The gear calculator plays a crucial role in optimizing gear system performance by providing valuable insights and facilitating design improvements. Here’s how a gear calculator can help unlock efficiency in gear systems:

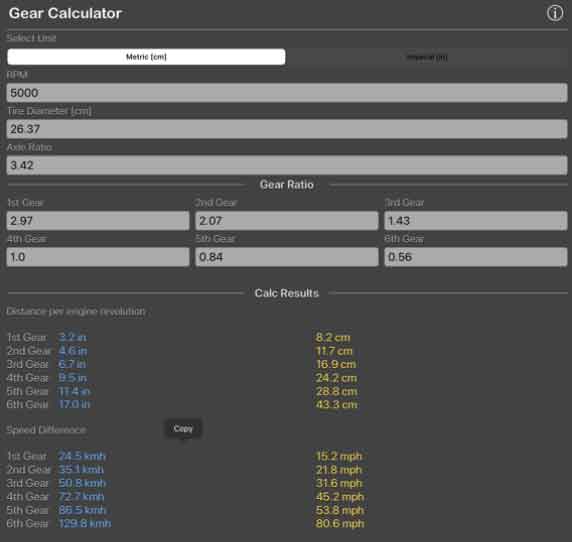

- Accurate Gear Ratio Selection: A gear calculator allows you to input the desired input and output speeds and calculate the required gear ratio. By optimizing the gear ratio, you can achieve the desired speed reduction or increase while minimizing power losses. The calculator helps you find the optimal gear ratio that balances speed requirements with efficiency.

- Optimal Gear Tooth Profile: The gear calculator assists in determining the appropriate tooth profile parameters such as addendum, dedendum, and tooth thickness. By inputting the desired gear module or diametral pitch, the calculator helps you achieve the optimal tooth profile for the specific application. An optimized tooth profile ensures proper load distribution, reduces stress concentrations, and minimizes noise and vibration.

- Load Distribution Analysis: Gear calculators often provide load distribution analysis, allowing you to assess how the load is distributed across the gear teeth. This analysis helps identify potential areas of high stress concentration or uneven load sharing. By adjusting gear parameters, such as the number of teeth or gear dimensions, you can optimize load distribution for improved gear performance and durability.

- Efficiency Calculations: Gear calculators enable you to estimate the efficiency of the gear system. By considering factors such as gear type, tooth profile, lubrication conditions, and load characteristics, the calculator can provide an estimate of the system’s efficiency. This information helps in evaluating the impact of different design choices and optimizing the gear system for higher efficiency.

- Power Loss Analysis: Gear calculators can estimate power losses within the gear system. By considering factors such as friction, tooth engagement, and lubrication efficiency, the calculator helps identify areas where power losses occur. This analysis allows you to focus on minimizing power losses through design adjustments, material selection, and lubrication optimization.

- Visualization of Gear Behavior: Some gear calculators offer visualizations or simulations of gear behavior, allowing you to observe the gear meshing, contact patterns, and load distribution. These visual representations help in understanding how the gears interact and identifying any potential issues such as uneven wear or improper tooth engagement. With this insight, you can make informed design decisions to improve gear performance and efficiency.

- Iterative Design Optimization: Gear calculators facilitate iterative design optimization by allowing you to quickly evaluate the impact of design changes. You can modify gear parameters such as tooth profile, gear dimensions, or material properties and observe the resulting changes in performance metrics. This iterative process helps in fine-tuning the gear design to achieve higher efficiency and better overall performance.

- Comparative Analysis: Gear calculators often allow you to compare multiple design options side by side. This feature enables you to evaluate the performance characteristics of different gear configurations, materials, or tooth profiles. By comparing these options, you can select the most efficient and suitable design for your specific application requirements.

By leveraging the capabilities of a gear calculator, you can optimize gear system performance by fine-tuning gear parameters, improving load distribution, minimizing power losses, and enhancing overall efficiency. The calculator serves as a valuable tool in the design process, enabling you to make data-driven decisions that lead to improved gear performance and more efficient power transmission.