Friction between the metal die and the forging die is inevitable. Friction in metal plastic forming mainly has the following characteristics:

1) The friction in the plastic forming process is caused by the metal flow. The irregular metal flow leads to the difference of friction at each point on the contact surface, and the contact surface between the metal and the die is larger and larger in the flow process, which increases the friction.

2) Due to the need of metal plastic forming, deformed metals are usually formed in hot state, so friction often occurs with high temperature, which puts forward higher requirements for lubricants.

Although sometimes friction can be used in open die forging, roll forging and other processes to control the flow direction of metal, in general, friction is unfavorable to the plastic forming of metal. The existence of friction will make it difficult for metal flow and lead to uneven internal structure of formed parts. In addition, friction will wear the die bore and make the die invalid. In view of the many adverse effects of friction on plastic forming, it is very necessary to take appropriate lubrication measures to reduce friction.

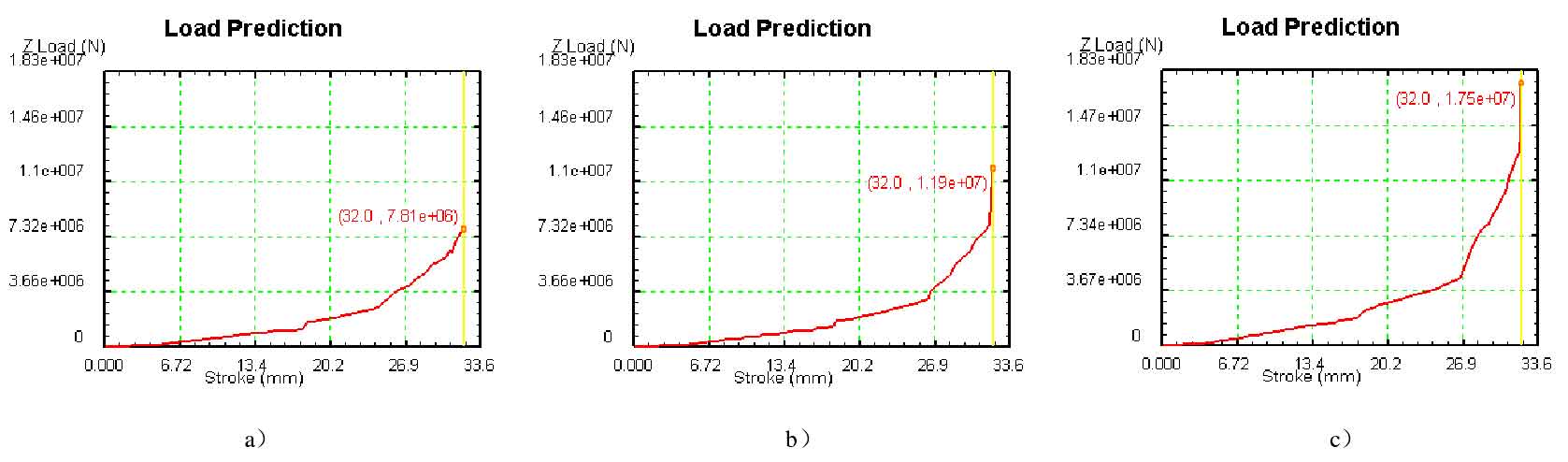

In order to study the influence of friction conditions on the precision forging of spiral bevel gear, under the condition of forming temperature of 1150 ℃ and forming speed of 200mm / s, three shear friction models with friction factors of 0.1, 0.3 and 0.7 are used to simulate the precision forging process of spiral bevel gear, and the load stroke curve is obtained, as shown in Fig. 5-15.

It can be seen from the load stroke curve that the worse the lubrication conditions (i.e. the greater the friction factor), the greater the load during the forming of spiral bevel gear. When the friction factor is 0.7, the forming load is increased by 124% compared with that when the friction factor is 0.1, and when the friction factor is 0.3, the forming load is increased by 52% compared with that when the friction factor is 0.1. It can be seen that good lubrication conditions can greatly reduce the forming load, promote the plastic deformation of metal and prolong the service life of die. Therefore, during the precision forging of spiral bevel gear, water graphite should be used to lubricate the die well to ensure the smooth forming of forgings.