The gear calculator is a valuable tool for making informed decisions and optimizing gear systems. It provides critical information and analysis that can guide you towards the most efficient and effective gear system design. Here’s how a gear calculator can help you make informed decisions for gear system optimization:

- Design Parameter Analysis: A gear calculator allows you to input various design parameters such as gear module, pressure angle, number of teeth, and center distance. By analyzing these parameters, the gear calculator provides insights into the gear system’s behavior and performance. You can evaluate different design options and make informed decisions based on the calculated results.

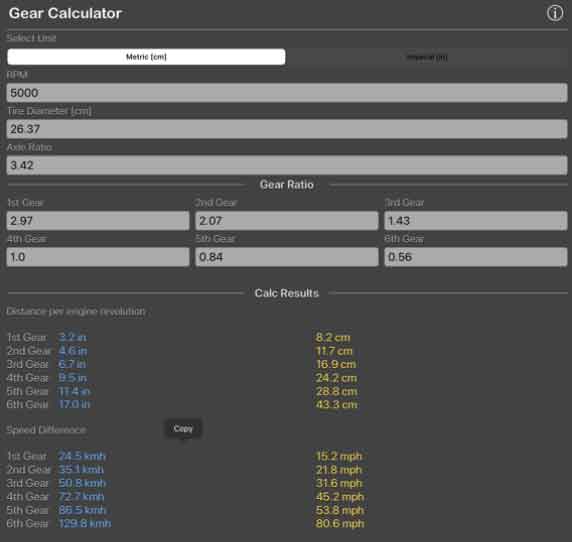

- Gear Ratio Optimization: The gear calculator enables you to calculate and optimize the gear ratios within your system. By adjusting the number of teeth on the driving and driven gears, you can achieve the desired speed reduction or speed increase. The gear calculator helps you evaluate different gear ratio configurations, allowing you to select the most suitable option for your specific application.

- Load Distribution Analysis: Gear calculators provide load distribution analysis, which helps you assess how the load is distributed across the gear teeth. This analysis is crucial for ensuring even load sharing and preventing premature wear or tooth failure. By evaluating load distribution, you can make informed decisions on gear dimensions, tooth profiles, and modifications to optimize load distribution and enhance the gear system’s efficiency and durability.

- Efficiency Estimation: Gear calculators can estimate the efficiency of the gear system based on various factors such as tooth profile, friction, lubrication conditions, and mechanical losses. These efficiency estimates allow you to compare different design options and identify areas for improvement. By considering the calculated efficiency values, you can make informed decisions to optimize the gear system for higher efficiency and reduced power losses.

- Contact Analysis: Gear calculators provide contact analysis, allowing you to assess the contact pattern between gear teeth. This analysis helps identify potential issues such as edge contact, tooth interference, or excessive contact stresses. By evaluating the contact pattern, you can make informed decisions on tooth modifications, gear profile adjustments, or gear alignment to ensure proper gear meshing and minimize frictional losses.

- Material Selection: Gear calculators assist in material selection by considering factors such as load, speed, and operating conditions. They help you determine the appropriate material properties required for optimal gear performance, such as strength, hardness, and wear resistance. With the gear calculator’s input, you can make informed decisions about the choice of materials that will maximize the gear system’s efficiency and durability.

- Simulation and Visualization: Some advanced gear calculators offer simulation capabilities, allowing you to visualize the gear system’s behavior and performance. These simulations help you understand how different design decisions impact the gear meshing, load distribution, and efficiency. By visualizing the simulated results, you can make informed decisions and iterate on the design to achieve the desired gear system optimization.

By utilizing a gear calculator, you can make informed decisions at each stage of the gear system design process. From selecting the appropriate gear ratios and tooth profiles to optimizing load distribution and estimating efficiency, the gear calculator empowers you to optimize the gear system for maximum performance and efficiency. It enables you to explore different design options, evaluate their impact, and make well-informed decisions to achieve the desired gear system optimization.