1. Division of nodes on tooth surface

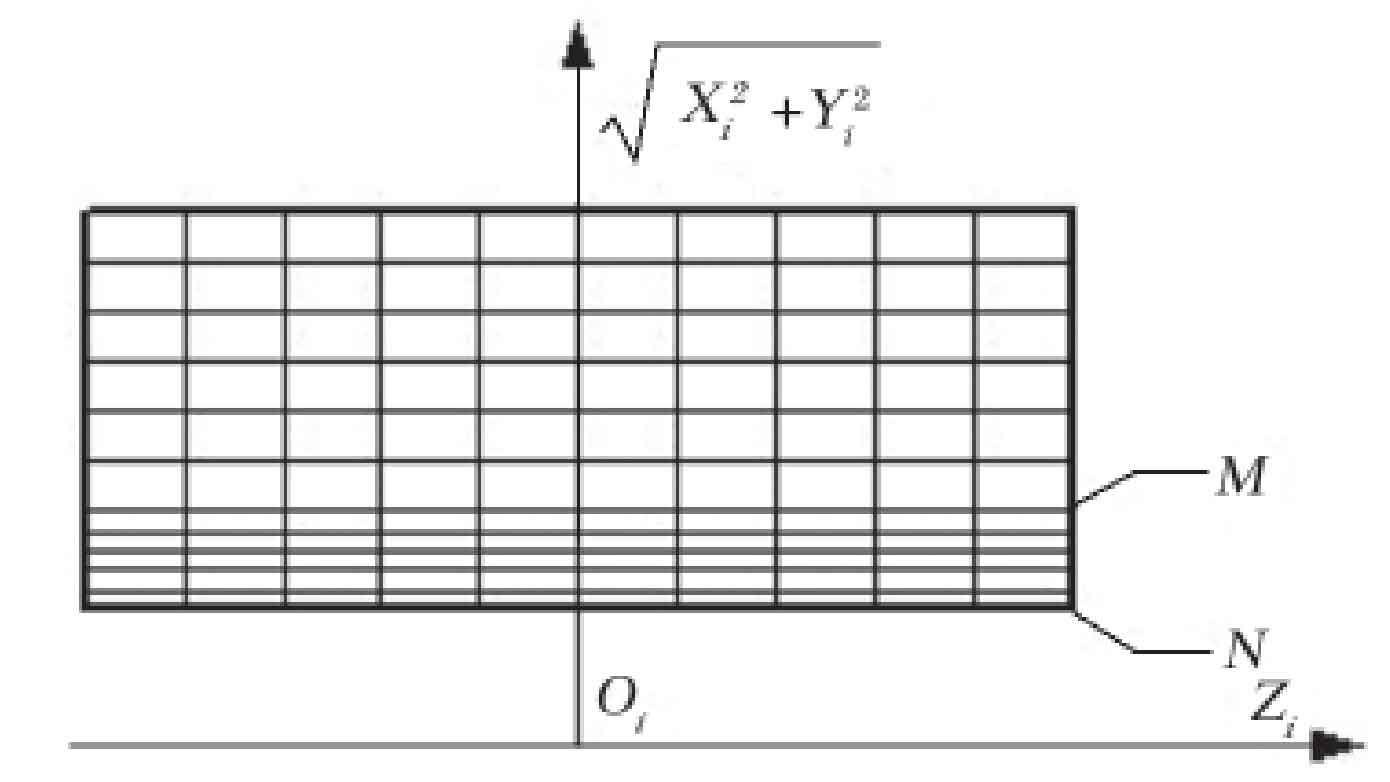

The axis plane coordinate system is established based on the arc tooth surface gear coordinate system Si, as shown in Figure 1. The abscissa is the coordinate axis Zi of the coordinate system Si, which coincides with the circular rotation axis of the arc tooth surface gear wheel, the ordinate is, and the coordinate origin is at the midpoint of the tooth width on the axis Zi. The nodes are evenly divided along the direction of tooth length and tooth height on the shaft plane. When dividing the nodes, the whole gear tooth is divided into two parts. The working surface of the gear tooth is from the top of the gear tooth to the m point, and Mn is the transition surface of the tooth root. Properly encrypt the transition surface of the tooth root.

