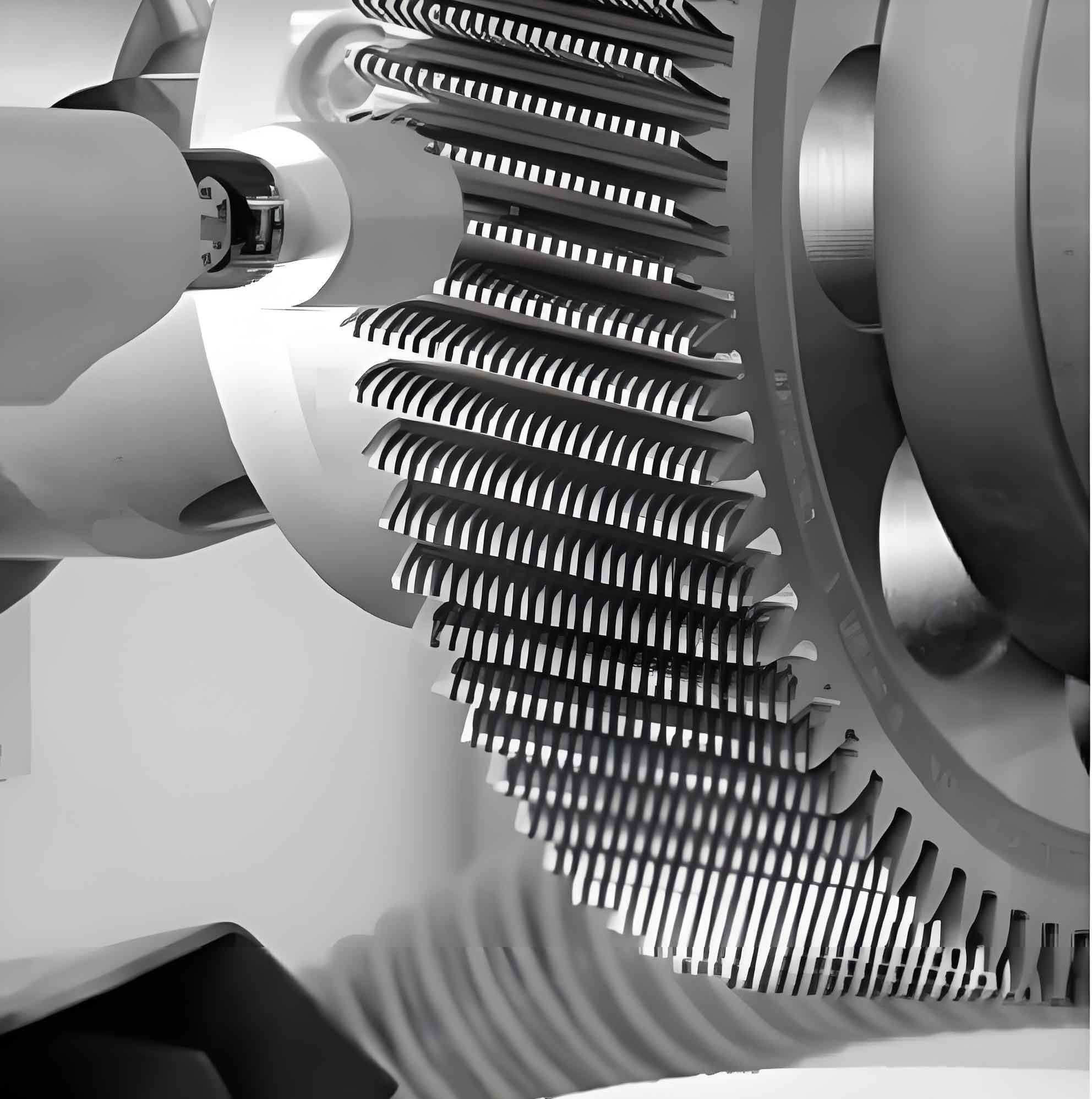

Gear shaving is an economical and highly efficient method for finishing gear teeth. To optimize production planning and enhance efficiency, accurately estimating machining time is essential. Based on different feed directions, gear shaving processes are categorized into four types: axial, diagonal, tangential, and radial. This article focuses on axial and radial gear shaving, the two most common methods.

