By analyzing the vertical forging process, it can be found that there are three stages from the beginning to the end of the vertical forging cone. The three stages are as follows: the first stage is that the upsetting of spiral bevel gear blank is drum stage; The second stage is the preliminary forming stage of cone head; The third stage is pit filling and complete forming of forging cone.

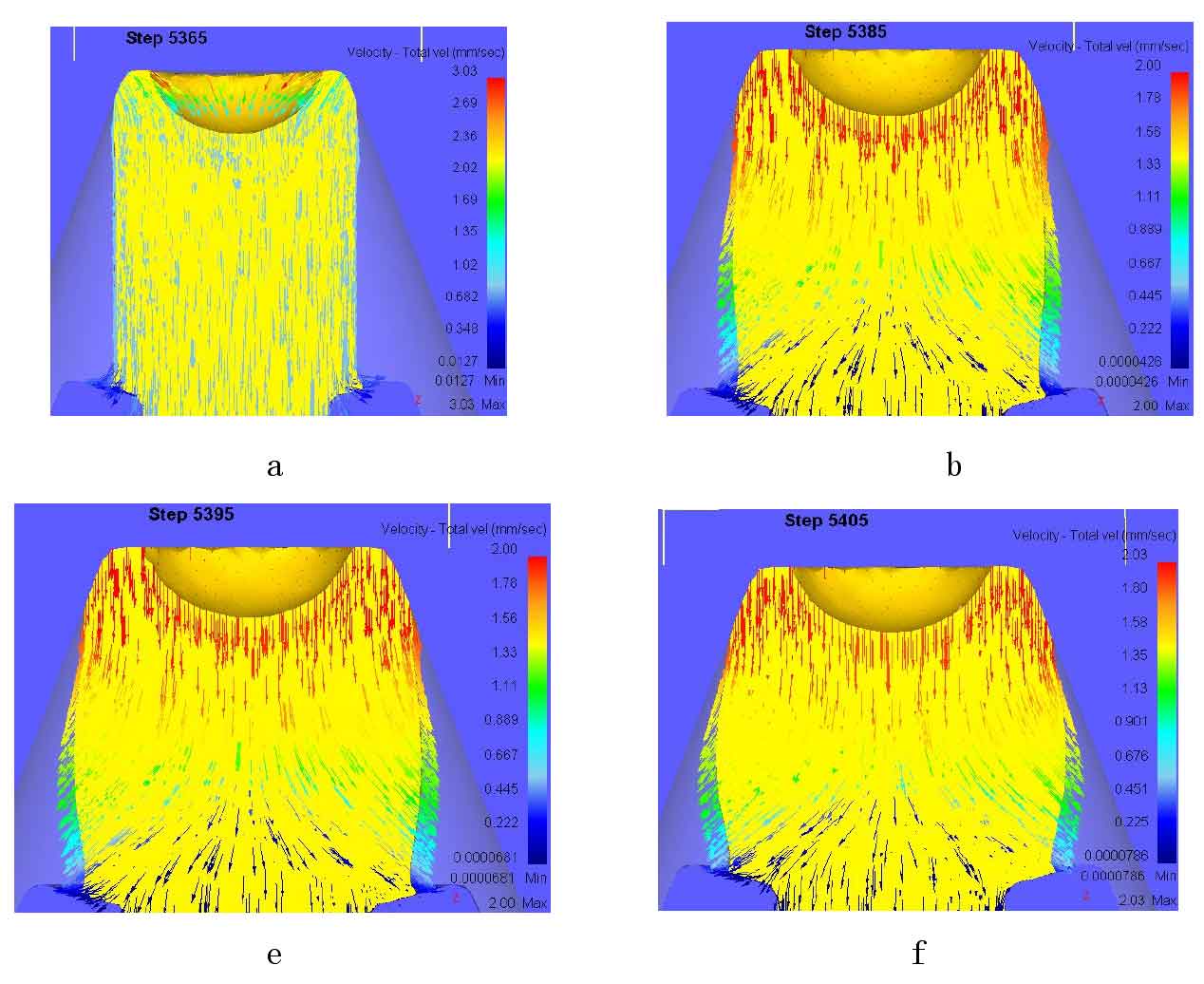

(1) The first stage: the upsetting of spiral bevel gear blank is a drum stage

Figure 1 is analyzed, in which figure a is the state when the shaft starts upsetting after touching the bottom of the lower die. At this time, the metal mainly flows downward, and the metal at the edge of the pit tends to gather towards the center of the pit. At step 5385 (Figure C), as the stroke of the upper die increases, the metal close to the lower die begins to flow to both sides. In step 5395 (Figure E), this trend is more obvious, the forging begins to show a slight drum shape, and the metal continues to flow to both sides. As shown in Figure F, under the action of continuous metal diversion to both sides, the upper end of the spiral bevel gear blank has been in a drum shape. At the same time, the metal at the top of the spiral bevel gear blank begins to contact the side wall under the constraint of the side wall of the upper die, and there is a tendency to form a cone head.

