Gear hobbing is a widely used and highly effective gear manufacturing process that allows for the production of high-precision gears with excellent quality and efficiency. This article delves into the details of gear hobbing, highlighting its advantages, process steps, and its significance in various industries.

1.Understanding Gear Hobbing:

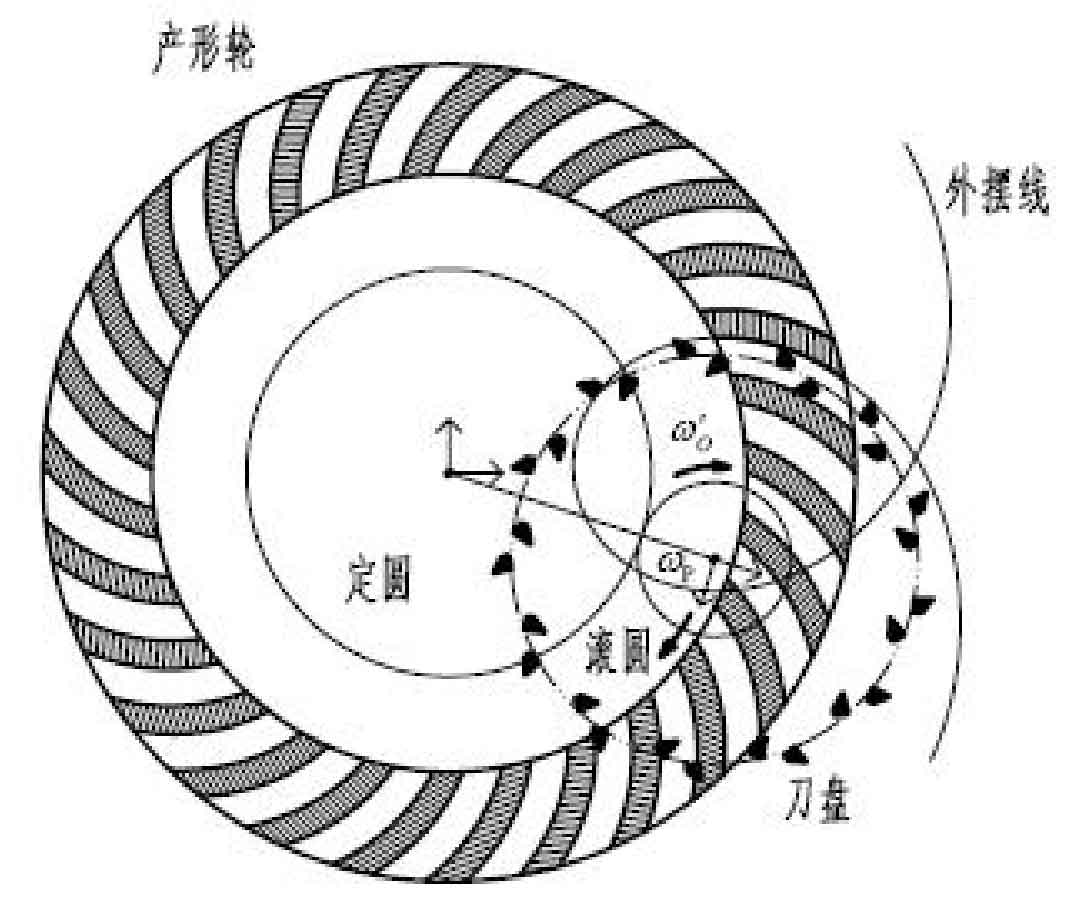

Gear hobbing is a machining process that utilizes a special cutting tool called a hob to produce gears. The hob features a series of teeth that progressively cut into the workpiece to create the desired gear profile. This process is suitable for manufacturing various types of gears, including spur gears, helical gears, and worm gears.

3.Advantages of Gear Hobbing:

Gear hobbing offers several advantages over other gear manufacturing methods:

- Precision: Gear hobbing allows for high accuracy and repeatability, ensuring precise gear tooth profiles and correct dimensions.

- Efficiency: The process is efficient, as multiple gear teeth are cut simultaneously in a single pass, reducing machining time and increasing productivity.

- Versatility: Gear hobbing can produce a wide range of gear types and sizes, making it a versatile manufacturing process.

- Cost-effectiveness: With the ability to produce gears in large quantities, gear hobbing offers cost advantages for high-volume production.

3.Gear Hobbing Process Steps:

The gear hobbing process typically involves the following steps:

- Setup: Mounting the workpiece and the hob onto the gear hobbing machine, ensuring proper alignment and positioning.

- Cutting: The hob rotates while simultaneously moving axially across the workpiece, gradually cutting the gear teeth.

- Indexing: The workpiece is incrementally rotated to produce the desired number of gear teeth.

- Finishing: Additional operations such as gear deburring, heat treatment, and surface finishing may follow the hobbing process to enhance gear quality and performance.

4.Applications in Various Industries:

Gear hobbing finds extensive use in numerous industries, including automotive, aerospace, industrial machinery, and more. It is employed for the production of gears used in power transmission systems, gearboxes, steering mechanisms, and various mechanical applications where precise gear meshing is crucial.

Gear hobbing is a precise and efficient gear manufacturing process that plays a vital role in producing high-quality gears for diverse industrial applications. With its ability to achieve tight tolerances, high productivity, and versatility, gear hobbing remains a preferred choice for gear manufacturers worldwide. The continued advancements in gear hobbing technology will further enhance the process’s capabilities, allowing for the production of even more complex and reliable gears to meet evolving industry demands.