T_e \) as a function of angular velocity \( \dot{\theta} \), which is then converted to damping force \( F_d \) using the rack and pinion relationships.

The finite element results for the standard case show that the damping force initially increases linearly with velocity, peaks at a critical velocity \( \dot{u}_{cr} = 0.652 \, \text{m/s} \) with a maximum force \( F_{d,\text{max}} = 240.49 \, \text{kN} \), and then decreases nonlinearly due to the opposing magnetic field from eddy currents. The equivalent damping coefficient decreases monotonically with velocity, indicating velocity-dependent behavior. This nonlinear characteristic is crucial for designing ECD-RGW for specific structural applications, as it affects energy dissipation efficiency across different excitation levels.

We conducted a parametric analysis to investigate the influence of key design variables on ECD-RGW performance. The parameters include the number of permanent magnets, air gap length, conductive plate back iron thickness, conductive plate material, and conductive plate thickness. Each parameter was varied while keeping others constant, and the effects on damping force and equivalent damping coefficient were analyzed.

First, the number of permanent magnets \( n \) was varied from 4 to 10 pairs. The results indicate that both damping force and initial equivalent damping coefficient increase with \( n \), but nonlinearly. For instance, the maximum damping force per magnet pair \( F_{d,\text{max}}/n \) increases slightly with \( n \), suggesting improved magnetic flux utilization. This is attributed to reduced magnetic leakage and shorter flux paths with more magnets. However, optimal magnet count depends on other factors like magnet size and air gap, requiring further optimization for specific designs.

| Number of Magnets, \( n \) | Max Damping Force, \( F_{d,\text{max}} \) (kN) | Initial Damping Coefficient, \( c_0 \) (kN·s/m) | \( F_{d,\text{max}}/n \) (kN) | \( c_0/n \) (kN·s/m) |

|---|---|---|---|---|

| 4 | 89.11 | 239.56 | 22.28 | 59.89 |

| 6 | 134.46 | 366.72 | 22.41 | 61.12 |

| 8 | 184.69 | 520.46 | 23.09 | 65.06 |

| 10 | 240.49 | 707.31 | 24.05 | 70.73 |

Second, the air gap length \( T_d \) was analyzed for values from 1 mm to 8 mm. Smaller air gaps result in higher damping forces and equivalent damping coefficients due to increased magnetic flux density in the conductive plate. The critical velocity \( \dot{u}_{cr} \) remains relatively unchanged, as it is primarily influenced by conductive plate properties. This emphasizes the importance of minimizing air gaps within practical limits to enhance performance, though manufacturing constraints must be considered.

| Air Gap Length, \( T_d \) (mm) | Max Damping Force, \( F_{d,\text{max}} \) (kN) | Critical Velocity, \( \dot{u}_{cr} \) (m/s) | Initial Damping Coefficient, \( c_0 \) (kN·s/m) |

|---|---|---|---|

| 1 | 240.49 | 0.652 | 707.31 |

| 2 | 180.25 | 0.650 | 530.12 |

| 4 | 110.18 | 0.648 | 324.05 |

| 6 | 75.42 | 0.645 | 221.82 |

| 8 | 55.31 | 0.643 | 162.68 |

Third, the thickness of the conductive plate back iron \( T_b \) was varied from 0 mm (no back iron) to 165 mm. The presence of back iron significantly boosts damping performance by forming closed magnetic circuits and reducing flux leakage. For example, at low velocities, the equivalent damping coefficient with back iron is over four times higher than without. However, increasing thickness beyond 1 mm shows diminishing returns, as the material reaches magnetic saturation. This suggests that thin back iron layers can provide substantial benefits without excessive material use.

| Back Iron Thickness, \( T_b \) (mm) | Max Damping Force, \( F_{d,\text{max}} \) (kN) | Critical Velocity, \( \dot{u}_{cr} \) (m/s) | Initial Damping Coefficient, \( c_0 \) (kN·s/m) |

|---|---|---|---|

| 0 | 60.15 | 1.452 | 165.41 |

| 1 | 235.88 | 0.655 | 693.76 |

| 4 | 238.95 | 0.653 | 702.79 |

| 8 | 239.72 | 0.652 | 705.06 |

| 16 | 240.49 | 0.652 | 707.31 |

| 165 | 242.10 | 0.651 | 712.06 |

Fourth, the conductive plate material was compared for copper (\( \sigma = 58.0 \, \text{MS/m} \)), aluminum (\( \sigma = 37.0 \, \text{MS/m} \)), and zinc (\( \sigma = 16.0 \, \text{MS/m} \)). Higher conductivity materials like copper yield lower critical velocities and higher damping forces at low speeds, but zinc exhibits a higher peak damping force at a larger critical velocity. This is because stronger eddy currents in copper create opposing fields that saturate earlier. The choice of material should align with the expected velocity range of application to optimize energy dissipation.

