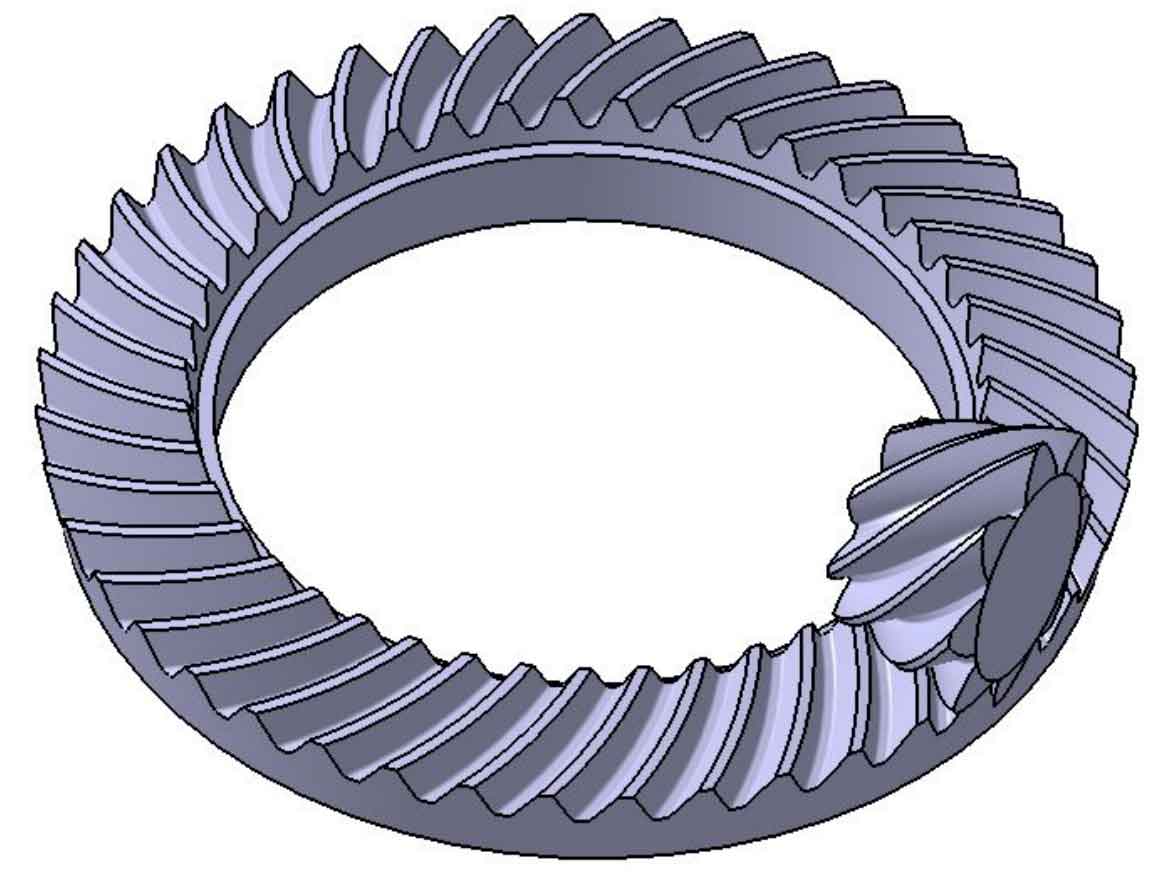

As early as 1820, many mathematicians have put forward the concept of hypoid gear. Its essence is a space geometry problem. After many years of research, mathematicians have established a geometric model according to the space meshing theory and vector operation rules. However, due to the limitations of the technical conditions at that time and the lack of precision processing equipment, the hypoid gear has been in the theoretical stage. With the emergence of CNC machine tools and the progress of machining technology, hypoid gears can be changed from theory to reality, and then applied to various equipment.

In 1910, Paul bttcher, a German, published a report on the machining technology of hypoid gears. The content of the report was very extensive and systematically described the design principle and machining technology of hypoid gears. In this report, he proposed for the first time the technology of machining hypoid gears with disk milling cutters.

In 1913, James, an engineer of Gleason company in the United States Gleason designed the first hypoid gear cutting machine tool and successfully produced hypoid gears. Subsequently, Gleason machine tool was widely promoted in the world. On this basis, all countries designed their own machining machines, and hypoid gears began to be widely used.

The history of hypoid gears is intertwined with the broader development of gear technology and the automotive industry, marking significant advancements in engineering and mechanical design over the years.

Early Developments

- Antiquity and Middle Ages: While the basic concept of gears dates back to the Antikythera mechanism of ancient Greece and the water clocks of medieval Islam, hypoid gears as we know them did not exist in these early periods. These civilizations developed various types of gears, including spur and worm gears, laying the groundwork for future mechanical innovations.

- 19th Century: The foundation for modern hypoid gear technology began to take shape with the industrial revolution and the advent of more complex machinery. However, it was not until the late 19th century that significant progress was made in the theoretical understanding and practical application of gear designs, including bevel and spiral gears, which are closely related to hypoid gears.

The Rise of Hypoid Gears

- Early 20th Century: Hypoid gears emerged as a distinct and innovative gear type in the early 20th century, primarily driven by the automotive industry’s need for more efficient and compact differential gears. The offset design of hypoid gears, which allows the drive shaft to be lower than the axle shafts, was particularly beneficial for improving vehicle stability and interior space.

- 1920s and 1930s: The use of hypoid gears became more widespread in automotive rear axles during this period. One of the key advantages of hypoid gearsets was their ability to transmit power smoothly and quietly compared to the previously used straight-cut bevel gears. This period marked significant advancements in the manufacturing and precision engineering of hypoid gears, largely driven by automotive manufacturers like General Motors and Ford.

Technological Advances and Wider Adoption

- Mid-20th Century: The mid-20th century saw continued improvements in the design, manufacturing, and materials used for hypoid gears. The adoption of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies further enhanced the precision and efficiency of hypoid gear production. These advancements allowed for wider adoption of hypoid gears in various industries beyond automotive, including aerospace, marine, and heavy machinery.

- Late 20th Century to Present: The development of new materials, lubricants, and heat treatment processes has continued to improve the performance, durability, and efficiency of hypoid gears. Today, hypoid gears are a critical component in many high-performance and heavy-duty applications, benefiting from ongoing research and development efforts aimed at optimizing their design and operational characteristics.

Throughout their history, hypoid gears have evolved from a novel solution for automotive differentials to a widely used component in many industrial applications. This evolution reflects broader trends in engineering and technology, including the push for more compact, efficient, and durable mechanical systems.