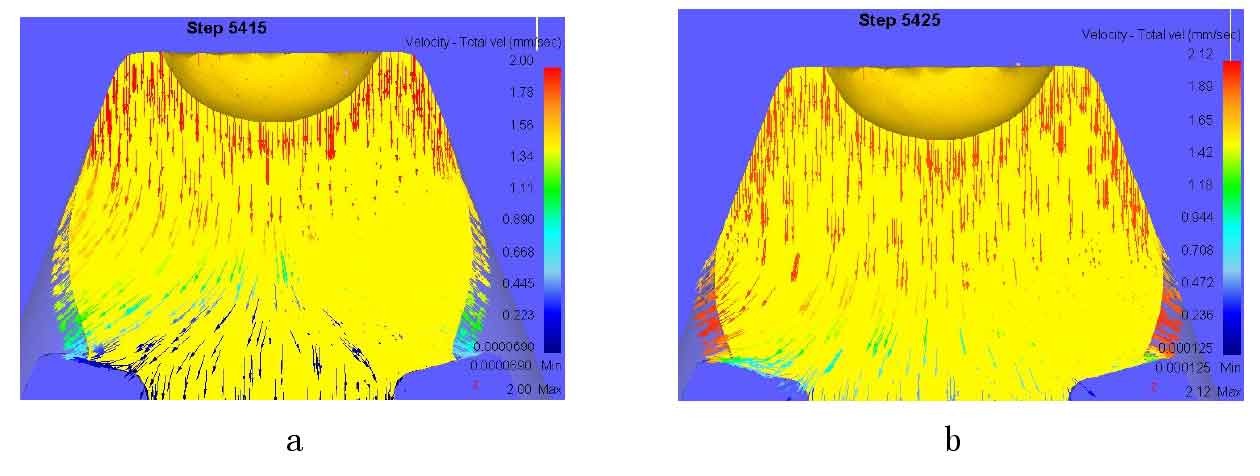

(2) The second stage: preliminary forming stage of bevel gear blank cone

By analyzing Fig. 2, it can be seen that in step 5415 (Fig. a), the metal at the top of the forging tends to divert to both sides, which is constrained by the inner wall of the upper die. It officially starts to contact the side wall of the upper die and starts to form the cone head. At the same time, the metal below that is not in contact with the side wall of the upper die is not constrained by the side wall and continues to divert to both sides. By step 5425 (Fig. b), the conical head has begun to take shape, the shunting parts on both sides of the lower metal have been greatly reduced, and the shunting state on both sides is maintained only at the gap between the upper and lower dies. At the same time, the contact area between the spiral bevel gear blank and the upper surface of the lower die has been greatly increased. As the upper die continues to go down, the forging cone head is formed in step 5431 (Figure C). Only on the parting surface, the radial size of the forging needs to be further increased. At this time, the metal near the gap between the upper and lower dies flows towards the gap direction at a high speed, so that the cone head completely meets the dimensional requirements. At this time, the metal no longer flows to both sides, but flows downward with the downward pressure of the upper die. Step 5434 (Figure d): the cone head is completely formed, and the contact area between the spiral bevel gear blank and the upper surface of the lower die also reaches the edge of the upper surface of the lower die. The metal at the gap edge of the upper and lower dies continues to flow in the gap direction, and the metal flow speed in the bevel head of spiral bevel gear blank decreases. The central metal flow line begins to become sparse, while the metal flow line in the inner area near the edge of the pit begins to become dense, which is the phenomenon of filling the pit.

