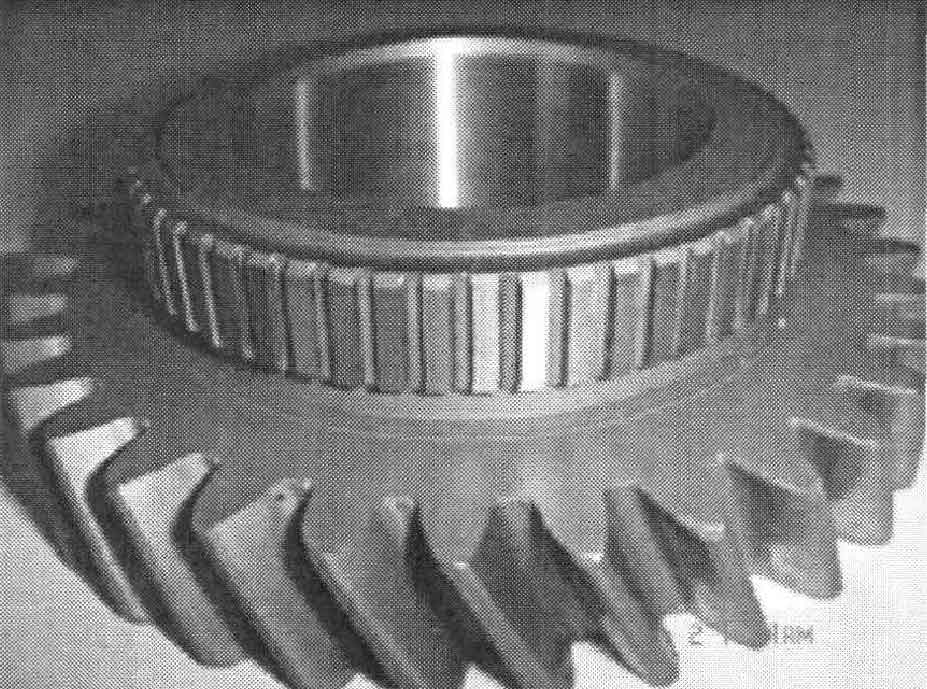

At present, most electric vehicle OEMs use motor+gearbox+rear axle (as shown in the figure) instead of motor+rear axle, which not only reduces the weight of the whole vehicle by 100kg, but also greatly reduces the cost. Because of the irreplaceability of the gearbox, how to improve the vibration and noise characteristics of the gear pair in the gearbox during transmission, make its transmission more stable, and improve the strength of the gear to increase its life, has become the key for engineers in various enterprises to break through the industry bottleneck and seize the market opportunity. In addition, it is pointed out in the Gear Manual that the shape and design of the gear body are the key factors affecting the vibration noise and service life of the gear. However, most scholars at home and abroad lack systematic research on gear modification, especially on the advantages and disadvantages of different gear modification methods and their combinations. As a result, many enterprises often modify gears based on experience, which results in that sometimes the gear with experience modification has higher vibration noise, worse strength and lower life than the gear without modification.

In view of the appeal, the mechanism of vibration and noise of electric vehicle reduction gearbox and helical gear pair was studied in depth, the influence of different gear modification methods and their combinations on the vibration and noise, strength life, and transmission stability of helical gear pair was explored, and a novel process for determining the optimized gear modification scheme was proposed. That is, first of all, the premise of the top modification and long modification of the gear is defined according to the applicable working conditions. Then, the modification scheme is preliminarily drawn up after considering the selection of large and small modification gears, the selection of tooth profile and tooth direction, different modification methods and composite modification. Then, KISSsoft software was used to analyze the meshing performance, and the modified gears with excellent performance were selected and imported into LMS Virtual Lab Motion software for dynamic simulation and re optimization. Then, combined with dynamic excitation, shell flexibility, modal structure response, etc., acoustic analysis was carried out in LMS Virtual Lab Acoustic software to determine the optimal scheme. Finally, through the combination of simulation and test, we can understand the reason why the vibration and noise characteristics and service life of helical gear pair of an enterprise decline after experience modification

Interpretation.

(1) This paper introduces the development history and research status of helical gear vibration and noise mechanism, prediction, evaluation and analysis means, classification, origin, development process and research status of gear modification technology, the extensive application and research status of helical gear finite element simulation, and proposes to modify the helical gear pair of electric vehicle reducer to achieve the purpose of vibration reduction and noise reduction.

(2) The mechanism of vibration and noise of reduction gearbox and helical gear pair of electric vehicle is investigated. The nonlinear vibration mathematical model of helical gear pair of primary reduction gearbox is established, and the gear vibration excitation is deeply analyzed.

(3) Firstly, the helical gear modification technology is introduced in detail, including types, applicable working conditions and three elements. Then, taking the helical gear pair of an electric vehicle gearbox as the research object and formulating the modification scheme, the influence of helical gear parameters such as helix angle, pressure angle and tooth width on its meshing performance is explored in KISSsoft software, and the modification scheme is preliminarily screened based on transmission error and Hertz contact stress optimization. Finally, the meshing performance of some optimized modification schemes, such as oil film thickness, flash temperature and tooth surface contact temperature, is analyzed in depth.

(4) On the basis of the preliminary optimization modification scheme, the nonlinear multi-body dynamics simulation of the helical gear pair of an electric vehicle gearbox was completed. On the basis of model verification, the influence of helical gear pair parameters (such as helix angle, pressure angle, backlash, etc.) and gear optimization modification on its own dynamic excitation (including time-varying meshing stiffness and time-varying meshing force) was explored, The second optimal modification scheme based on reducing time-varying meshing stiffness and time-varying meshing force is summarized.

(5) The modal analysis is briefly introduced, the natural modal calculation and vibration mode analysis of the shell are completed, and the acoustic simulation process is described in detail. Based on the verification of the acoustic model, the acoustic characteristics of all secondary optimization modification schemes for the helical gear pair of an electric vehicle gearbox are compared and analyzed.

(6) On the basis of the meshing contact simulation and multi-body dynamics simulation of the two pairs of helical gear pairs before and after the empirical modification of an enterprise, combined with the contact spot and noise bench test, while verifying the simulation results, according to the internal dynamic excitation of the helical gear and the change of the Hertz contact stress on the tooth surface, the reason why the vibration and noise characteristics and the service life of the helical gear pair decline after the traditional empirical modification is explained.