Designing a gearbox with complex gear systems can be challenging, but a gear calculator can simplify the process and ensure accurate results. Here’s how to use a gear calculator for gearbox design:

- Understand Gearbox Requirements: Start by understanding the requirements of your gearbox, such as the desired gear ratios, torque and speed requirements, and available space constraints. This information will guide your design process and help you select appropriate gears.

- Select the Gear Calculator: Choose a gear calculator that specifically supports gearbox design. Look for features such as multiple gears, different gear types (spur, helical, bevel, etc.), and the ability to calculate overall gear ratios. This will allow you to accurately model and analyze your gearbox.

- Input Gear Parameters: Input the parameters for each gear in your gearbox. This includes the number of teeth, gear module, pressure angle, and any other relevant specifications. Input the driving gear first and then proceed to the driven gears.

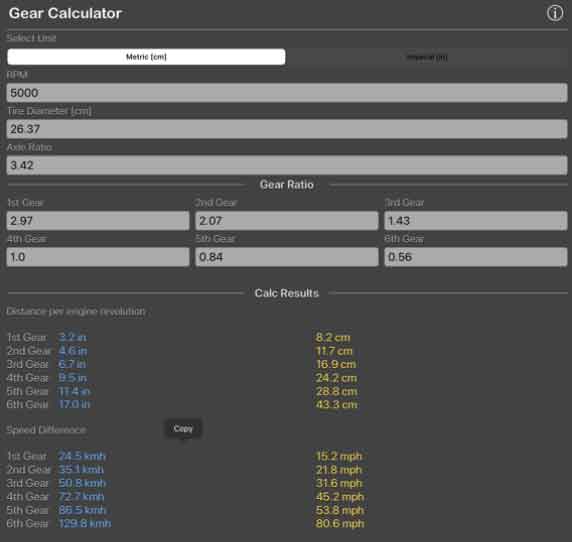

- Calculate Gear Ratios: Once you’ve input the gear parameters, the gear calculator will calculate the individual gear ratios between each pair of gears. It will also provide the overall gear ratio for the entire gearbox. Ensure that the calculated gear ratios meet your requirements and make adjustments if necessary.

- Analyze Gear Interactions: Use the gear calculator to analyze the interactions between the gears in your gearbox. It can provide information on tooth contact patterns, load distribution, and potential issues like interference or edge contact. Analyzing these interactions will help you optimize the design for smooth and efficient gear meshing.

- Evaluate Efficiency: The gear calculator can estimate the efficiency of your gearbox based on factors such as tooth profiles, friction, and lubrication conditions. Evaluate the efficiency values to identify areas for improvement and make design adjustments accordingly.

- Validate Design with Simulation: Some gear calculators offer simulation capabilities that allow you to visualize and simulate the behavior of your gearbox. Use this feature to validate your design, observe the gear interactions, and ensure that the gearbox operates as intended.

- Iterate and Optimize: Gearbox design is an iterative process. Use the gear calculator to make adjustments to gear parameters, gear ratios, or other design elements based on the analysis and simulation results. Iterate on the design and continue refining it until you achieve the desired performance and functionality.

- Consider Constraints and Standards: While using the gear calculator, consider any constraints or standards that apply to your gearbox design. For example, consider factors like backlash, gear module limitations, material selection, and lubrication requirements. Ensure that your design adheres to the necessary constraints and meets applicable standards.

- Documentation and Reporting: Finally, document your design and create reports based on the calculations and analysis performed using the gear calculator. This documentation will serve as a reference and help communicate your design decisions to others involved in the gearbox manufacturing or assembly process.

By utilizing a gear calculator designed for gearbox systems, you can simplify the complex task of designing a gearbox. The calculator will assist you in accurately calculating gear ratios, analyzing gear interactions, optimizing efficiency, and simulating the gearbox behavior. This streamlined approach will save time, enhance accuracy, and lead to well-designed and efficient gearbox systems.