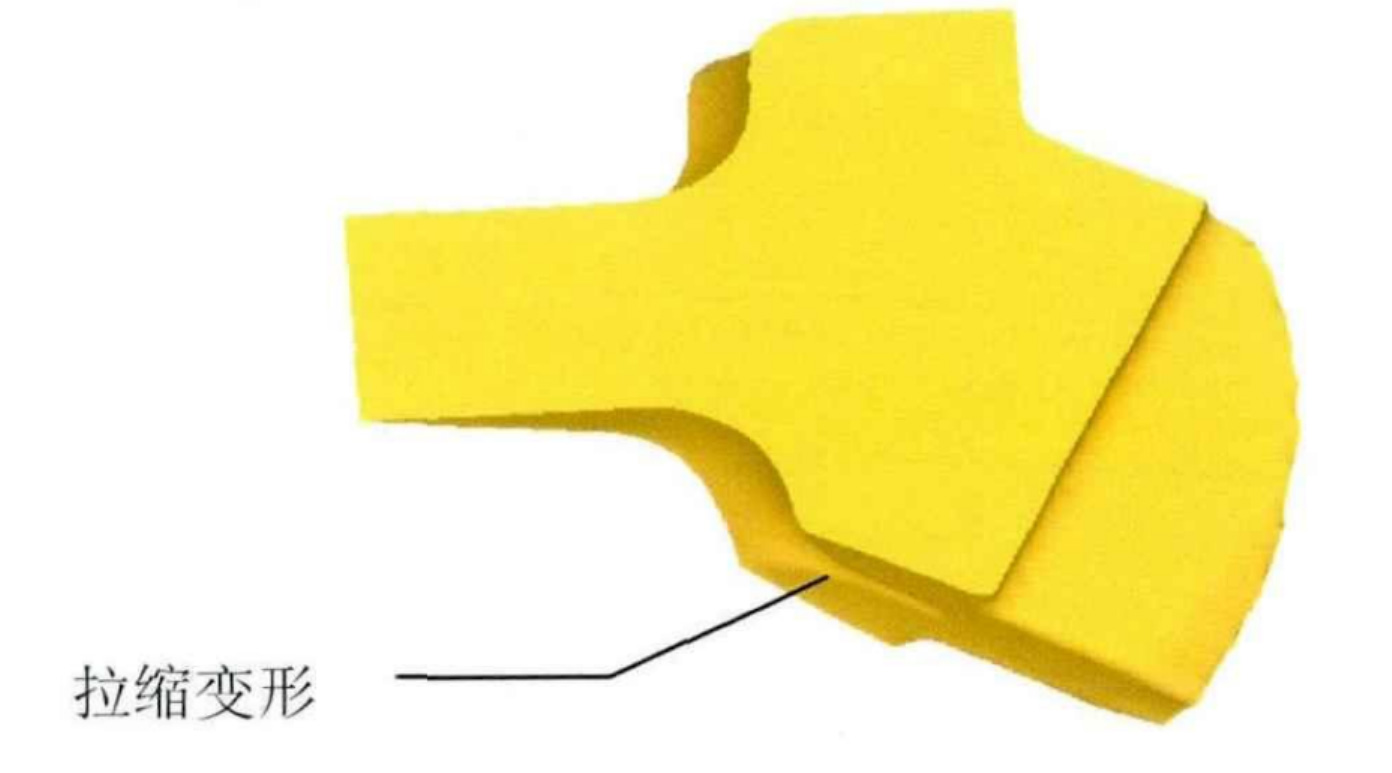

Due to the closed die forging, a complete spur bevel gear tooth profile is selected for simulation, and the cavity can be filled in 9 orthogonal tests. The effect diagram is shown in Figure 1.

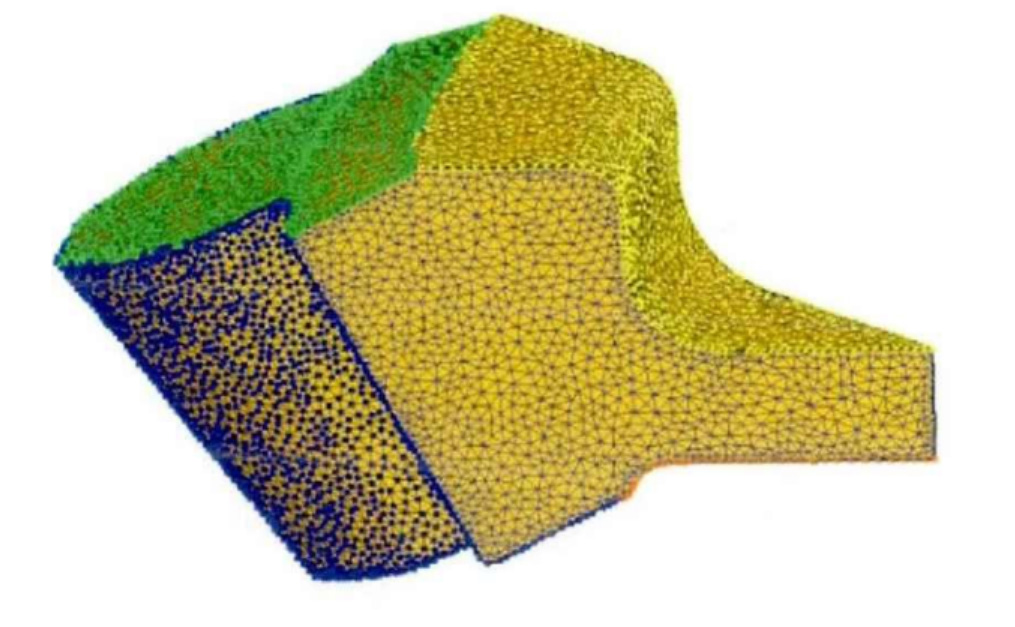

However, due to the difference of process parameters, not every test can get the straight bevel gear forgings without defects. As shown in Figure 2, the defects often occurred in the closed precision forging process are folded near the lower blind hole of the spur bevel gear forging.