The finite element simulation software DEFORM-3D is used to simulate the forging process of “one fire two forging” of planetary gears, and the simulation process parameters are listed in the table. The purpose of pre forging simulation is to study the influence of preform size on metal flow law and determine the optimal preform size. The purpose of the final forging simulation is to verify whether the shape and size of the designed pre forging are appropriate, and to analyze the filling form of the tooth cavity.

| Process parameters | Pre forging | Final forging |

| Initial forging temperature of workpiece ℃ | 1100 | 800 |

| Mold preheating temperature ℃ | 300 | 300 |

| Upper mold speed mm/s | 150 | 150 |

| Reduction per step mm | 0.1 | 0.02 |

| Friction coefficient | 0.3 | 0.25 |

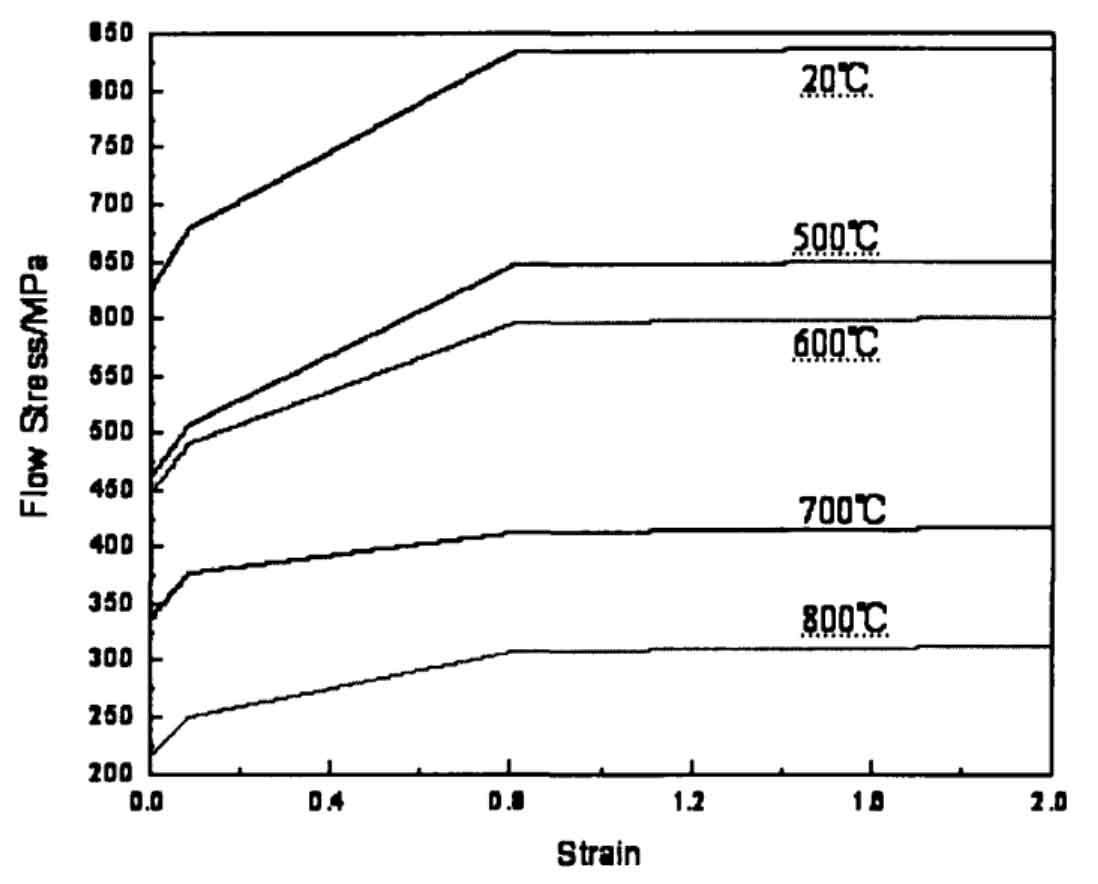

