Gear design and analysis are complex processes that involve various parameters and calculations. A gear calculator can be a valuable tool to aid in designing and analyzing gears. Here’s a comprehensive guide to using a gear calculator for gear design and analysis:

- Gear Parameters: Start by gathering the necessary information about the gear system, such as the input and output speeds, power requirements, torque values, and desired gear ratios. These parameters will serve as the basis for the calculations in the gear calculator.

- Gear Types and Configuration: Determine the type of gear system you’re working with, such as spur gears, helical gears, bevel gears, or worm gears. Identify the gear configuration, such as parallel shaft, crossed axis, or planetary, depending on the specific application.

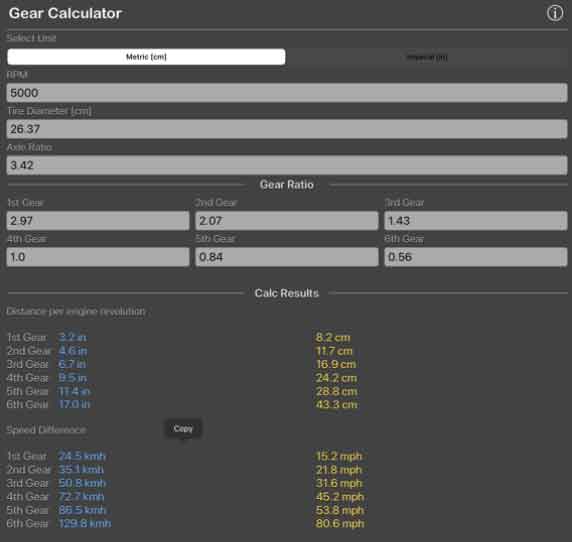

- Gear Ratio Calculation: Calculate the required gear ratio based on the desired output speed and the input speed. The gear ratio is the ratio of the number of teeth between the input and output gears.

- Pitch Diameter Calculation: Determine the pitch diameter of the gears based on the gear ratio, center distance between the gears, and the number of teeth. The pitch diameter is the diameter at which the gear teeth theoretically mesh.

- Module or Diametral Pitch Selection: Choose the appropriate module (metric) or diametral pitch (imperial) based on the desired gear size and tooth strength. The module or diametral pitch determines the tooth size and spacing.

- Tooth Profile Calculation: Calculate the tooth profile parameters, such as the addendum, dedendum, tooth thickness, and clearance. These parameters are essential for proper gear meshing and tooth engagement.

- Gear Forces and Load Analysis: Analyze the gear forces and loads to ensure that the gears can handle the transmitted power and torque. Consider factors such as bending stress, contact stress, and dynamic loads. Use the gear calculator to determine the maximum allowable stresses and compare them to the calculated stresses.

- Gear Material Selection: Based on the calculated stresses, select a suitable gear material that can withstand the required loads and provide the desired durability and wear resistance. Consider factors such as strength, hardness, fatigue resistance, and heat treatment options.

- Efficiency and Power Loss Calculation: Calculate the gear efficiency to assess the power losses due to friction and other factors. This helps in evaluating the overall system efficiency and optimizing the gear design for better performance.

- Additional Calculations: Depending on the specific requirements of the gear system, there may be additional calculations to consider. These could include backlash calculation, gear tooth contact analysis, wear estimation, and lubrication analysis.

Remember that a gear calculator is a tool that assists in the design and analysis process, but it is important to validate the results and perform real-world testing and validation of the gear system. Additionally, consider any relevant industry standards and guidelines for gear design and analysis.

There are various software applications and online gear calculators available that provide automated calculations and simulations for gear design and analysis. These tools simplify the process and help in visualizing the gear system’s performance under different operating conditions.