1. Principles of Gear Shaving

During gear shaving, the primary motion between a disk-type shaving cutter and the workpiece resembles the meshing of crossed helical gears with zero backlash and a small shaft angle (typically 10°–20°). This generates relative sliding along the tooth profile and face width. While detrimental in normal gear operation, this sliding motion enables material removal during gear shaving. The cutting speed \(v\) at the pitch point \(P\) is derived from velocity components:

$$v_{on} = v_o \cos \beta_o, \quad v_{ot} = v_o \sin \beta_o$$

$$v_{wn} = v_w \cos \beta_w, \quad v_{wt} = v_w \sin \beta_w$$

$$v_w = v_o \cos \beta_o / \cos \beta_w$$

$$v = |v_{wt} \pm v_{ot}| = v_o \sin \Sigma / \cos \beta_w$$

$$v_o = \pi d_o n_o / 1000, \quad \Sigma = \beta_w \pm \beta_o$$

where \(\beta_o\) is the cutter’s pitch helix angle (°), \(\beta_w\) is the workpiece’s pitch helix angle (°), \(d_o\) is the cutter’s pitch diameter (mm), \(n_o\) is the cutter’s rotational speed (r/min), and \(\Sigma\) is the shaft angle (°). The sign in \(\Sigma\) depends on helix direction: “+” for same direction, “-” for opposite. Practical gear shaving typically uses a cutting speed of 20–40 m/min.

2. Determining Cutting Parameters for Gear Shaving

Workpiece rotational speed \(n_w\) is calculated as:

$$n_w = n_o z_o / z_w$$

where \(z_o\) and \(z_w\) are cutter and workpiece tooth counts.

Axial Feed Rate (\(f_x\)): Essential for axial gear shaving to cover the entire tooth face, it’s defined as axial movement per workpiece revolution. Selection depends on shaft angle and workpiece teeth:

| Shaft Angle Σ (°) | 17–25 Teeth | 25–40 Teeth | 40–50 Teeth | 50–100 Teeth |

|---|---|---|---|---|

| 7–10 | 0.075–0.10 | 0.10–0.15 | 0.15–0.20 | 0.20–0.25 |

| 10–15 | 0.10–0.15 | 0.15–0.20 | 0.20–0.25 | 0.25–0.30 |

| >15 | 0.15–0.20 | 0.20–0.25 | 0.25–0.30 | 0.30–0.35 |

Axial feed velocity \(v_x\) is:

$$v_x = f_x n_w$$

Radial Feed Rate (\(f_r\)): Both gear shaving methods require radial feed to achieve final tooth thickness. Axial gear shaving uses 4–6 incremental feeds (0.02–0.06 mm each), while radial gear shaving uses lower feed rates due to line contact mechanics.

3. Machining Time Calculation for Axial Gear Shaving

The axial gear shaving cycle includes rapid approach (\(L_s\)), radial feed (\(L_r\)), axial feed (\(L_x\)), dwell return (\(L_m\)), finishing (\(L_f\)), and rapid retract (\(L_b\)). Key distances are:

$$L_r = \Delta W / (2 \sin \alpha_n), \quad L_x = b_w + 2m$$

where \(\Delta W\) is allowance on normal chordal thickness (mm), \(\alpha_n\) is normal pressure angle (°), \(b_w\) is face width (mm), and \(m\) is module.

