There are some defects in the process of die forging, such as insufficient mold filling and cracks. In order to overcome the limitation of traditional mechanical gear production only relying on experience, and achieve the goals of good filling, small deformation force and high service life of the die forging process, the mechanical gear die forging forming was simulated and analyzed, and the distribution rules of load, failure coefficient and equivalent stress in the forming process of mechanical gear were analyzed, which were the process parameters of mechanical gear in the actual forming process Numerical optimization and process improvement provide theoretical basis and technical support.

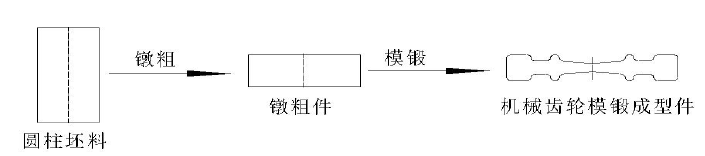

The research of mechanical gear forging mainly includes upsetting and die forging. The corresponding mechanical gear forging is shown in the figure.

It can be seen from the figure that in the process of mechanical gear die forging, the cylindrical blank is formed into a upsetting part under the upsetting process, and the formed upsetting part is formed into the target mechanical gear die forging under the die forging forming process.