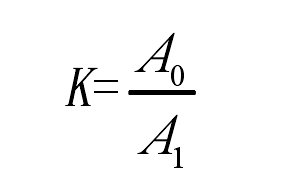

The ring rolling ratio is the most important parameter in the forming process parameters. It shows the pRing rolling ratio is the most important parameter in the forming process parameters of cylindrical gear blank. It shows the plastic deformation degree of cylindrical gear blank from a macro perspective. It represents the ratio of cross-sectional area A0 before ring rolling and cross-sectional area A1 after ring rolling of cylindrical gear blank:

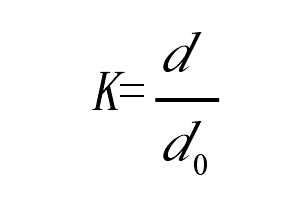

The ring rolling ratio mainly reflects the deformation of the blank during processing. Generally, in order to The ring rolling ratio mainly reflects the deformation of the cylindrical gear blank during processing. Generally, in order to facilitate calculation, it is often expressed by the ratio of the aperture of the ring before and after ring rolling. This calculation method is often applicable to the rectangular ring with simple section, which is recorded as:

Where d0 and D respectively represent the aperture before and after the ring rolling.

The formula shows that the hole diameter after ring rolling remains unchanged. When the ring rolling ratio is increased, the inner hole diameter of the blank before ring rolling decreases and the wall thickness of the ring increases, which prolongs the processing time. In general, the value of K takes the larger value aThe formula shows that the hole diameter after ring rolling remains unchanged. When the ring rolling ratio is increased, the inner hole diameter of cylindrical gear blank before ring rolling decreases and the wall thickness of cylindrical gear blank increases, which prolongs the processing time. In general, the value of K takes the larger value and the smaller value with the increase of the outer circle diameter of the ring. The ring ratio required for the forming of cylindrical gear blank ring rolling cannot be too large, which is about 1.3-1.9, and most of them take about 1.5.