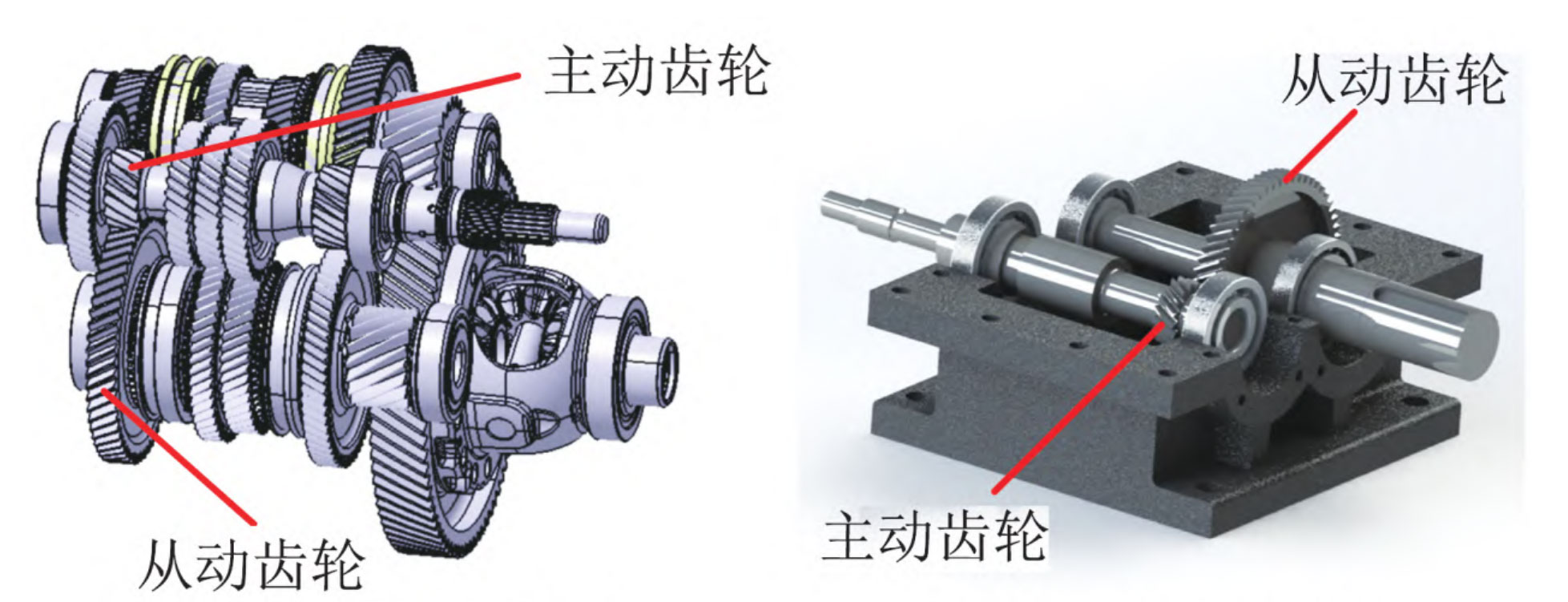

The first gear helical gear pair determines the maximum torque that an automotive automatic transmission can withstand, and it has a significant impact on the overall design of the transmission. Therefore, analyzing, calculating, and testing the first gear helical gear pair is of great significance. The helical gear transmission system and the first gear helical gearbox model are shown in the figure.

The first gear helical gearbox includes an upper and lower box body and a meshing helical gear pair. The Deep Groove Ball Bearing with high transmission efficiency and accuracy is selected according to the load that the helical gear box bearing needs to bear, and the angular contact ball bearing that can bear large axial load is used at the output end. The lubrication method is oil injection lubrication by the upper tank cover fuel injection pump. Control the oil temperature at 80 ℃ through a temperature cycling control system. The parameters of the helical gear pair are shown in the table.

| Parameter | Driving gear | Driven gear |

| Number of teeth | 17 | 60 |

| Tooth width/mm | 19.8 | 16.9 |

| Coefficient of displacement | 0.3721 | -0.0994 |

| Modulus/mm | 2.1 | 2.1 |

| Pressure angle/(°) | 17.5 | 17.5 |

| Helix angle/(°) | 29 | 29 |

| Center distance/mm | 93 | 93 |

| Density/(kg · m^-3) | 7840 | 7840 |

| Elastic modulus/GPa | 210 | 210 |

| Poisson’s ratio | 0.3 | 0.3 |