The friction coefficient is affected by lubrication. The better the lubrication effect is, the smaller the friction coefficient is. The size of the friction coefficient directly affects the quality of deformation. The smaller the friction coefficient, the smaller the stress, the better the metal flow and the more uniform the deformation effect. In the processing process, the existence of friction is also conducive to the plastic deformation of the blank, so it is necessary to comprehensively consider, reasonably design the lubrication and determine the friction coefficient. In addition, the friction coefficient required by different positions of the blank is different, so it is necessary to find out the friction demand under different conditions.

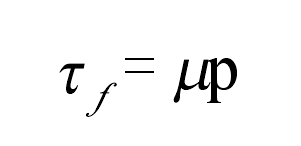

In addition, there are two kinds of friction models, one is Coulomb’s law model and the other is shear model. The former maintains a constant friction coefficient µ during processing. When the normal stress borne by the blank is p, the shear stress generated by friction τ F is:

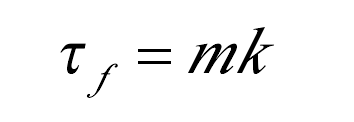

When the load on the blank surface is transmitted through the lubricant on the end face, this situation conforms to the Coulomb’s law model, but the deformation of the blank in processing is very complex and the pressure is very large. At this time, the Coulomb’s law model is no longer applicable. In addition, the friction force has a certain range, and it is not allowed to exceed the shear strength K, where σ Is the yield stress. The shear model, also known as plastic friction, is expressed as:

Where m is the friction factor. In this case, the contact stress is not considered, so it is usually applied to the forging process. The value range of M is between 0 and 1. Although the value range is very small, it is affected by temperature, processing method, mechanical equipment and other relevant factors. Therefore, the value of friction factor M is not simple, and it needs to be taken into account comprehensively and reasonably. At the same time, both friction cases need two existence conditions, one is Coulomb friction condition, the other is normal friction condition.

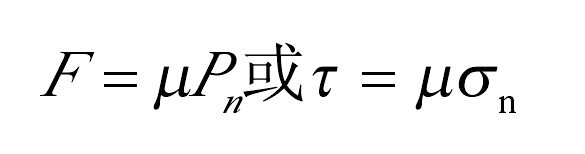

(1) Coulomb friction condition

When there is no adhesion on the contact surface of the blank under the action of friction, the Coulomb friction model is used to calculate the friction. From the formula, it can be seen that the friction is directly proportional to the contact positive pressure, that is, the existing relationship formula is:

Among them,

F – friction force;

τ — Friction shear stress;

µ – friction coefficient;

σ N – positive compressive stress on the contact surface of the blank.

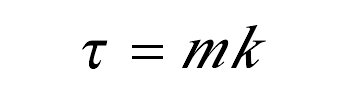

(2) General friction condition

Under this condition, the friction shear stress on the blank surface is directly proportional to the yield strength of the blank material in the shear direction, and the relationship is as follows:

Where, M is the friction coefficient, the value range is 0 ≤ m ≤ 1, and K is the yield strength.