Abstract

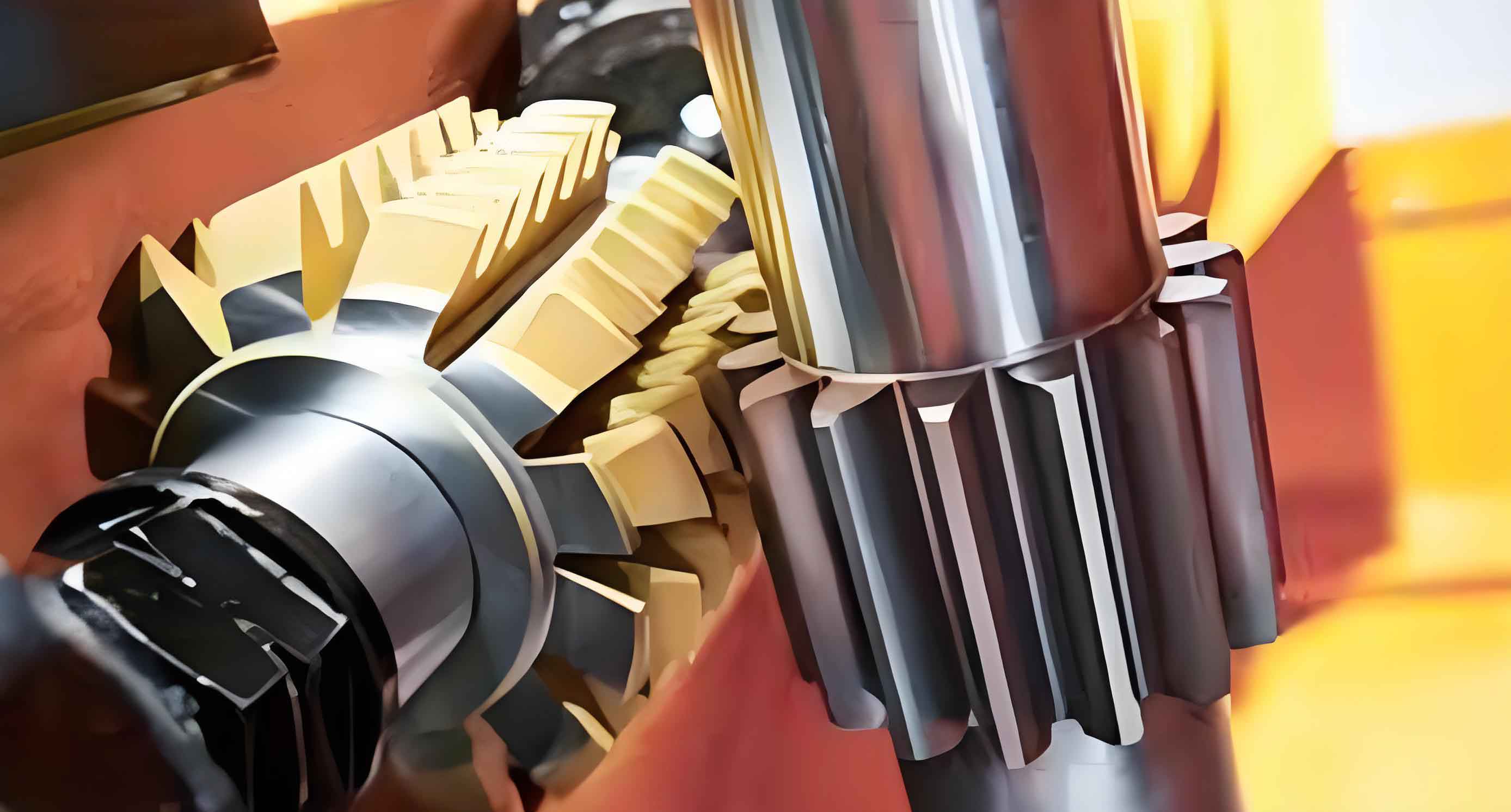

The gear hobbing process of a conjugate pinion for a ruled surface face gear. The conjugate pinion and its manufacturing method are proposed to address the limitation of conjugate relationship between the ruled surface face gear and cylindrical gear, particularly in applications with small transmission ratios. The deviation morphology of the conjugate pinion’s tooth surface compared to a cylindrical gear is obtained. Subsequently, the tooth surface equation of the Archimedean gear hob is derived, and a mathematical model for the cylindrical gear is established based on gear hobbing motion coordinate system and meshing principles. By incorporating radial movement of the hob and additional rotation of the workpiece on the basis of cylindrical gear hobbing motion, the hob’s cutting edge is approximated to the conjugate tooth surface. The additional motion is represented by Taylor polynomials, and the coefficients of the additional NC (Numerical Control) motion polynomials are obtained through iterative solution of a sensitivity matrix equation using singular value decomposition. Finally, the NC-machined tooth surface is achieved. To evaluate the transmission performance of the ruled surface face gear pair, a load tooth contact analysis (LTCA) is conducted and compared with the traditional face gear-cylindrical gear pair.

1. Introduction

Face gears, characterized by their unique tooth geometry and high efficiency in power transmission, have been widely applied in various industries. However, traditional face gears have limitations, especially when paired with cylindrical gears in applications requiring small transmission ratios. The ruled surface face gear, as a new type of face gear, offers potential solutions to these limitations. However, due to the large deviation in tooth shape compared to traditional face gears, it fails to meet the conjugate relationship with cylindrical gears, affecting their meshing performance, transmission accuracy, and service life.

