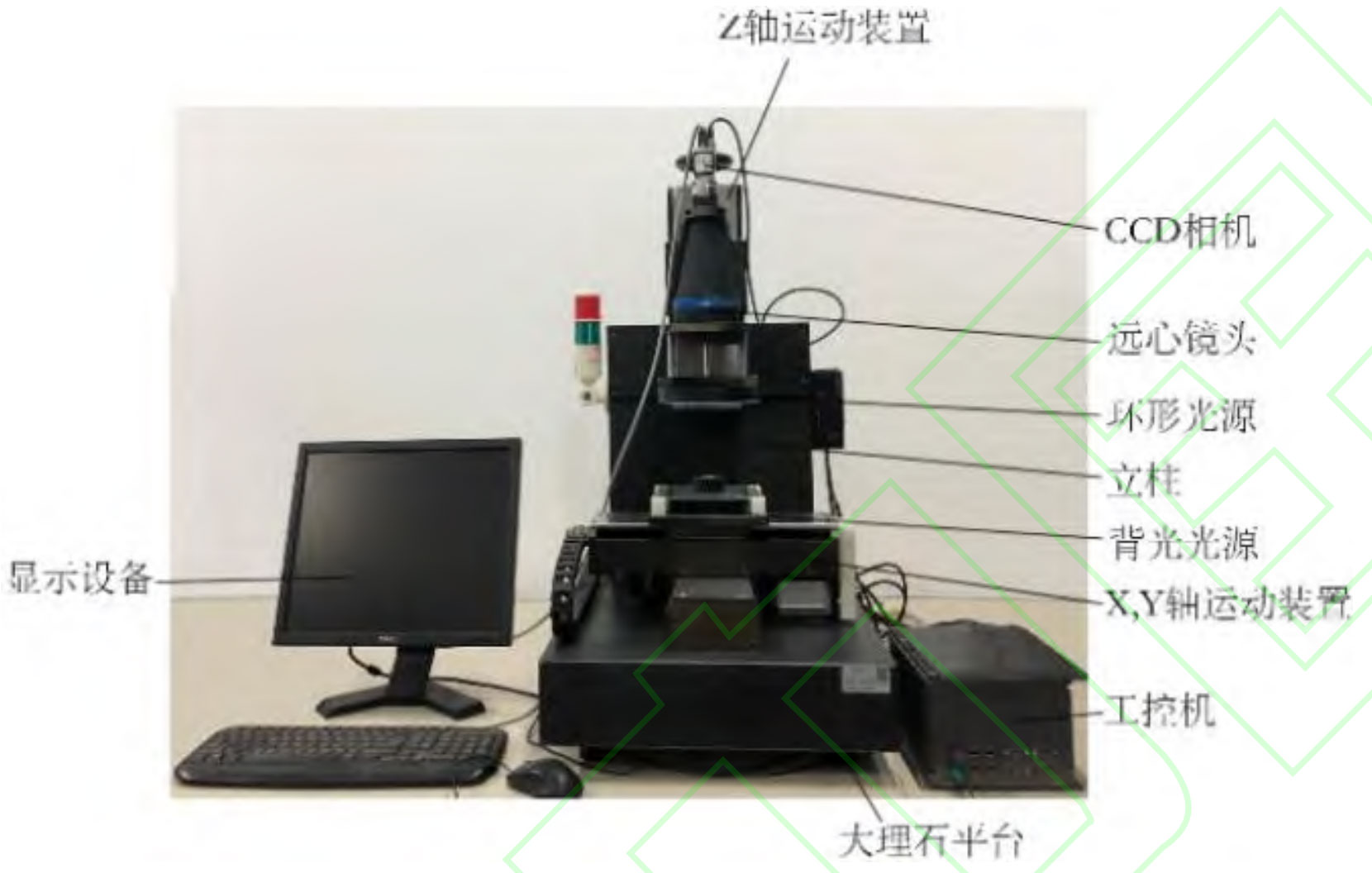

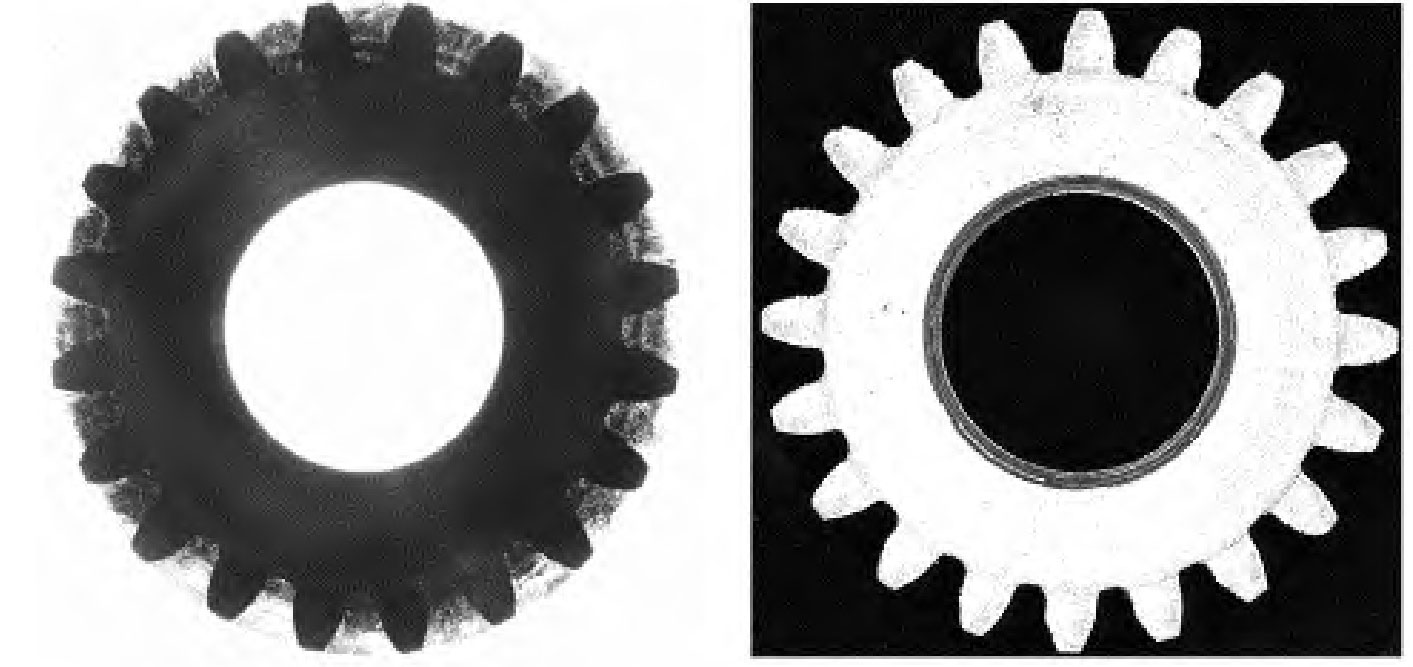

The overall hardware of the helical gear detection system mainly consists of an industrial camera, a telecentric lens, a light source, and a motion device. The combination of circular light source and backlight light source can be selected as the light source to maximize the contrast of the image. The impact of using different light sources on image quality is shown in Figure 1. The lens is an OPTO Engineering TC12064 telecentric lens with a maximum distortion of 0.04%. The high depth of field characteristic of telecentric lenses can reduce image distortion during imaging and improve the detection accuracy of the system. The camera uses Basler’s acA1600 black and white industrial camera, with a resolution of 2MP and a frame rate of 20fps.

Place the tested helical gear on the testing platform, and the industrial camera will convert the obtained helical gear image through an image acquisition card and transmit it to the industrial computer. After preprocessing the helical gear image, the noise in the image is eliminated, its subpixel edge contour is extracted, the image is fitted, and its parameters are detected. Detect the rotation angle of the tooth top area in the side image of the helical gear to convert the helix angle, classify the rotation direction of the helical gear through the side image, and display the detection results, as shown in Figure 2.