Gear forging plays a crucial role in addressing the challenges of high torque transmission in electric vehicles (EVs). EVs require efficient and reliable gear systems to transmit the high torque generated by electric motors to the wheels. Let’s explore how gear forging meets these challenges and contributes to the development of gear systems for electric vehicles:

- High Torque Handling: Electric vehicles often generate high torque from their electric motors, especially during acceleration or when climbing steep gradients. Gear forging provides the necessary strength and durability to handle these high torque loads. Forged gears offer superior mechanical properties, including high tensile and fatigue strength, enabling them to withstand the torque requirements of electric vehicles without deformation or failure.

- Weight Optimization: Electric vehicle manufacturers strive to reduce weight to enhance range and overall efficiency. Gear forging allows for the production of lightweight gears without compromising strength. By optimizing the material distribution and removing excess material through the forging process, forged gears achieve weight savings, contributing to the overall weight reduction of the vehicle.

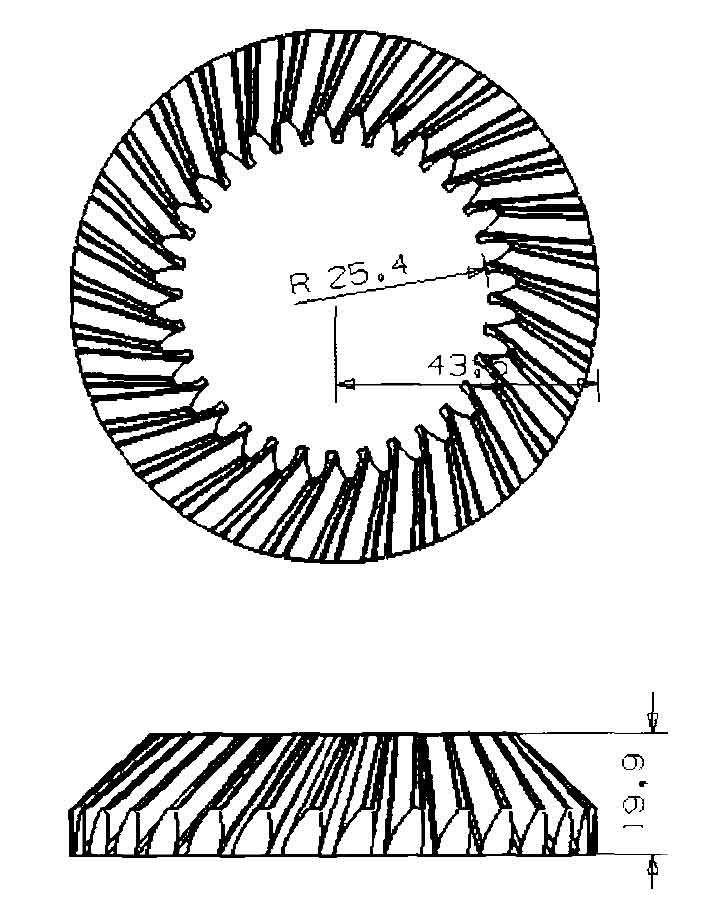

- Compact Design: Electric vehicles often require compact gear systems to fit within the limited space available. Gear forging enables the production of gears with complex and compact geometries. The near-net shape capabilities of forging processes allow for the creation of gears with precise tooth profiles and tight dimensional tolerances, facilitating the design of compact and efficient gear systems for electric vehicles.

- Noise and Vibration Reduction: Electric vehicles are known for their quiet operation, and minimizing gear noise is crucial to maintaining a pleasant driving experience. Forged gears can be designed with optimized tooth profiles and surface finishes to reduce noise and vibration. The precise manufacturing process of gear forging ensures accurate tooth meshing and minimizes gear misalignment, contributing to quieter gear operation in electric vehicles.

- Efficiency and Energy Optimization: Gear forging contributes to improving the overall efficiency and energy optimization of electric vehicles. By producing gears with precise tooth profiles, forging minimizes friction and energy losses during gear meshing, leading to improved overall system efficiency. The high-quality surface finish achieved through forging reduces friction and enhances the gear’s ability to transmit torque efficiently, resulting in optimized energy usage and increased range for electric vehicles.

- Thermal Management: Electric vehicle gear systems can experience high operating temperatures due to the continuous power delivery and regenerative braking. Gear forging allows for the use of materials with excellent thermal resistance and superior heat dissipation properties. The enhanced material properties and optimized cooling channels in forged gears ensure effective thermal management, minimizing the risk of overheating and maintaining reliable gear performance.

- Sustainability: Gear forging aligns with the sustainability goals of the electric vehicle industry. Forging is a resource-efficient manufacturing process that minimizes material waste compared to other production methods. The high material utilization and recyclability of forged gears contribute to reducing environmental impact, making it an eco-friendly choice for gear production in electric vehicles.

Gear forging technology is continually advancing to meet the unique challenges of high torque transmission in electric vehicles. The superior strength, weight optimization, compact design, noise reduction, efficiency, and thermal management capabilities of forged gears make them a reliable and efficient solution for electric vehicle gear systems. As the electric vehicle market expands, gear forging will continue to play a critical role in enabling the widespread adoption of electric mobility.