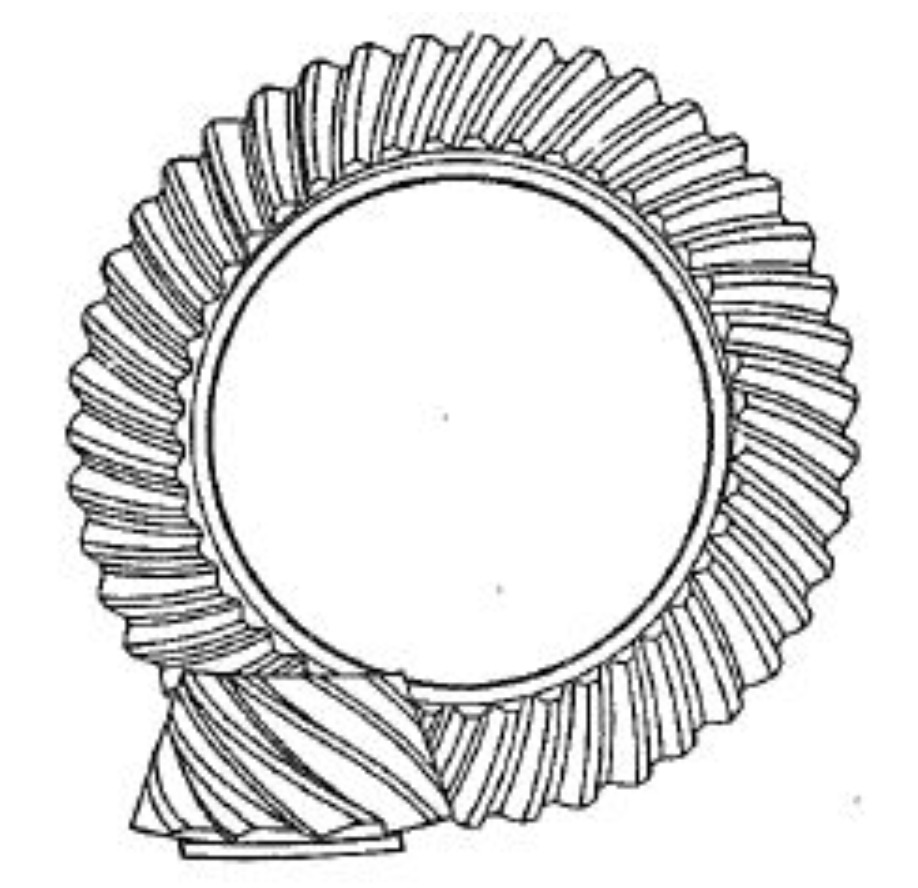

Hypoid gears are critical components in automotive drivetrains, particularly for rear-wheel-drive vehicles, where their contact zone quality directly impacts NVH performance. This paper presents a systematic methodology for controlling post-heat-treatment contact zone deviations through cutting compensation strategies.

1. Thermal Distortion Characteristics

The first-order relative tooth surface error model effectively captures heat treatment-induced distortions in hypoid gears. The distortion relationship between driving (pinion) and driven (gear) components is expressed as:

$$

\begin{cases}

\alpha = \Delta\alpha_z – \Delta\alpha_b \\

\beta = \Delta\beta_z – \Delta\beta_b

\end{cases}

$$

where $\alpha$ and $\beta$ represent relative pressure angle and spiral angle errors, respectively. Experimental data from 27 gear pairs reveals consistent distortion patterns:

| Surface | Pressure Angle Change (arcmin) | Spiral Angle Variation (arcmin) |

|---|---|---|

| Pinion Convex | +5.0 ± 0.3 | -3.2 ± 0.5 |

| Gear Concave | +7.1 ± 0.4 | -7.5 ± 1.2 |

2. Contact Zone Migration Mechanism

The relative spiral angle error ($\beta$) predominantly governs contact zone displacement in hypoid gears. The directional shift can be quantified through gap differential analysis:

$$

\begin{cases}

\Delta L_H = \frac{1}{5}\sum_{i=1}^{5} L_H(i,9) \\

\Delta L_T = \frac{1}{5}\sum_{i=1}^{5} L_T(i,1)

\end{cases}

$$

where $L_H$ and $L_T$ represent relative clearances at heel and toe ends. Experimental validation demonstrates:

| β (arcmin) | Contact Zone Position | Length Coverage |

|---|---|---|

| 4.0 | Mid-to-heel | 35-45% |

| 6.0 | Central | 40-50% |

| 8.0 | Mid-to-toe | 45-55% |

3. Cutting Compensation Strategy

The predictive compensation model for hypoid gear cutting parameters is developed as:

$$

\Delta\beta_{comp} = \frac{\beta_{post-HT} – \beta_{target}}{1 – e^{-k(T_c – T_0)}}

$$

where $T_c$ represents carburizing temperature and $k$ is material-dependent compensation factor. Implementation results show:

| Parameter | Pre-HT Error | Post-HT Error | Improvement |

|---|---|---|---|

| Spiral Angle (arcmin) | -8.2 ± 1.5 | -5.3 ± 0.6 | 67% |

| Pressure Angle (arcmin) | +6.8 ± 0.9 | +1.2 ± 0.3 | 82% |

4. Quality Validation Protocol

The post-compensation verification process for hypoid gears incorporates:

$$

Q_{index} = \frac{1}{n}\sum_{i=1}^{n} \left( w_1|\alpha_i| + w_2|\beta_i| \right)

$$

where $w_1$ and $w_2$ are weighting factors (0.4 and 0.6 respectively). Production batch analysis (n=360) demonstrates:

| Batch Segment | Qindex (Before) | Qindex (After) |

|---|---|---|

| Initial 5% | 8.7 ± 1.2 | 2.1 ± 0.4 |

| Middle 90% | 9.1 ± 0.9 | 1.8 ± 0.3 |

| Final 5% | 8.9 ± 1.1 | 2.0 ± 0.5 |

This comprehensive approach enables effective control of hypoid gear contact zone characteristics post-heat-treatment, achieving consistent NVH performance while maintaining production efficiency. The methodology demonstrates particular effectiveness in automotive applications where precise torque transmission and noise reduction are critical.