The starting motor drive gear material is 20CrMnTi, and the heat treatment process is normalizing quenching and tempering carburizing quenching and tempering. This paper analyzes the fracture morphology, chemical composition, metallography and mechanical properties of the driving gear of the starting motor, and analyzes the stress state of the driving gear, so as to explore the fracture causes of the driving gear and prevent the recurrence of such faults.

1. Macroscopic observation of fracture

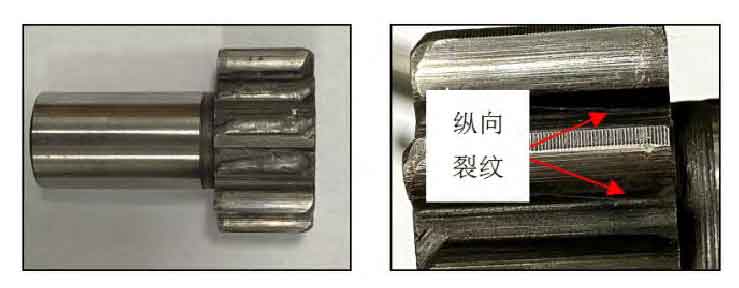

The three teeth of the driving gear of the starting motor are broken from the tooth root as a whole, as shown in Figure 1. Longitudinal cracks of different lengths appear on the tooth root of other unbroken teeth, as shown in Figure 2. There are different degrees of wear marks on the end face of the gear.

2. SEM analysis of fracture

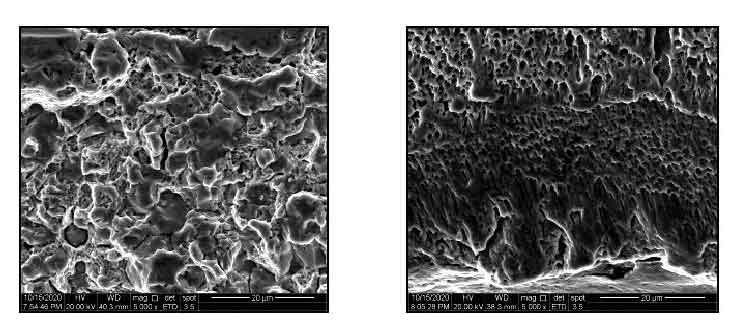

The fracture surface was detected by scanning electron microscope (SEM). The crack source of tooth root was characterized by intergranular dimple, as shown in Fig. 3. The final fracture zone was characterized by equiaxed dimple and shear dimple, as shown in Fig. 4. There was no fatigue crack and no fatigue feature.

3. Chemical composition analysis

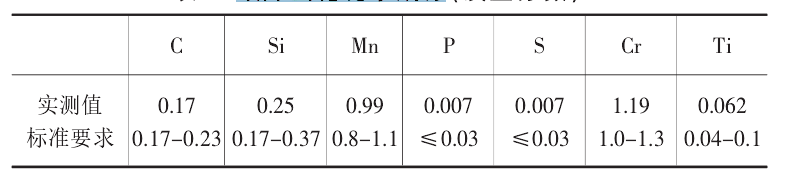

The chemical composition of the gear material is tested and analyzed. The results are shown in Table 1. According to the GB / T 3077 standard, the chemical composition of the gear meets the requirements of the standard.