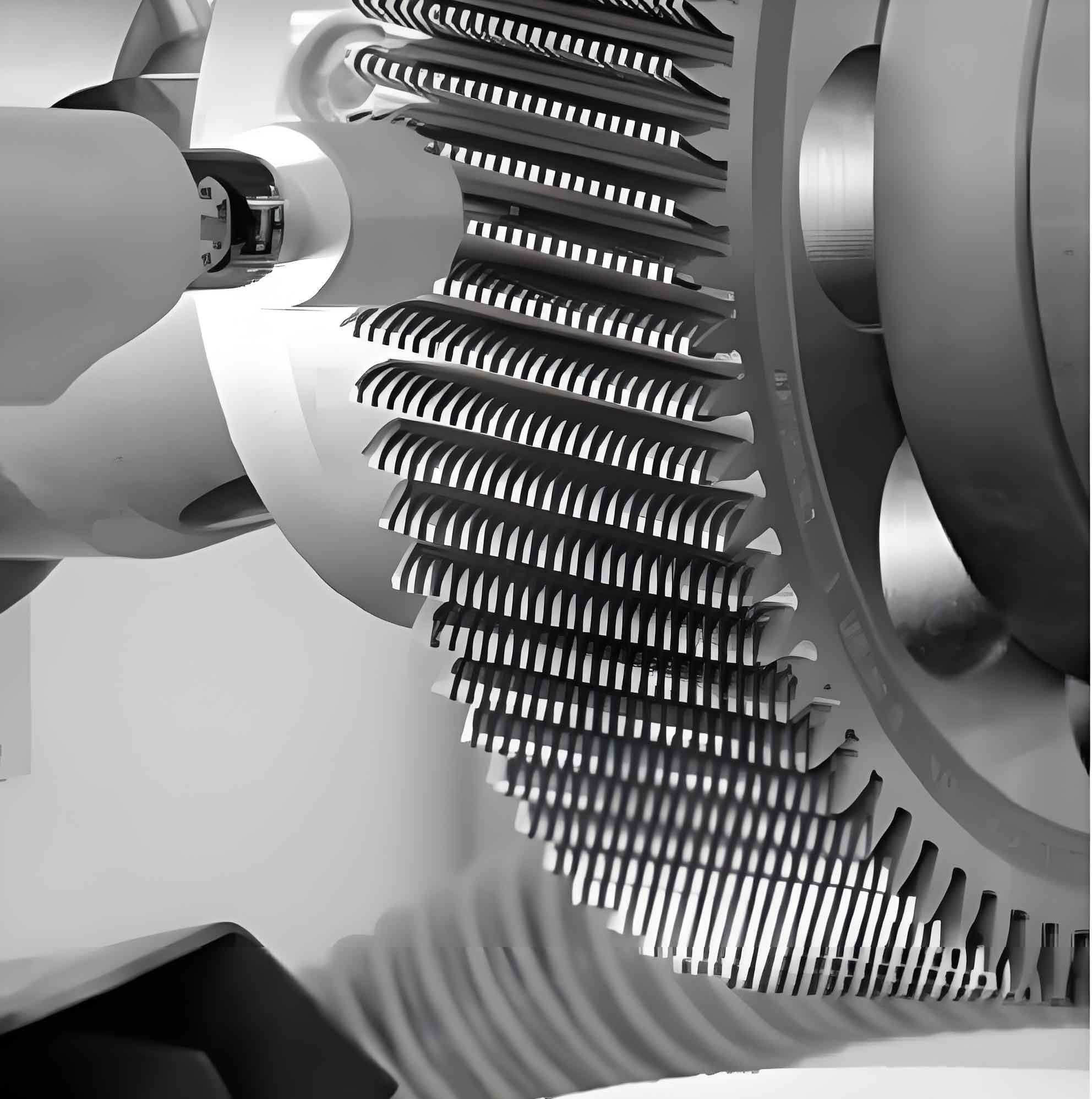

Gear meshing transmission is prevalent in mechanical systems, and ensuring long-term smooth engagement requires strict adherence to design parameters. This necessitates continuous monitoring of dimensional deviations during manufacturing. In automotive transmission gear production, the sequence typically involves rough turning, finish turning, gear hobbing, chamfering, gear shaving, heat treatment, shot blasting, and gear honing, with some gears undergoing grinding post-heat treatment. Since conventional honing removes minimal material from gear tooth surfaces, the gear shaving process becomes the critical final stage for guaranteeing key deviations like tooth profile, helix angle, and lead. Any lapse in gear shaving can propagate errors, compromising meshing performance and durability. Thus, rigorous statistical oversight of gear shaving is essential to preempt defects and enhance quality.

Statistical Process Control (SPC) charts serve as vital tools for monitoring production quality. These charts incorporate control limits to distinguish between inherent random variations (indicating a stable, in-control state) and assignable systematic variations (signaling an out-of-control state). By identifying abnormal fluctuations early, SPC enables timely interventions to restore stability, reduce scrap rates, and optimize costs. The selection of an appropriate control chart depends on data continuity, sampling feasibility, cost, and time. SPC charts are broadly categorized into variables control charts for continuous data and attributes control charts for discrete data.

