Abstract

Spiral bevel gears are extensively utilized due to their smooth transmission, low noise, and high load capacity. The manufacturing accuracy of spiral bevel gears plays a crucial role in determining the precision of mechanical products. Therefore, enhancing the machining accuracy of spiral bevel gear processing machines is a vital task. This paper focuses on the research of a full Computer Numerical Control (CNC) spiral bevel gear milling machine, determining a real-time error compensation scheme and system, with a triaxial micro milling machine serving as the test platform.

1. Introduction

1.1 Background and Significance of the Research

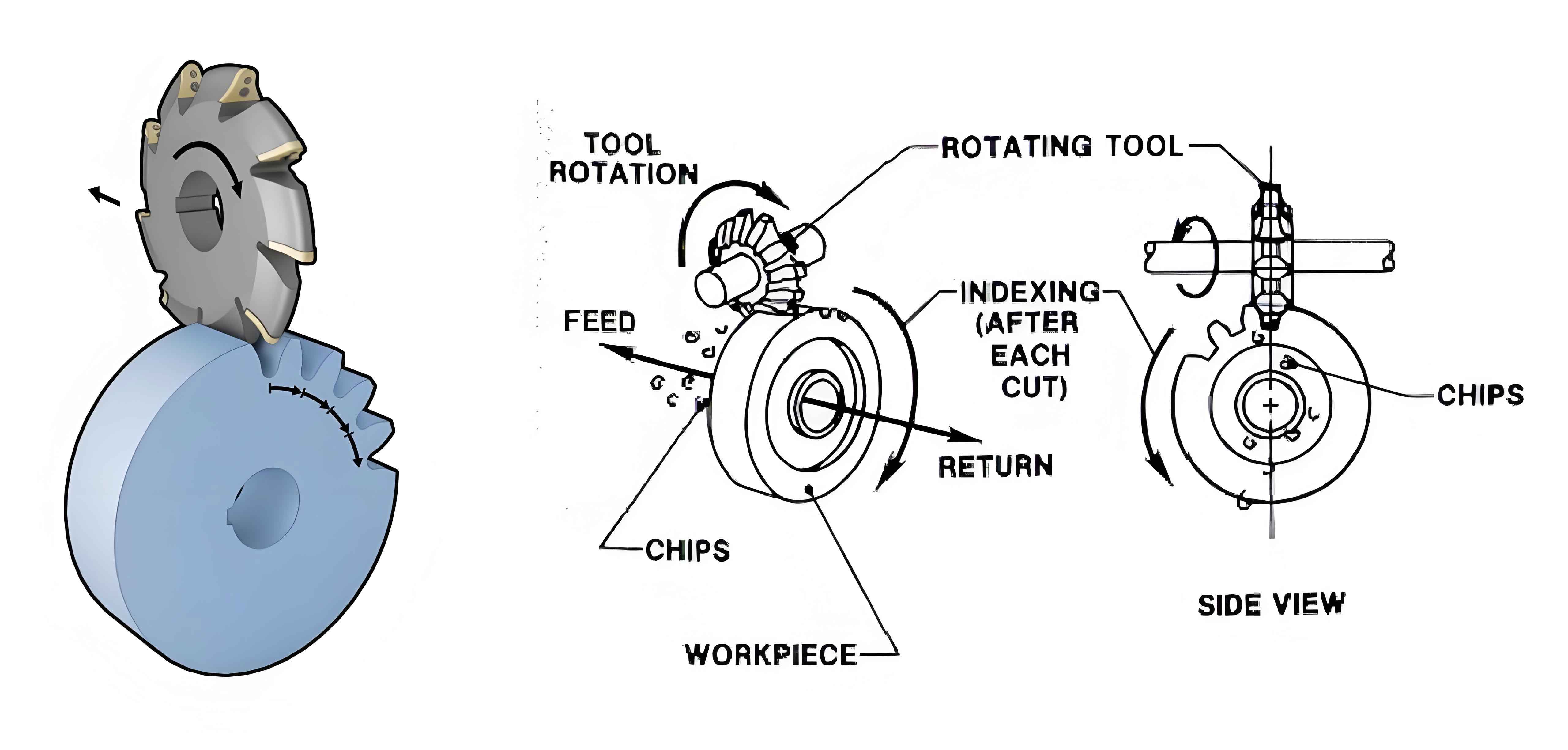

Spiral bevel gears are critical components in various industries such as aviation, automotive, and defense. However, there is a significant gap between domestic and foreign spiral bevel gear milling machines, particularly in manufacturing accuracy. To address this, research on geometric error compensation technology for CNC spiral bevel gear milling machines is conducted to improve machining accuracy.