| Material | Conductivity, \( \sigma \) (MS/m) | Max Damping Force, \( F_{d,\text{max}} \) (kN) | Critical Velocity, \( \dot{u}_{cr} \) (m/s) | Initial Damping Coefficient, \( c_0 \) (kN·s/m) |

|---|---|---|---|---|

| Copper | 58.0 | 240.50 | 0.652 | 707.31 |

| Aluminum | 37.0 | 251.88 | 1.087 | 740.82 |

| Zinc | 16.0 | 277.53 | 2.391 | 816.26 |

Fifth, the conductive plate thickness \( T_c \) was varied from 1 mm to 8 mm. Thicker plates increase damping forces and equivalent damping coefficients at low velocities but reduce the critical velocity and peak damping force. This is due to broader eddy current distribution, which enhances low-speed performance but accelerates magnetic saturation. Designers should select thickness based on the target operating velocity range to balance initial damping and peak capacity.

| Plate Thickness, \( T_c \) (mm) | Max Damping Force, \( F_{d,\text{max}} \) (kN) | Critical Velocity, \( \dot{u}_{cr} \) (m/s) | Initial Damping Coefficient, \( c_0 \) (kN·s/m) |

|---|---|---|---|

| 1 | 275.18 | 1.245 | 809.35 |

| 2 | 240.49 | 0.652 | 707.31 |

| 4 | 195.22 | 0.435 | 574.18 |

| 6 | 165.41 | 0.326 | 486.50 |

| 8 | 145.08 | 0.261 | 426.71 |

To assess the vibration control effectiveness of ECD-RGW, we performed time history analysis on a single-degree-of-freedom (SDOF) system subjected to the El-Centro earthquake record. The system has a mass \( m = 2.07 \times 10^8 \, \text{kg} \), natural frequency \( f = 0.2219 \, \text{Hz} \), and damping ratio \( \xi = 0.02 \). The equation of motion is:

$$ m\ddot{u} + c\dot{u} + ku + F_d(\dot{u}) = -m\ddot{u}_g $$

where \( \ddot{u}_g \) is the ground acceleration, and \( F_d(\dot{u}) \) is the damping force from ECD-RGW. For comparison, we used a fluid viscous damper (FVD) with a Maxwell model:

$$ F_d(\dot{u}) = c \dot{u}^\alpha $$

where \( \alpha \) is the damping exponent. The ECD-RGW damping force is modeled using Wouterse’s nonlinear equation:

$$ F_d(\dot{u}) = \frac{F_{d,\text{max}}}{\frac{\dot{u}}{\dot{u}_{cr}} + \frac{\dot{u}_{cr}}{\dot{u}}} $$

The FVD was calibrated to match ECD-RGW’s damping force at the critical velocity. Results show that ECD-RGW reduces the displacement peak by 39.3% and root mean square (RMS) by 30.4%, comparable to FVD with \( \alpha = 0.6 \). This confirms that ECD-RGW can effectively replace traditional dampers in seismic applications, offering similar performance with additional benefits like no fluid dependency and adjustable parameters.

| Damper Type | Peak Displacement (m) | Reduction, \( \rho_1 \) (%) | RMS Displacement (m) | Reduction, \( \rho_2 \) (%) |

|---|---|---|---|---|

| No Damper | 0.3099 | 0 | 0.1502 | 0 |

| ECD-RGW | 0.1882 | 39.3 | 0.0560 | 30.4 |

| FVD (\( \alpha = 0.2 \)) | 0.1797 | 42.0 | 0.0359 | 36.9 |

| FVD (\( \alpha = 0.4 \)) | 0.1884 | 39.2 | 0.0441 | 34.2 |

| FVD (\( \alpha = 0.6 \)) | 0.1958 | 36.8 | 0.0540 | 31.0 |

| FVD (\( \alpha = 0.8 \)) | 0.2015 | 35.0 | 0.0646 | 27.6 |

| FVD (\( \alpha = 1.0 \)) | 0.2059 | 33.6 | 0.0746 | 24.4 |

In conclusion, the rack and pinion gear based eddy current damping wall (ECD-RGW) represents a significant advancement in structural damping technology. Through finite element analysis, we demonstrated that ECD-RGW exhibits robust damping performance, characterized by nonlinear force-velocity behavior. Key parameters such as the number of permanent magnets, air gap length, back iron presence, conductive plate material, and thickness critically influence the damping characteristics. The rack and pinion mechanism effectively amplifies input velocities, enhancing energy dissipation. Comparative studies with fluid viscous dampers show that ECD-RGW achieves comparable vibration reduction, making it a viable alternative for seismic and wind applications. Future work should focus on experimental validation, optimization of gear ratios, and integration into full-scale structures to further exploit the benefits of this innovative system.