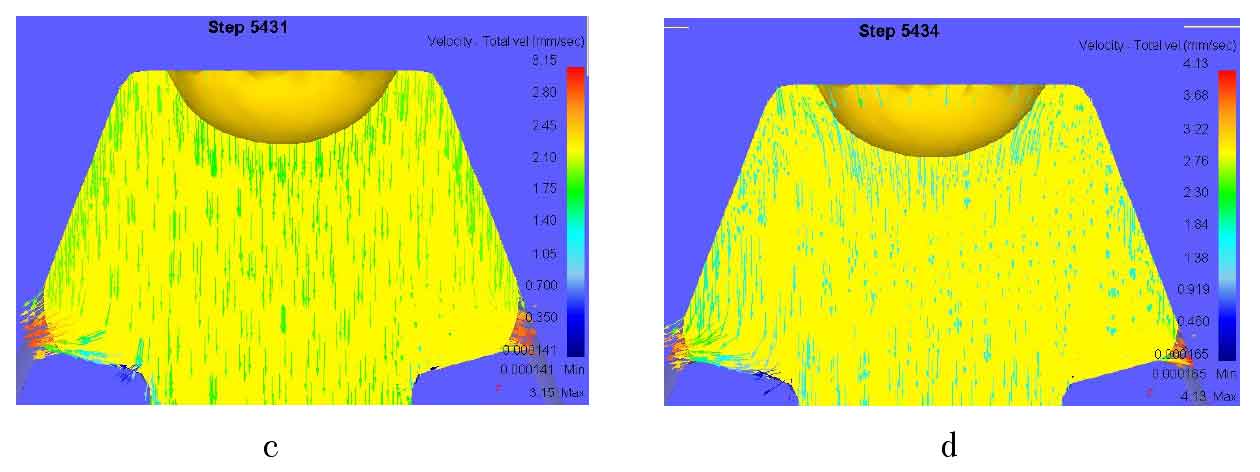

(3) The third stage: pit filling and cone forming

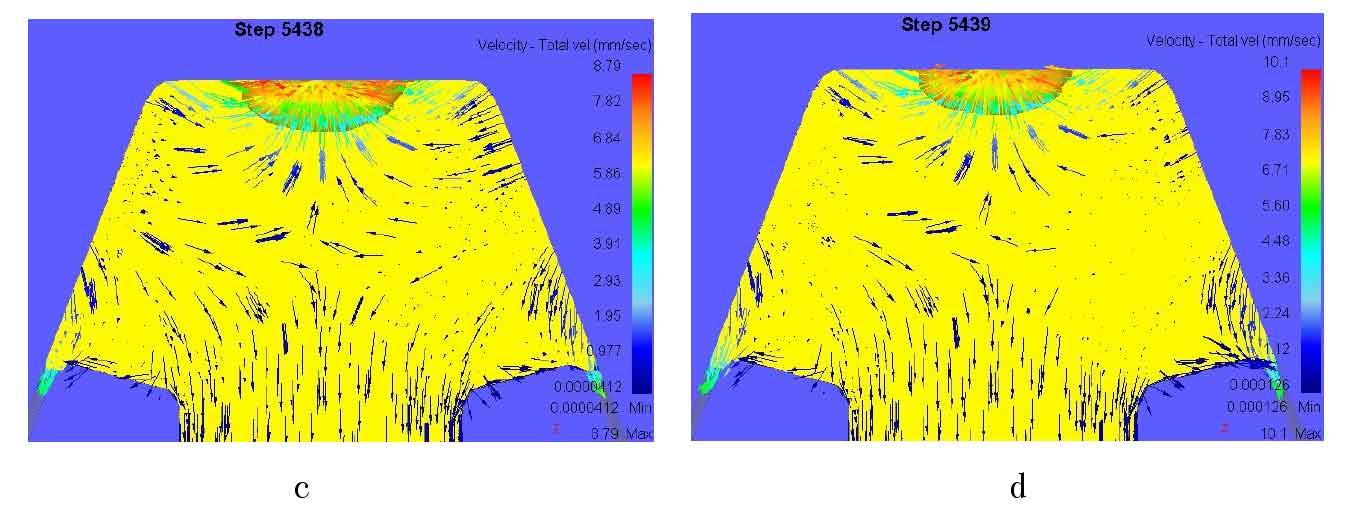

Figure 3 shows in detail the pit filling process in the vertical forging process. From step 5434 to step 5435, the metal flow trend changes suddenly. In step 5435 (figure a), the generation of micro burrs at the gap between the upper and lower dies increases the metal flow resistance inside the bevel gear blank cone head. At this time, the conditions for filling the pit are met. The metal near the pit inside the cone head begins to flow back towards the pit, and the metal in the upper half of the bevel gear blank cone head flows back from both sides to the center, The metal in the local area below the pit flows upward. In this trend, at step 5437 (Fig. b), only two steps short, and the pit has been significantly reduced compared with step 5435, indicating that the filling speed is very fast.