1.2 Development Overview of Spiral Bevel Gear Machining Machines

Globally, three companies dominate the market for spiral bevel gear machining machines and technologies: Oerlikon (Switzerland), Klingenberg (Germany), and Gleason (USA). These companies have achieved a monopoly worldwide. In contrast, domestic spiral bevel gear milling machines lag behind in both theory and practice, especially in manufacturing accuracy and the widespread use of mechanical machine tools, which can lead to geometric errors, thermal errors, and control errors, reducing processing accuracy.

1.3 Research Status of Geometric Error Detection and Compensation Technologies

1.3.1 Research Status of Geometric Error Detection for CNC Machines

Insertions can be included here to illustrate the current research status, but due to formatting limitations, they are omitted in text form.

1.3.2 Research Status of Geometric Error Compensation Technology for CNC Machines

Similarly, research on geometric error compensation technology for CNC machines has been advancing globally, focusing on improving machining accuracy through various methods.

2. Analysis of Geometric Error Sources and Compensation Elements

2.1 Determination of Geometric Error Sources

The primary error source in CNC spiral bevel gear milling machines is static geometric error. Various geometric error elements need to be compensated, including positioning errors, straightness errors, flatness errors, and angular errors.

2.2 Establishment of an Error Element Table

Based on the analysis of geometric error sources, an error element table for milling machines is established, listing all error elements that require compensation and their corresponding parameters.

Table 2.2 Milling Machine Error Element Table

| Error Element | Description | Parameter |

|---|---|---|

| Positioning Error | Deviation of the actual position from the theoretical position | ΔP |

| Straightness Error | Deviation of a straight line from its ideal straightness | ΔS |

| Flatness Error | Deviation of a plane from its ideal flatness | ΔF |

| Angular Error | Deviation of an angle from its ideal value | Δθ |

2.3 Establishment of a Mathematical Model for Error Compensation

Based on the error element table, a mathematical model for error compensation is established, taking into account various geometric error elements and their interactions.

3. Design of the Real-time Error Compensation System

3.1 Selection of the Compensation System

A closed-loop feedback compensation system is chosen for its ability to provide real-time error detection and correction. The feedback interruption strategy is selected as the error compensation implementation strategy.

3.2 System Architecture

The real-time error compensation system is designed using an “IPC+PMC” architecture, ensuring good real-time performance, responsiveness, and safety. The system includes hardware and software components, with a human-machine interface and a database for storing data.

3.3 Compensation Process

The compensation process involves detecting geometric error elements using sensors, transmitting sample data to the main control center, calculating error values based on the error model, and sending compensation signals to the PMC controller to correct the NC instructions.

4. Simulation and Verification of the Error Compensation System

4.1 Simulation of the Error Compensation System

A modular simulation approach is adopted, where each component is simulated separately and then assembled into the system. Positioning errors are chosen as the test objects for simulation.

4.2 Simulation Results

Without error compensation, the actual position does not match the theoretical position. However, with error compensation, the actual position aligns with the theoretical position, proving the effectiveness of the compensation system.

5. Experimental Verification and Function Testing

5.1 Experimental Setup

The experimental setup includes a main control center and a triaxial micro milling machine as the test platform. The error real-time compensation system is built and configured on this platform.

5.2 Function Testing and Results

Various error compensation functions are tested, including pitch error compensation, reverse clearance error compensation, straightness error compensation, flatness error compensation, and cooperative error compensation. The results show that each function is effective, with each coordinate point following the third-order spline interpolation algorithm.

6. Conclusion and Future Work

This paper focuses on the research of geometric error compensation technology for CNC spiral bevel gear milling machines. By analyzing error sources, establishing error element tables, and designing a mathematical model for error compensation, a real-time error compensation system is developed and verified through simulation and experiments. The results show that the compensation system is effective in improving machining accuracy.

Future work could include further optimization of the error compensation model, improvement of the real-time performance of the compensation system, and application of the technology to other types of machining machines.