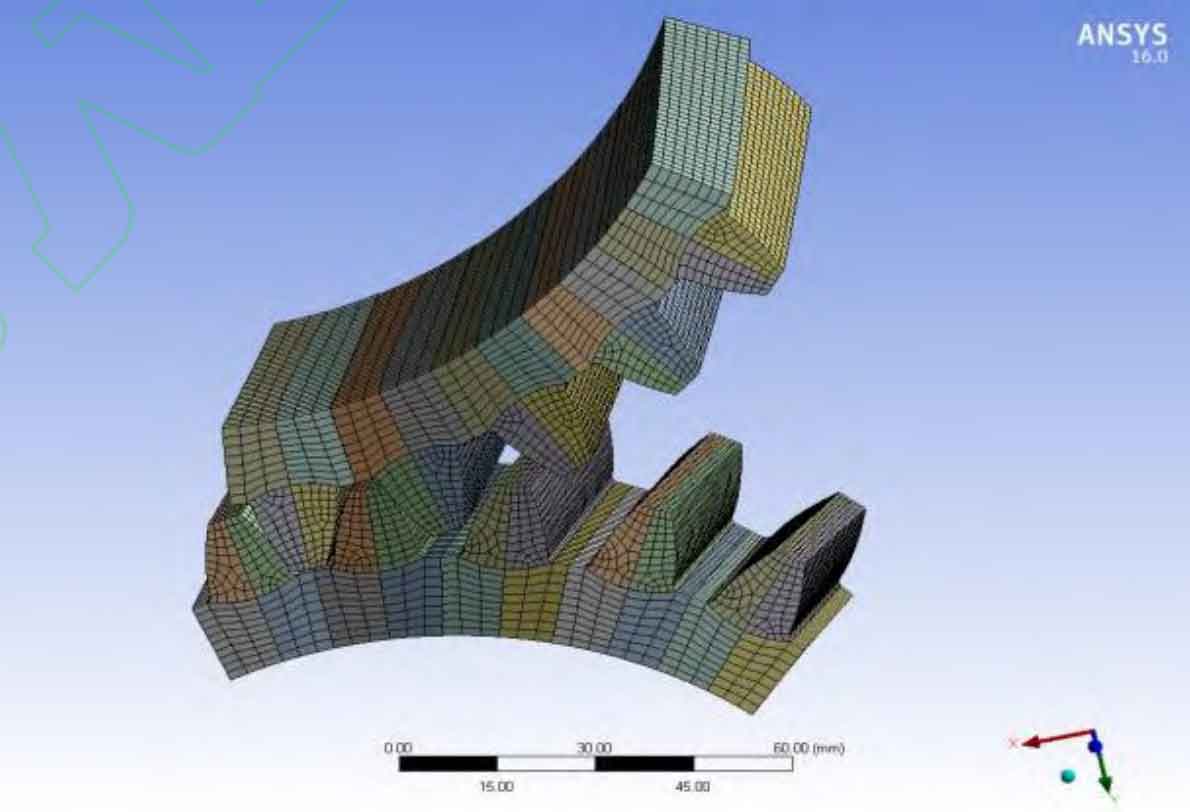

The three-dimensional assembly model of the helical gear pair transmission system established in UG is saved in x.t format, and imported into the finite element simulation software ANSYS Workbench. The five-tooth meshing model mesh of the helical gear pair finite element analysis model is established to perform the dynamic analysis of the helical gear pair.

As shown in the figure, in the finite element simulation analysis of studying the load-bearing contact characteristics of helical gear pairs, the mesh node number of the five-tooth meshing model is 223824, and the element number is 41280. In the finite element simulation model of the load-bearing contact characteristics of a helical gear pair, a rotational speed of 20 rad/s is applied to the rotating shaft of the driving wheel, and a resistance moment of 500 N · m is applied to the driven wheel. The rotational speed and torque are both constant during the operation time, and the calculation time is set to 0.3 s. The contact type is selected as frictional contact, and the selected friction coefficient is 0.1.