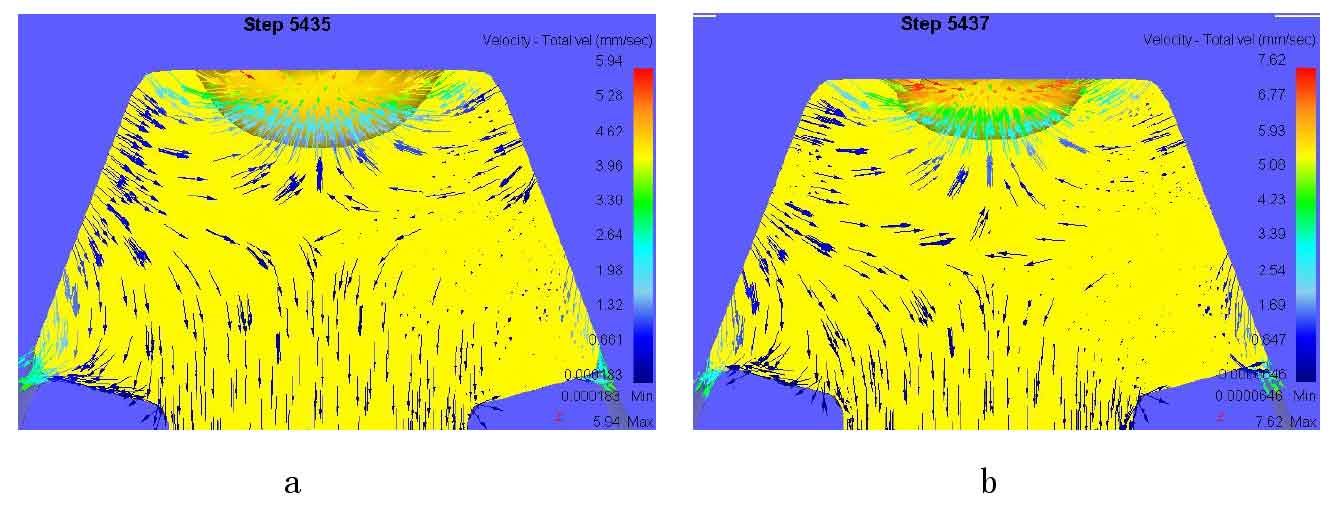

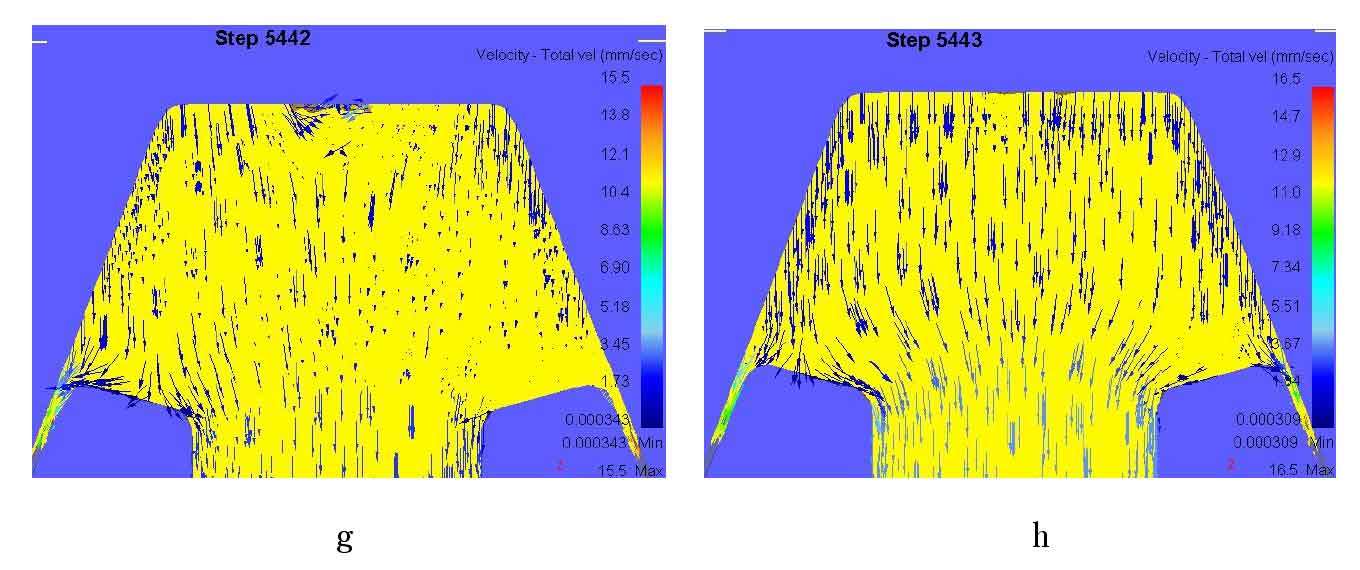

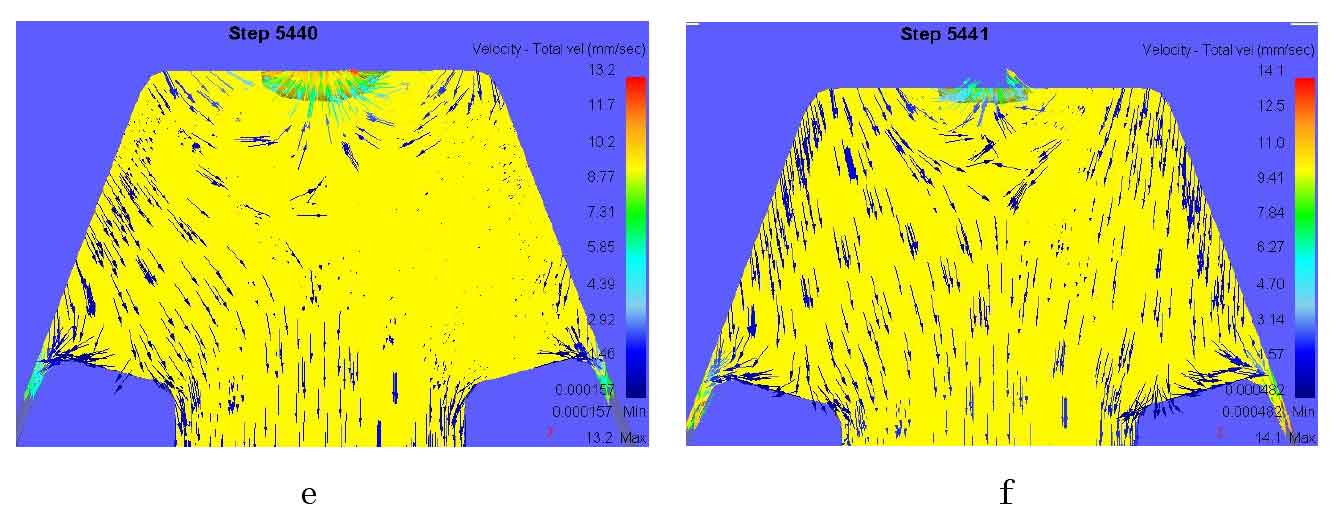

As the upper die stroke increases, this flow trend continues in step 5439 (Figure d), and the pit continues to decrease. In step 5440 (Figure E), the reduction of the pit increases the resistance of the metal to flow there. It can be seen from the figure that the metal flow to the pit is not as strong as that in step 5435. At the same time, the metal flow to the gap between the upper and lower dies continues to meet the conditions for filling the pit. In step 5441 (Fig. f), the pit has become very small. At this time, only in the local area below the small pit, the metal flows to the pit direction. On the whole, the metal inside the bevel gear blank cone changes to flow downward. In step 5442 (Fig. g), the pits have basically disappeared, and only a small amount of pits are left. The metal inside the conical head of spiral bevel gear blank starts to be squeezed into the gap between the upper and lower dies quickly under the influence of the pressing down of the upper die, resulting in a large number of flash. In step 5443 (Figure h), the concave point disappears. So far, the concave pit has been completely filled, the bevel gear blank cone head has been fully formed, and the metal inside the cone head has fully recovered to flow downward with the pressing of the upper die. From the whole pit filling process, the time from the beginning of filling to the complete disappearance of the pit is only 8 steps from 5435 to 5443, each step is 0.2S, and the pit filling is completed quickly in about 1.5s.

Based on the above analysis, it can be found that the filling of the pit requires the flow resistance of the internal metal to reach certain conditions. In the early upsetting and cone forming stage, the pit maintains the original shape and size. After the formation of the bevel gear blank cone, the flow of the metal to the gap between the upper and lower dies is blocked. At this time, the filling conditions of the pit are met, and the pit begins to fill rapidly. With the continuous increase of flash, the resistance of metal flow also increases, This also constantly provides conditions for the filling of pits, so the pits are completely filled in 1.5s. It is concluded that the order of the resistance of metal flow during the forming of cone head is: flash generates pit filling, forming and upsetting of cone head.