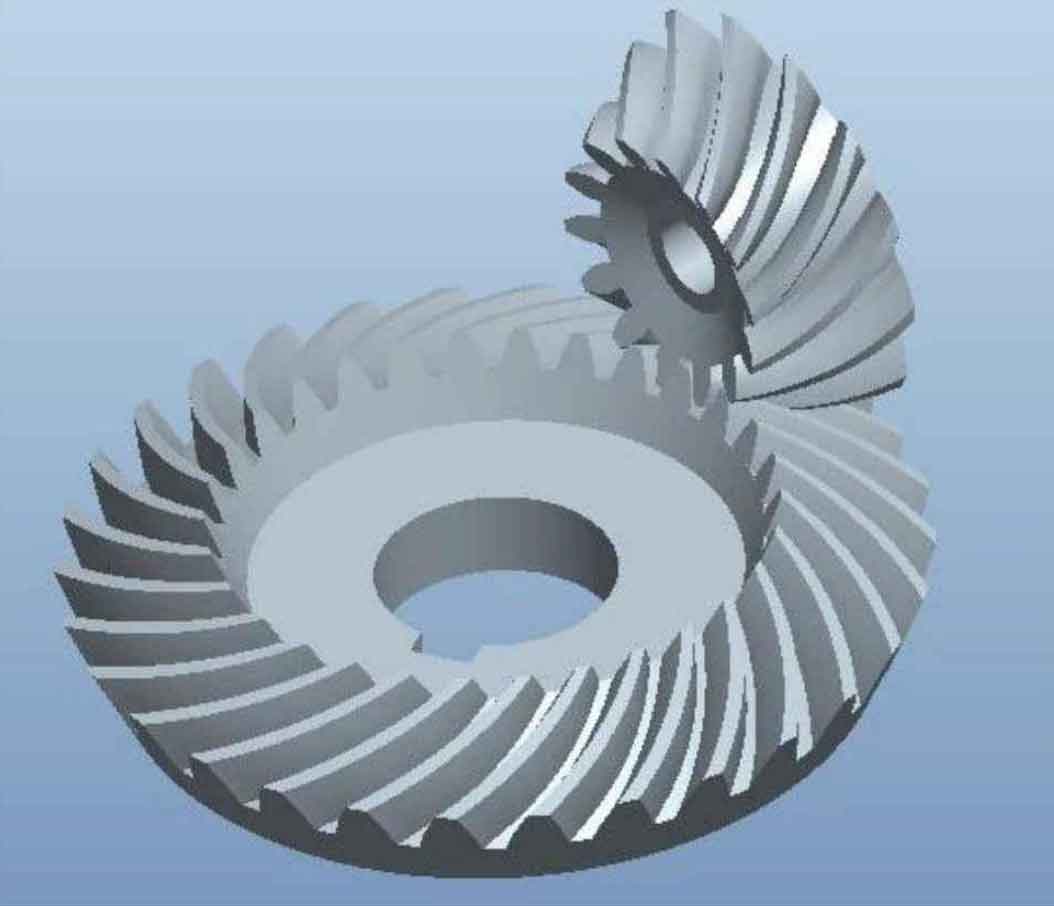

The machining of hypoid gears is realized by the method of generating line gear cutting, that is, the motion conditions of the gear cutting machine are provided by the tooth surface contact line configuration of the gear cutting tool and the movement formed by the meshing surface. The tooth surface machined by this method has no principle error, the required machine tool movement and tool are relatively simple, high efficiency and low cost. Based on this method, a specific processing scheme is developed in this paper. The main work is as follows:

(1) The accuracy of the theory of generating line gear cutting method is analyzed and verified. Because the base cone vertex, surface cone vertex and root cone vertex of hypoid gear do not coincide with each other, the projection of tooth root line and tooth top line on the base plane is not a straight line. Therefore, in order to facilitate subsequent processing, curve fitting is carried out for the cutting area in this paper.

(2) The cutting motion equations are derived for the large and small hypoid wheels respectively. And the following methods are adopted for machining: the machining process of the left tooth surface of the big wheel starts from the root of the small end tooth to the top of the big end tooth, and the machining process of the right tooth surface of the big wheel is the opposite; The left tooth surface of the small wheel is cut from the top of the big end tooth to the end of the small end tooth root cutting; The machining process of the right tooth surface of the small wheel is the opposite.

(3) According to the derived equation, the machining program is compiled. In the software, the three-axis linkage machine tool model and gear blank model are established, and the tool library is established. Then the program is imported into the software for simulation processing, and the correctness of the program is verified.

(4) The machining of gear blank is completed, the machining program is verified by software, and the machining test of gear surface is carried out. The correctness and feasibility of machining hypoid gear by this method are further verified by gear detection.

The hypoid gear processed for gear processing is preliminary processing, and the tool used has not been designed in depth. In the future, the tool should be more perfect, and the related processing technology of hypoid gear tooth surface should be analyzed. The gear material to be processed is nylon, which has low requirements on the stability and strength of the machine tool. Therefore, in the future, we should optimize the processing method and increase the rigidity of the machine tool spindle to realize the processing of metal gear. In the future, it is necessary to further verify the meshing characteristics of the hypoid gear processed by the profile cutting method, and test the parameters of the hypoid gear transmission, so as to further verify the practical applicability of this method.