According to the differences of loading methods, structural types and working modes of gear test devices, they can be divided into two categories: 1) running gear test devices; 2) Non running gear test device.

The running testing machine can obtain the fatigue performance of the gear when the gear is in the working state. The running tester can monitor the influence of real-time working state and real-time load on the gear. However, the running test machine has high requirements for the environment, which also makes it more difficult to control the fatigue form of the running test machine.

The test is carried out on the non running unidirectional high frequency resonance bending fatigue testing machine. The specific model is the general plg200 high frequency fatigue testing machine, as shown in the figure. Its characteristic is that when the actual gear pair is engaged, the load generated on the two tooth surfaces is applied by the action of the indenter. The output vibration waveform has small distortion, large working frequency range (up to 500Hz), easy to control, and improves the accuracy of the test. At the same time, in order to eliminate the influence of external miscellaneous environment on the test accuracy, the test must be carried out at room temperature.

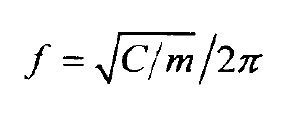

Its natural frequency is shown in the formula:

Where: C – total stiffness of mechanical resonance system, N / M; M – mass of mechanical resonance system, kg.