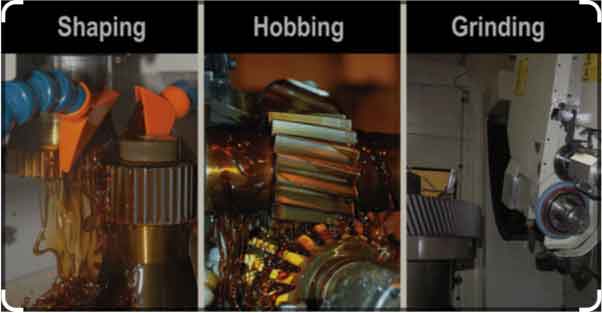

Gear hobbing, gear shaping, and gear grinding are three commonly used methods for manufacturing gears, each offering distinct advantages and suitable for specific applications. Here’s a comparison of these gear manufacturing processes:

1. Gear Hobbing:

- Process: Gear hobbing is a continuous cutting process where a rotating hob cuts gear teeth into the workpiece as it is fed into the hob.

- Suitable Gears: Gear hobbing is versatile and suitable for a wide range of gears, including spur gears, helical gears, worm gears, and splines.

- Precision: Gear hobbing provides good precision and accuracy, making it suitable for many industrial applications.

- Production Volume: Gear hobbing is ideal for medium to high production volumes due to its continuous cutting nature.

- Complexity: It is well-suited for relatively simple gear profiles and can handle more complex profiles with specialized hobs.

- Cost: While the initial setup costs can be higher, the cost per gear reduces significantly for high-volume production runs.

- Surface Finish: Gear hobbing generally produces a good surface finish, but additional finishing operations may be required for high-precision applications.

2. Gear Shaping:

- Process: Gear shaping is a discrete cutting process where a reciprocating cutter (shaper cutter) progressively cuts gear teeth into the workpiece.

- Suitable Gears: Gear shaping is best suited for gears with simple profiles, such as spur gears and internal gears.

- Precision: Gear shaping can achieve higher precision than gear hobbing due to the slow and controlled cutting process.

- Production Volume: Gear shaping is suitable for low to medium production volumes due to the slower cutting process.

- Complexity: It is limited to gears with relatively simple profiles and may not handle very complex geometries.

- Cost: Gear shaping can be cost-effective for low-volume production or when high precision is required for specialized gears.

- Surface Finish: Gear shaping usually provides a smoother surface finish, requiring minimal additional finishing.

3. Gear Grinding:

- Process: Gear grinding is a finishing process where gear teeth are ground to achieve high precision and surface finish.

- Suitable Gears: Gear grinding is commonly used for high-precision gears, especially for hardened gears or those requiring high accuracy.

- Precision: Gear grinding is known for its exceptional precision, achieving tight tolerances and high-quality tooth profiles.

- Production Volume: Gear grinding is more suitable for low to medium production volumes due to the slower grinding process.

- Complexity: It can handle more complex gear profiles and is commonly used for high-precision gears in various industries.

- Cost: Gear grinding is generally more expensive than gear hobbing or gear shaping due to the specialized equipment and precision requirements.

- Surface Finish: Gear grinding produces a superior surface finish, often eliminating the need for additional finishing processes.

Choosing the Right Manufacturing Method:

- Gear Complexity: For complex gear profiles like helical gears or worm gears, gear hobbing or gear grinding may be preferred.

- Precision Requirements: For high-precision gears, especially those with hardened surfaces, gear grinding is the most suitable method.

- Production Volume: Gear hobbing is generally more efficient for high-volume production, while gear shaping and gear grinding are better for low to medium volumes.

- Cost Considerations: Evaluate the overall costs, including setup costs, production volume, and required precision, to determine the most cost-effective method.

In summary, the choice between gear hobbing, gear shaping, and gear grinding depends on the specific gear requirements, precision needs, production volume, and cost considerations. Gear manufacturers often have expertise in selecting the most appropriate method based on the application’s unique parameters.