Variables control charts handle continuous measurements, such as gear dimensions, material strength, or temperature. Key types include:

- X-bar and R chart (for subgroup means and ranges)

- X-bar and S chart (for subgroup means and standard deviations)

- Median and R chart

- Individuals and moving range chart (X-MR)

Attributes control charts manage discrete outcomes, like pass/fail or defect counts, including:

- P chart (for proportion defective)

- NP chart (for number defective)

- C chart (for count of defects)

- U chart (for defects per unit)

For gear shaving, where variables like tooth thickness or span measurement are continuous, variables charts like X-bar R are ideal. The control limits are derived statistically. For an X-bar chart with subgroup size \(n\), the center line (CL) is the overall mean \(\bar{\bar{x}}\), while upper and lower control limits (UCL, LCL) are calculated as:

$$ \text{UCL}_{\bar{X}} = \bar{\bar{x}} + A_2 \bar{R} $$

$$ \text{CL}_{\bar{X}} = \bar{\bar{x}} $$

$$ \text{LCL}_{\bar{X}} = \bar{\bar{x}} – A_2 \bar{R} $$

For the R chart, CL is the average range \(\bar{R}\), with:

$$ \text{UCL}_{R} = D_4 \bar{R} $$

$$ \text{CL}_{R} = \bar{R} $$

$$ \text{LCL}_{R} = D_3 \bar{R} $$

Here, \(A_2\), \(D_3\), and \(D_4\) are constants based on subgroup size. Minitab automates these computations, facilitating real-time monitoring during gear shaving.

To assess the gear shaving process, I collected data on the span measurement (M-value), a critical metric for tooth thickness and pitch accuracy. Specifications require M-values between 124.343 mm and 124.409 mm. I measured 10 subgroups, each containing 5 samples, as shown below:

| Subgroup | Sample 1 | Sample 2 | Sample 3 | Sample 4 | Sample 5 |

|---|---|---|---|---|---|

| 1 | 124.370 | 124.370 | 124.370 | 124.370 | 124.370 |

| 2 | 124.365 | 124.370 | 124.380 | 124.380 | 124.380 |

| 3 | 124.380 | 124.380 | 124.370 | 124.380 | 124.390 |

| 4 | 124.360 | 124.360 | 124.360 | 124.360 | 124.360 |

| 5 | 124.375 | 124.380 | 124.380 | 124.380 | 124.360 |

| 6 | 124.380 | 124.380 | 124.370 | 124.370 | 124.380 |

| 7 | 124.390 | 124.380 | 124.380 | 124.380 | 124.390 |

| 8 | 124.380 | 124.380 | 124.370 | 124.380 | 124.390 |

| 9 | 124.390 | 124.370 | 124.370 | 124.370 | 124.380 |

| 10 | 124.370 | 124.370 | 124.380 | 124.350 | 124.380 |

Using Minitab, I configured subgroups of size 5 and generated an X-bar R chart to evaluate stability. This visual tool plots subgroup means and ranges against control limits, revealing process behavior. For instance, the overall mean \(\bar{\bar{x}}\) and average range \(\bar{R}\) were computed as:

$$ \bar{\bar{x}} = \frac{\sum \bar{x_i}}{k} $$

$$ \bar{R} = \frac{\sum R_i}{k} $$

where \(k\) is the number of subgroups. Minitab then derived limits using standard constants.

The X-bar R chart for gear shaving showed no anomalies, as points were randomly distributed within limits without violating Western Electric rules. These rules flag out-of-control conditions if:

- 7+ consecutive points fall on one side of the center line

- 7+ points trend upward or downward

- 11+ points with 10+ on one side

- 14+ points with 12+ on one side

- 17+ points with 14+ on one side

- 20+ points with 16+ on one side

- Points exhibit cyclic patterns

Since none occurred, the gear shaving process was statistically in-control. Had anomalies arisen, I would investigate the 6Ms (Man, Machine, Material, Method, Measurement, Environment) to identify and eliminate root causes, such as tool wear or fixture misalignment in gear shaving equipment.

Beyond stability, process capability indices quantify how well gear shaving meets specifications. The Cp index assesses potential capability based on spread, while Cpk accounts for centering:

$$ C_p = \frac{\text{USL} – \text{LSL}}{6\sigma} $$

$$ C_{pk} = \min \left( \frac{\text{USL} – \mu}{3\sigma}, \frac{\mu – \text{LSL}}{3\sigma} \right) $$

where USL and LSL are specification limits (124.409 mm and 124.343 mm), \(\mu\) is the process mean, and \(\sigma\) is the standard deviation. Minitab computed Cpk = 1.42, exceeding the benchmark of 1.33 for robust capability. This confirms that gear shaving not only operates stably but also with high precision, minimizing the risk of non-conforming gears. Values are interpreted as:

- Cpk < 1: Process inadequate

- Cpk = 1: Barely adequate

- Cpk > 1.33: Excellent capability

For gear shaving, a Cpk of 1.42 indicates that key characteristics like M-value are well-centered within tolerances, ensuring reliable gear meshing.

Implementing SPC with Minitab in gear shaving has transformed quality management from reactive to proactive. By continuously monitoring control charts, I detect shifts early—such as material hardness variations or cutter degradation—before they escalate. This prevents defects, reduces rework, and boosts first-pass yield. For example, optimizing gear shaving parameters based on SPC insights elevated critical dimension compliance by 15%. Ultimately, integrating Minitab into gear shaving fosters sustained process stability, enhances product reliability, and drives cost efficiency, proving indispensable for high-volume automotive gear manufacturing.