With the rapid growth of China’s automobile consumption market, China has become a big automobile production and marketing country. Therefore, people’s requirements for automobile comfort and reliability are further improved. High performance, high efficiency and low cost have become the urgent needs of China’s automobile industry for parts manufacturing. Drive axle largely determines the power transmission performance of the vehicle. In recent years, the research on the influence of high-performance drive axle on automobile has become a hot spot.

As early as the 1960s and 1970s, domestic and foreign countries have begun to study the impact of automobile drive axle on the overall performance of the vehicle. At that time, the vibration of the whole vehicle can be controlled by controlling the vibration of the drive axle. In recent years, the research on the impact of the drive axle on the overall performance of the vehicle has been more in-depth, in order to improve the vehicle NVH (noise, vibration and acoustic vibration roughness, noise, vibration) In order to improve the performance of the car and shorten the design cycle, the structure and quality of the drive axle are optimized.

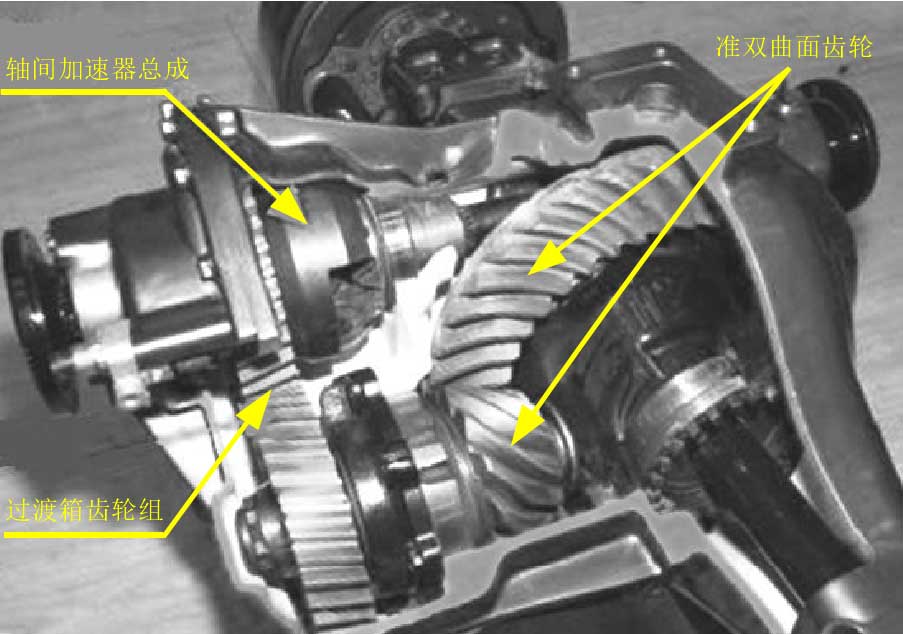

Hypoid gear is widely used in automobile drive axle (Fig. 1). Its strength and dynamic performance have great influence on vehicle reliability and comfort. Fig. 1 shows hypoid gear used in automobile drive axle.