This paper focuses on the development of a conjugate pinion for the ruled surface face gear and its gear hobbing processing method, aiming to replace the traditional face gear-cylindrical gear pair in small transmission ratio applications.

2. Literature Review

Previous research has mainly focused on the study of new tooth profiles for face gears, with little attention to the mating pinions. Studies have been conducted on the load tooth contact performance of ruled surface face gears with straight-tooth cylindrical gears, proving the feasibility of this combination but limited to applications with large transmission ratios, such as helicopter gearboxes. In small transmission ratio applications like fishing reels and instrument mechanisms, the large deviation in tooth shape of the new ruled surface compared to traditional face gears prevents it from meeting the conjugate relationship with straight-tooth cylindrical gears, adversely affecting their meshing performance.

To address this issue, this paper proposes a conjugate pinion and its manufacturing method for the ruled surface face gear under small transmission ratios, aiming to replace the traditional face gear-cylindrical gear pair with the ruled surface face gear pair.

3. Theoretical Basis and Methodology

3.1 Tooth Surface Equation Derivation

The tooth surface equation of the conjugate pinion is derived based on the coordinate transformation and meshing principles between the ruled surface face gear and the conjugate pinion.

Assuming the ruled surface face gear is fixed, and the conjugate pinion rotates around its axis with angular velocity φ2, the relationship between the position vector R2 and normal vector n2 of the tooth surface of the ruled surface face gear and the position vector R1 and normal vector n1 of the tooth surface of the conjugate pinion can be expressed as:

R1(φ2,θc,u)=M12(φ2)R2(θc,u)

n1(φ2,θc,u)=M12(φ2)n2(θc,u)

where M12 is the coordinate transformation matrix.

3.2 Tooth Surface Deviation Analysis

Due to the complexity of the conjugate tooth surface, which varies with tooth width, there are differences between the conjugate tooth surface and the cylindrical gear tooth surface. The tooth surface deviation is analyzed to quantify these differences.

3.3 Numerical Method for NC Machining of Conjugate Tooth Surface

To approximate the theoretical conjugate tooth surface through NC machining, adjustments to the NC axis motion are required. The sensitivity matrix method is employed to solve for the incremental coefficients of the additional motion.

The conjugate pinion tooth surface is represented as a 5×7 grid in the tooth height and tooth width directions, totaling 35 grid points. The theoretical deviation at each point is calculated and written as a column vector δc1 = δi (i = 1, 2, …, q).

4. Hobbing Process of Conjugate Pinion

The gear hobbing process for the conjugate pinion involves using an Archimedean gear hob to cut the tooth surface. Based on the derived tooth surface equation and deviation analysis, the hob’s cutting edge is approximated to the conjugate tooth surface through additional radial movement and rotation of the workpiece.

4.1 Hob Model and Cutting Edge Design

The hob model is designed based on the requirements of the conjugate pinion tooth surface. The cutting edge of the hob is optimized to ensure efficient and accurate cutting of the conjugate tooth surface.

4.2 Hobbing Kinematics and Additional Motion

The gear hobbing kinematics are established considering the rotation of the hob and the workpiece. Additional radial movement and rotation of the workpiece are incorporated to approximate the conjugate tooth surface. The additional motion is represented by Taylor polynomials and iteratively solved using the sensitivity matrix method.

5. Verification and Analysis

5.1 Numerical Example

To verify the correctness of the proposed gear hobbing method for the conjugate pinion, a numerical example is conducted. The basic parameters of the gear pair are shown in Table 1.

| Parameter | Value |

|---|---|

| Face gear modulus | 2 |

| Face gear teeth | 55 |

| Pinion teeth | 17 |

| Transmission ratio | 3.235 |

| Hob diameter | 150 mm |

| Hob helix angle | 30° |

5.2 Position Relationship of Hob Cutting Edge

To ensure that the hob does not produce overcutting during the processing, the position relationship between the hob cutting edge and the conjugate tooth profile as well as the involute tooth profile is analyzed. The position of the hob cutting edge relative to the conjugate tooth profile and the conjugate tooth profile relative to the involute tooth profile at the point of maximum deviation in the machined conjugate tooth surface. It can be observed that the cutting edge of the hob is close to being tangent to each point of the conjugate tooth profile without producing overcutting, indicating the feasibility of the processing motion.

5.3 Load Tooth Contact Analysis

LTCA is conducted to evaluate the transmission performance of the ruled surface face gear pair. The results show that the conjugate pinion can effectively mesh with the ruled surface face gear, demonstrating the feasibility of replacing the traditional face gear-cylindrical gear pair with the ruled surface face gear pair under small transmission ratios.

6. Conclusion

Based on the aforementioned research, the following conclusions are drawn:

- By conjugating a pinion with a ruled surface face gear and comparing its tooth surface with that of a cylindrical gear, it is found that the deviation is mainly distributed at the tooth root and decreases as the transmission ratio increases.

- A corresponding hob model is established, and a processing method for the conjugate pinion tooth surface is proposed. This method can effectively approximate the conjugate tooth surface by adjusting the additional movement of the hob and the additional rotation of the pinion.

- LTCA verifies the feasibility of replacing the traditional face gear pair with the ruled surface face gear pair under small transmission ratios, further expanding the application range of ruled surfaces.