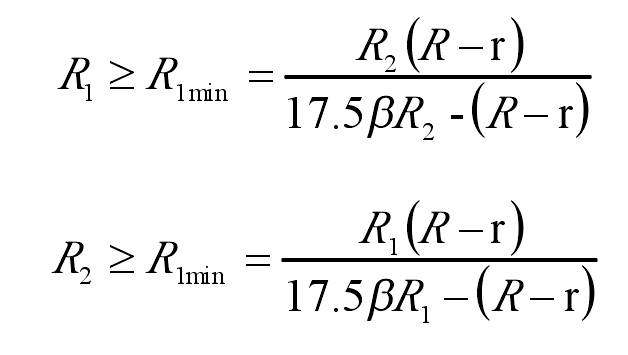

Drive roll and core roll are the main ring rolling dies for the forming of spiral gear blank, and their diameter also directly affects the forming quality of ring rolling. The radius of spiral gear blank forming die of drive roll and core roll has the following relationship conditions, namely:

R1min and r2min are the minimum radii of the driving roll and core roll dies.

The above formula only defines the minimum radius of the working die, and its maximum radius is determined by the ring rolling machine and the inner diameter of the ring blank. The driving roller is installed on the ring rolling machine, and its maximum working diameter is limited by the conditions of the ring rolling machine. Because the center distance between the driving roller and the core roller of the ring rolling machine has a range value, the maximum working diameter of the driving roller should meet this range. Secondly, the maximum radius of the core roll is not allowed to exceed the radius of the inner ring of the spiral gear blank, otherwise the spiral gear blank will not be placed on the core roll.