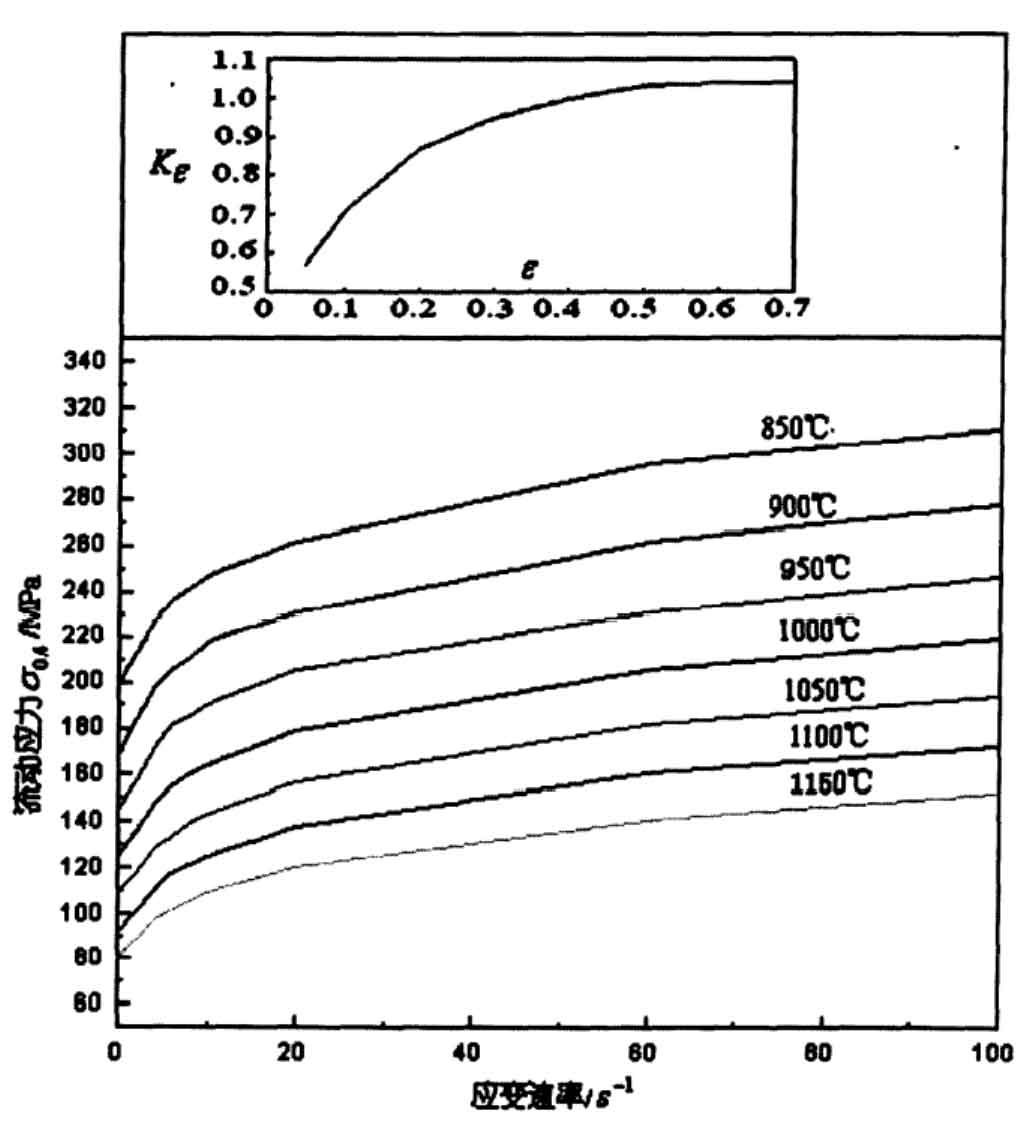

The planetary gear is made of 20CrMnTi. The finite element software DEFORM-3D is used to simulate the planetary gear forging process. It is necessary to know the flow stress of 20CrMnTi. Since the flow stress of 20CrMnTi below 800 ℃ cannot be obtained, the flow stress of 20Cr below 800 ℃ is taken as an approximate substitute for the flow stress of 20CrMnTi. Figure 1 shows the flow stress curve of 20CrMnTi at 800-1200 ℃. The flow stress curve is obtained according to the cam type high-speed deformation test in China. The flow stress calculation formula is σ= K ε σ 0.4, where σ 0.4 is the degree of deformation ε= Flow stress at 0.4, K ε Is the influence coefficient of deformation degree. Fig. 2 shows the flow stress curve of 20Cr below 800 ℃. It can be seen that the deformation rate below 800 ℃ has little effect on the flow stress.