Total machining time \(t\) comprises:

$$t = t_s + t_r + t_x + t_m + t_f + t_b$$

$$t_s = L_s / v_q, \quad t_r = \sum_{i=1}^{n} L_{ri} / v_r$$

$$t_x = n L_x / v_x, \quad t_m = L_m / v_q$$

$$t_f = N L_x / v_f, \quad t_b = (L_s + L_r – L_{rn}) / v_q$$

Here, \(v_q\) is rapid traverse velocity (mm/min), \(v_f\) is finishing feed velocity (\(\approx \frac{2}{3} v_x\)), \(L_{ri}\) are radial increments (mm), \(L_m\) is return distance (0.02–0.04 mm), \(n\) is radial feed count (4–6), and \(N\) is finishing passes (2–4).

Worked Example: Workpiece: \(m = 2.5\), \(z_w = 23\), \(\alpha_n = 20°\), spur gear, \(b_w = 18\) mm, material 20CrMnTi, hardness ≤217 HBW, allowance \(\Delta W = 0.07\) mm. Cutter: \(z_o = 67\), \(\beta_o = 15°\). Machine: YWA4232.

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| \(n_o\) | 225 r/min | \(n_w\) | 655.43 r/min |

| \(f_x\) | 0.15 mm/r | \(v_x\) | 100 mm/min |

| \(v_f\) | 60 mm/min | \(L_r\) | 0.102 mm |

| \(L_x\) | 23 mm | \(L_s\) | 0.2 mm |

| \(L_m\) | 0.02 mm | Radial feeds (\(n\)) | 4 |

| Finishing passes (\(N\)) | 2 | \(v_r\) | 3.75 mm/min |

Axial gear shaving time breakdown:

| Phase | Time (min) |

|---|---|

| Rapid Approach (\(t_s\)) | 0.05 |

| Radial Feed (\(t_r\)) | 0.03 |

| Axial Feed (\(t_x\)) | 0.92 |

| Dwell Return (\(t_m\)) | 0.005 |

| Finishing (\(t_f\)) | 0.77 |

| Rapid Retract (\(t_b\)) | 0.08 |

| Total Time (\(t\)) | 1.86 |

4. Machining Time Calculation for Radial Gear Shaving

Radial gear shaving uses a modified cutter profile enabling full tooth contact without axial feed. Its cycle comprises rapid approach (\(L_s\)), radial feed (\(L_r\)), pause (\(t_p\)), dwell return (\(L_m\)), and rapid retract (\(L_b\)). Machining time is:

$$t = t_s + t_r + t_p + t_m + t_b$$

$$t_p = t_{p1} + t_{p2} + \cdots + t_{pn} + t_{pf}$$

Worked Example (Same Workpiece): Machine: YWA4232 with radial shaving cutter (\(z_o = 67\), \(\beta_o = 15°\)). Parameters: \(n_o = 225\) r/min, \(v_q = 3.75\) mm/min, \(v_r = 0.67\) mm/min, pause time per feed = 4 s (0.067 min), \(L_s = 0.2\) mm, \(L_m = 0.02\) mm.

Radial gear shaving time breakdown:

| Phase | Time (min) |

|---|---|

| Rapid Approach (\(t_s\)) | 0.05 |

| Radial Feed (\(t_r\)) | 0.15 |

| Pause (\(t_p\)) | 0.13 |

| Dwell Return (\(t_m\)) | 0.005 |

| Rapid Retract (\(t_b\)) | 0.08 |

| Total Time (\(t\)) | 0.42 |

5. Efficiency Comparison and Conclusion

Radial gear shaving reduces machining time by 77% compared to axial gear shaving in this case study. The elimination of time-consuming axial feed cycles—despite slower radial feed rates—drives this efficiency gain. While axial gear shaving spends >90% of its cycle on axial movements, radial gear shaving concentrates on controlled radial infeed with brief pauses. For high-volume production, radial gear shaving is preferable where equipment and tooling permit. Both methods remain vital for precision gear manufacturing, with gear shaving consistently proving its value in cost-effective finishing.