The gear calculator is a powerful tool that can greatly aid in optimizing the performance and reliability of gears. Here’s how you can use a gear calculator to improve gear performance and reliability:

- Evaluate Gear Parameters: Start by inputting the gear parameters into the gear calculator. These parameters include the number of teeth, gear module, pressure angle, face width, and other relevant specifications. The calculator will use these parameters to perform various calculations and analyses.

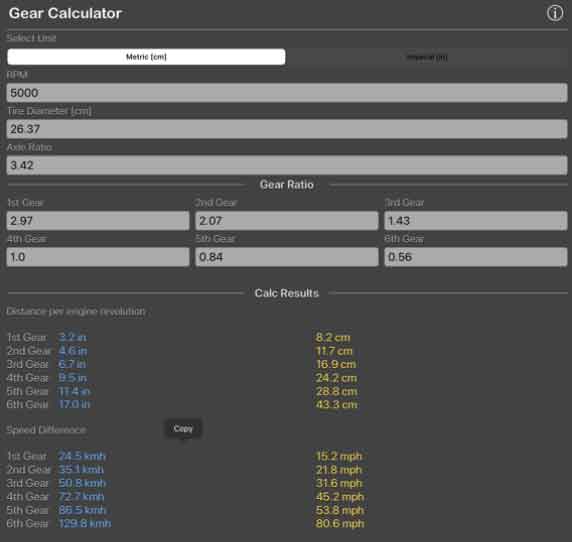

- Calculate Gear Ratios: Use the gear calculator to calculate the gear ratios for your gear system. Gear ratios determine the speed and torque relationship between the driving and driven gears. By adjusting the number of teeth on the gears, you can optimize the gear ratios to achieve the desired output speed and torque.

- Analyze Load Distribution: The gear calculator helps analyze load distribution between gear teeth. It calculates parameters such as contact ratio, contact stress, and tooth load distribution. This analysis allows you to identify areas of high stress concentration and adjust gear parameters, such as pressure angle and tooth profile, to ensure more even load distribution and minimize the risk of tooth failure.

- Optimize Tooth Profiles: The gear calculator generates tooth profiles based on the input parameters. You can visualize the tooth profiles and assess their suitability for your application. By adjusting parameters such as the pressure angle and profile shift, you can optimize the tooth profiles to improve gear meshing, reduce noise, and enhance efficiency.

- Check for Interference and Clearance: The gear calculator helps you check for potential interference or lack of clearance between gear teeth. It calculates the minimum and maximum tooth-to-tooth clearance, ensuring that there is sufficient space for proper gear engagement. This analysis helps prevent tooth interference, minimize noise, and improve the reliability of the gear system.

- Evaluate Efficiency and Power Loss: The gear calculator provides an estimation of gear system efficiency and power loss. It takes into account factors such as tooth profile, friction, lubrication conditions, and mechanical losses. By analyzing the efficiency values, you can identify areas for improvement and make design adjustments to optimize the overall efficiency of the gear system.

- Consider Material Selection: The gear calculator can assist in evaluating the impact of different materials on gear performance. By adjusting the material properties, such as hardness and strength, you can observe changes in factors like contact stress and tooth deflection. This information helps you select the most suitable material for your specific application, ensuring long-term reliability and durability.

- Iterative Design Improvement: Gear design is an iterative process. Use the gear calculator to make adjustments to gear parameters, gear ratios, or tooth profiles based on the analysis results. Iterate on the design, evaluate the impact of changes, and continue refining until you achieve the desired performance and reliability goals.

- Validate Design with Simulation: Many gear calculators offer simulation capabilities to visualize and simulate the behavior of the gear system. Take advantage of this feature to validate your design, observe gear interactions, and ensure that the system operates smoothly. Simulation helps identify any potential issues and fine-tune the design before manufacturing.

- Refer to Industry Standards: When using a gear calculator, refer to industry standards and guidelines to ensure your design adheres to best practices. Consider standards such as AGMA (American Gear Manufacturers Association) or ISO (International Organization for Standardization) for gear design, manufacturing, and quality control. Adhering to standards enhances the performance, reliability, and compatibility of the gear system.

By leveraging the capabilities of a gear calculator, you can optimize gear performance and reliability. The calculator helps analyze load distribution, optimize tooth profiles, check for interference, evaluate efficiency, and iterate on the design to achieve superior performance and reliability in your gear system.