Hot precision forging of spur gear is a precision forming method developed from hot die forging technology. It is mainly suitable for the forming of gears with large tooth width and large modulus. It has the advantages of small forming load, simple forming method and high material utilization rate, but the forming quality and surface quality are poor and the forming accuracy is low, It is often used for precision manufacturing before machining or for gear manufacturing with low precision requirements such as agricultural machinery.

The hot forging cold forging composite forming process of spur gear is a forming process combining hot precision forging and cold precision forging. It gives full play to the advantages of good metal plasticity, small forming load, easy filling, high forming precision and high surface quality during cold precision forging. However, several processes need to be added for cold forging after hot forging, resulting in low material utilization and production efficiency, In addition, the forming load is large during cold forging, and it is difficult to fill the top of the upper and lower teeth. After forming, the gear accuracy is even worse at din10 ~ 12 level, and the subsequent machining of the tooth surface still needs to be added. Therefore, the compound forming process of hot forging and cold forging of spur gears is only suitable for the compound forming of small module and small tooth width gears. There are still some difficulties in the forming of large module spur gears, and the practical popularization still needs further research.

The hot forging cold extrusion compound forming process of spur gear is a compound forming process proposed on the basis of summarizing the hot forging cold forging compound forming process of spur gear. After hot forging, the gear is finished by cold extrusion process. Tian Fuxiang of Qingdao University of technology first put forward the hot forging cold extrusion compound forming process of spur gear, and designed a precision hot forging die without flash. After a series of process experiments, it is pointed out that the main reasons affecting the precision of the extruded gear are the manufacturing precision and shaping allowance of the extrusion tooth profile die. Zuo bin, from Beijing University of science and technology, established the gear hot forging model by theoretical analysis and finite element simulation, proposed the control method of spur gear hot precision forging tooth profile accuracy, established the cold extrusion model based on hot forging, analyzed the metal flow law and gear accuracy control method in the cold extrusion process, and designed the three-stage cold extrusion die, The process experiment results show that the planetary gear formed by hot forging and cold extrusion has high tooth profile accuracy and good surface quality.

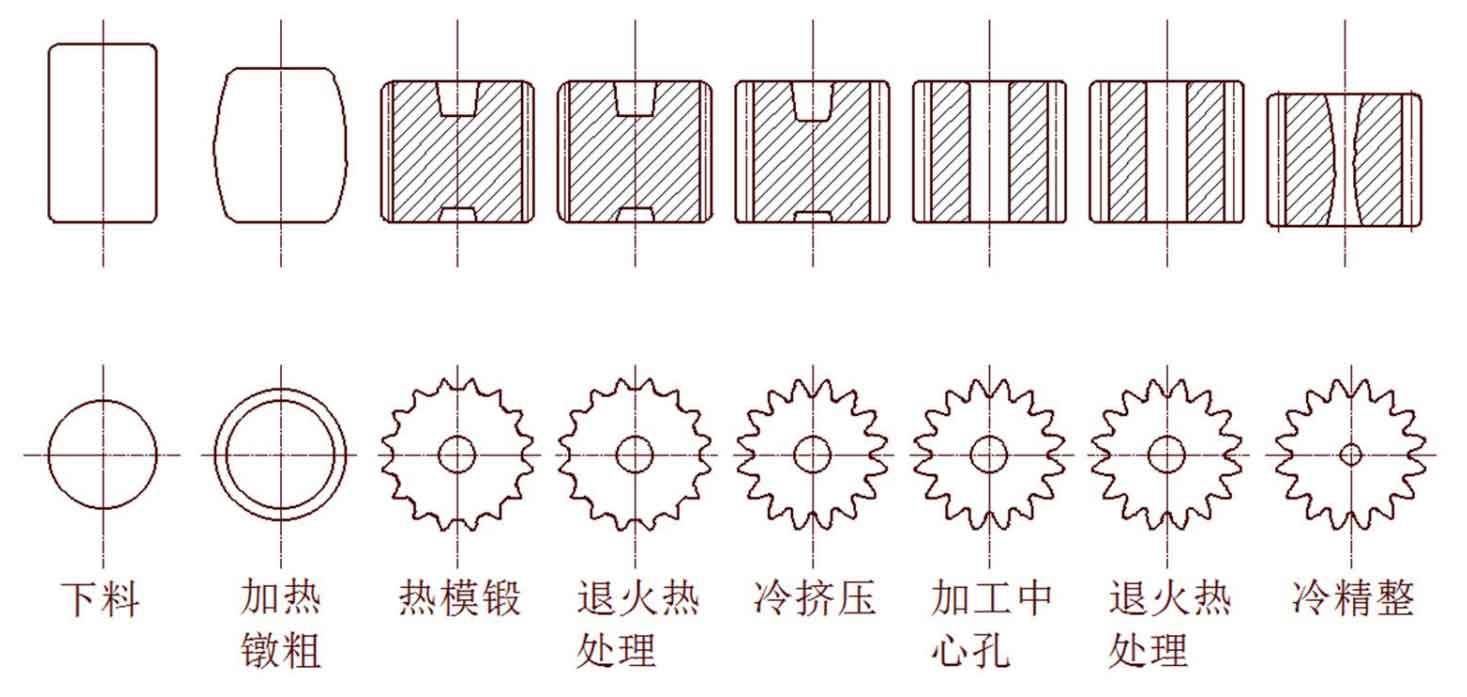

When the hot forging cold extrusion compound forming process is used to process large-scale spur gears, the service life of the cold extrusion tooth profile die is low, which is caused by the large deviation of the shaping amount of each tooth of the gear after hot forging, and the tooth orientation accuracy after hot forging has a great impact on the cold extrusion finishing effect. To solve this problem, Bian Yi and others of Beijing Electromechanical Research Institute put forward the composite forming process of hot forging, cold extrusion and cold finishing, as shown in the schematic diagram of the process route. The three-step forming reasonably distributes the deformation and improves the service life of the cold extrusion tooth concave die. Increasing the cold finishing process can effectively improve the accuracy of the formed gear, and the formed tooth surface can meet the accuracy requirements of shaving, Only a small amount of machining is required for the gear end face and inner hole. Although the process can improve the gear forming accuracy, there are many processes, which affect the production efficiency.