2. Determination of node coordinates on tooth surface

Tooth surface equation of arc tooth surface gear. Let the coordinates of the j-th node on the tooth surface in the coordinate system Si be:

The coordinates of the corresponding grid nodes on the axis plane are:

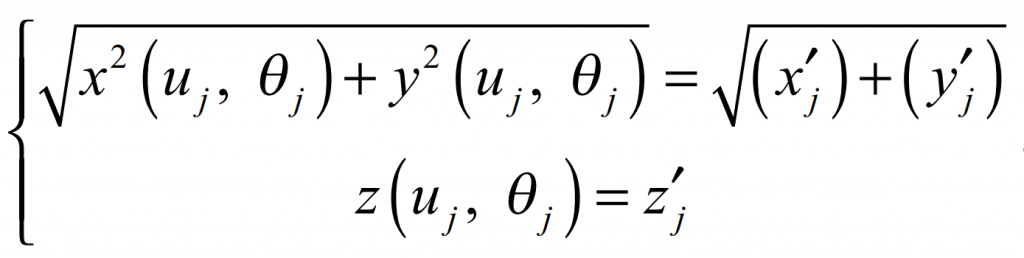

The corresponding relationship between the mesh nodes on the tooth surface and the nodes on the shaft plane is as follows:

The formula is a system of two-dimensional nonlinear equations to solve the parameters UJ θ J can determine the coordinates of the j-th node on the tooth surface, and similarly divide the node on the other side of the tooth surface.

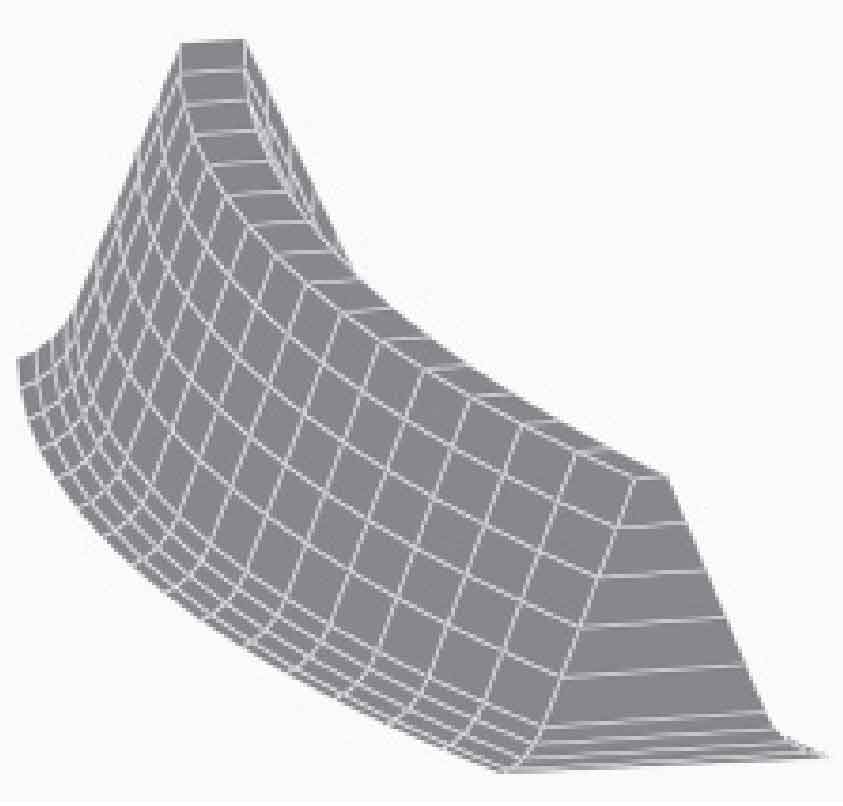

The tooth model is shown in Figure 2. The tooth is divided into 16 nodes on the tooth surface along the tooth length direction, 8 elements on the tooth surface along the tooth height direction, and the transition curve is divided into 6 nodes on the tooth surface. Using FORTRAN language, we have compiled relevant programs to generate the precise coordinates of a single tooth of the arc tooth surface gear, and imported the node coordinates of the two tooth surfaces of the arc tooth surface gear in CATIA environment to obtain a point cloud of the tooth.

In the modeling, the subtraction of Boolean operation is adopted, that is, the cogging model is subtracted from the wheel blank model to form the arc tooth surface gear. Therefore, it is necessary to treat the point cloud of gear teeth as the point cloud of tooth slots. After the point cloud on one side of the tooth rotates by 2 π / Z1 around the Z axis (z1 is the number of teeth of the arc tooth surface gear), a tooth becomes a tooth slot to form the point cloud of the tooth slot.