There are two main machining methods of spiral bevel gears, forming method and generating method.

1.Forming method

The profile shape of spiral bevel gear machined by forming method is the same as that of gear cutting blade. For the spiral bevel gear pair with transmission ratio greater than 2.5, the tooth profile shape of the spiral bevel gear big wheel can be approximately replaced by the straight-line tooth profile, so that it can be processed by forming method. However, due to the error of the tooth profile of the spiral bevel gear processed by the forming method, the corresponding tooth profile of the matched pinion needs to be corrected by the generating method. This combined tooth cutting method is called semi hobbing method or forming method. This kind of spiral bevel gear cutting method has high production efficiency and is suitable for mass production.

2.Development method

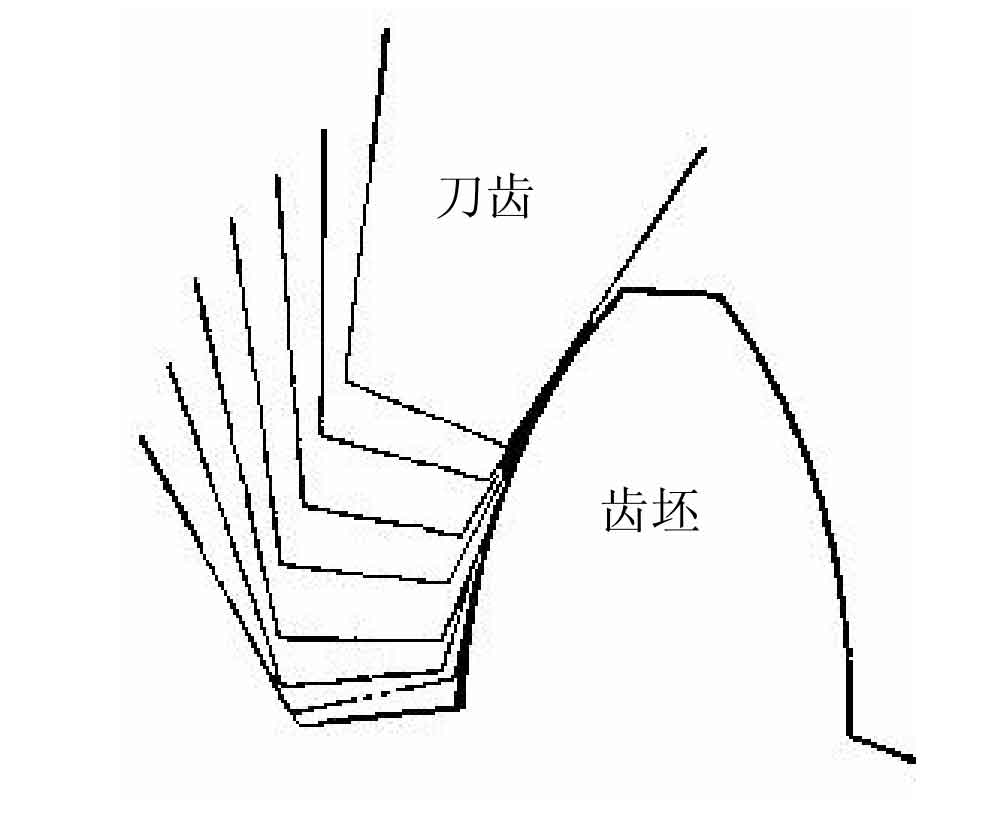

The generating method is that the high-speed rotating milling cutter head and the bevel gear to be processed roll cut according to a certain proportional relationship, and the high-speed rotating cutter teeth envelope layer by layer along the direction of tooth top to tooth root, so as to cut the tooth surface of spiral bevel gear, as shown in the figure. When using this method for gear cutting, because the width of the top of the blade is limited by the groove width of the tooth root at the small end of the spiral bevel gear to be machined, the gear cutting is generally carried out in three steps: rough cutting of the tooth groove → fine cutting (hobbing) one of the spiral bevel gear tooth surfaces → fine cutting (hobbing) the other tooth surface.

There are many methods of cutting spiral bevel gears with the combination of the above two methods. Rough machining mainly uses the double-sided edge milling cutter head to mill the convex and concave tooth surfaces of spiral bevel gear at the same time. The finishing methods mainly include single-sided cutting method, double-sided cutting method and double-sided method. The double-sided cutting method includes: double-sided tooth cutting method, fixed installation method, half rolling cutting method and spiral forming method. The characteristics, advantages, disadvantages and scope of application of these methods.