To analyze and optimize the performance of a double arc helical gear pump, it is crucial to develop a flow field calculation model that can accurately predict the fluid flow behavior within the pump. The model should take into account the fluid dynamics, gear geometry, and motion, as well as their interactions. Here are the essential steps to build a flow field calculation model for a double arc helical gear pump:

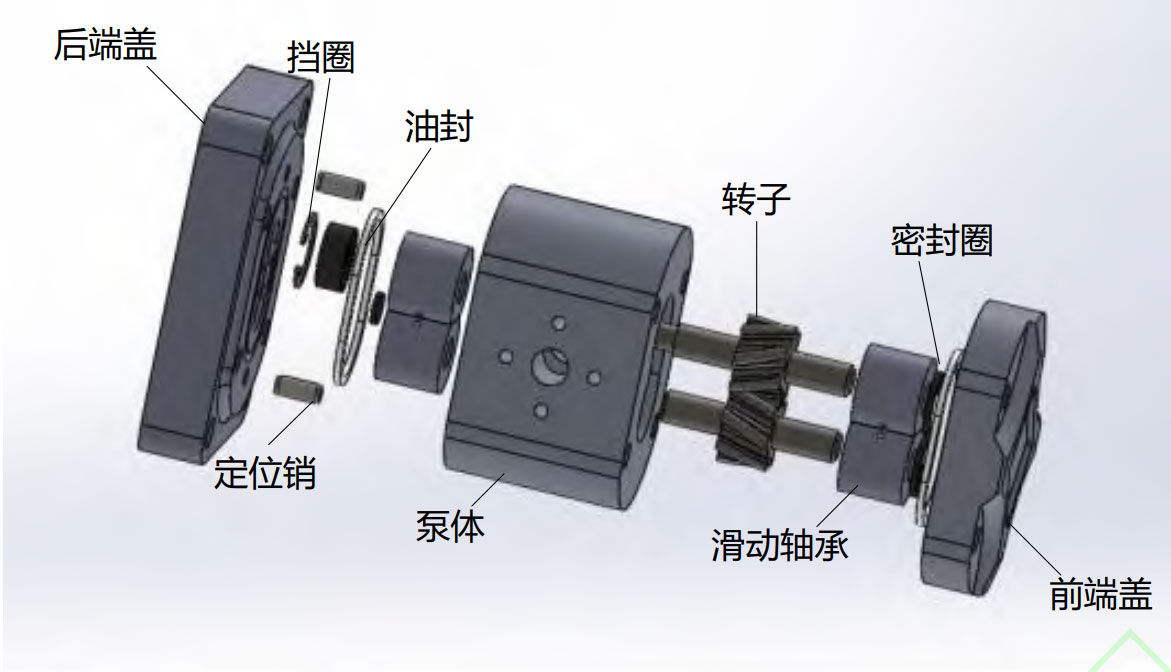

- Geometry modeling: Create a 3D model of the double arc helical gear pump, including the gears, pump casing, and other relevant components. This model should accurately represent the geometry of the helical gears, including the helix angle, tooth profile, pitch, and clearances between the gears and the pump casing.

- Mesh generation: Discretize the 3D model into a computational mesh, which will be used to solve the governing equations of fluid flow numerically. The mesh should be fine enough to capture the details of the gear geometry and fluid flow behavior accurately. Adaptive mesh refinement techniques can be employed to ensure adequate resolution in regions with high gradients, such as near the gear teeth and the casing walls.

- Governing equations: Formulate the governing equations for fluid flow within the pump, including the conservation of mass and momentum (Navier-Stokes equations). These equations need to be solved numerically to obtain the flow field within the pump. Consider the fluid’s viscosity and compressibility, as well as any additional effects such as turbulence or cavitation.

- Boundary conditions: Define the appropriate boundary conditions for the model, including the inlet and outlet pressures, rotational speed of the gears, and any wall conditions such as no-slip or slip conditions on the gear teeth and casing walls. These boundary conditions will help ensure that the model accurately represents the real-world operating conditions of the pump.

- Solver settings: Choose a suitable numerical solver and settings to solve the governing equations and obtain the flow field within the pump. The solver should be robust and efficient, capable of handling the complex geometry and fluid-structure interactions in the double arc helical gear pump.

- Post-processing and analysis: Analyze the results of the flow field calculation, including the pressure distribution, flow rates, and other relevant parameters. This analysis can help identify areas of inefficiency, potential for cavitation, or leakage within the pump. Use this information to optimize the pump design and improve its performance.

The flow field calculation model for a double arc helical gear pump can be developed and solved using computational fluid dynamics (CFD) software. The results of the model can provide valuable insights into the performance of the pump and can be used to optimize its design for better efficiency, reduced noise and vibration, and increased longevity.