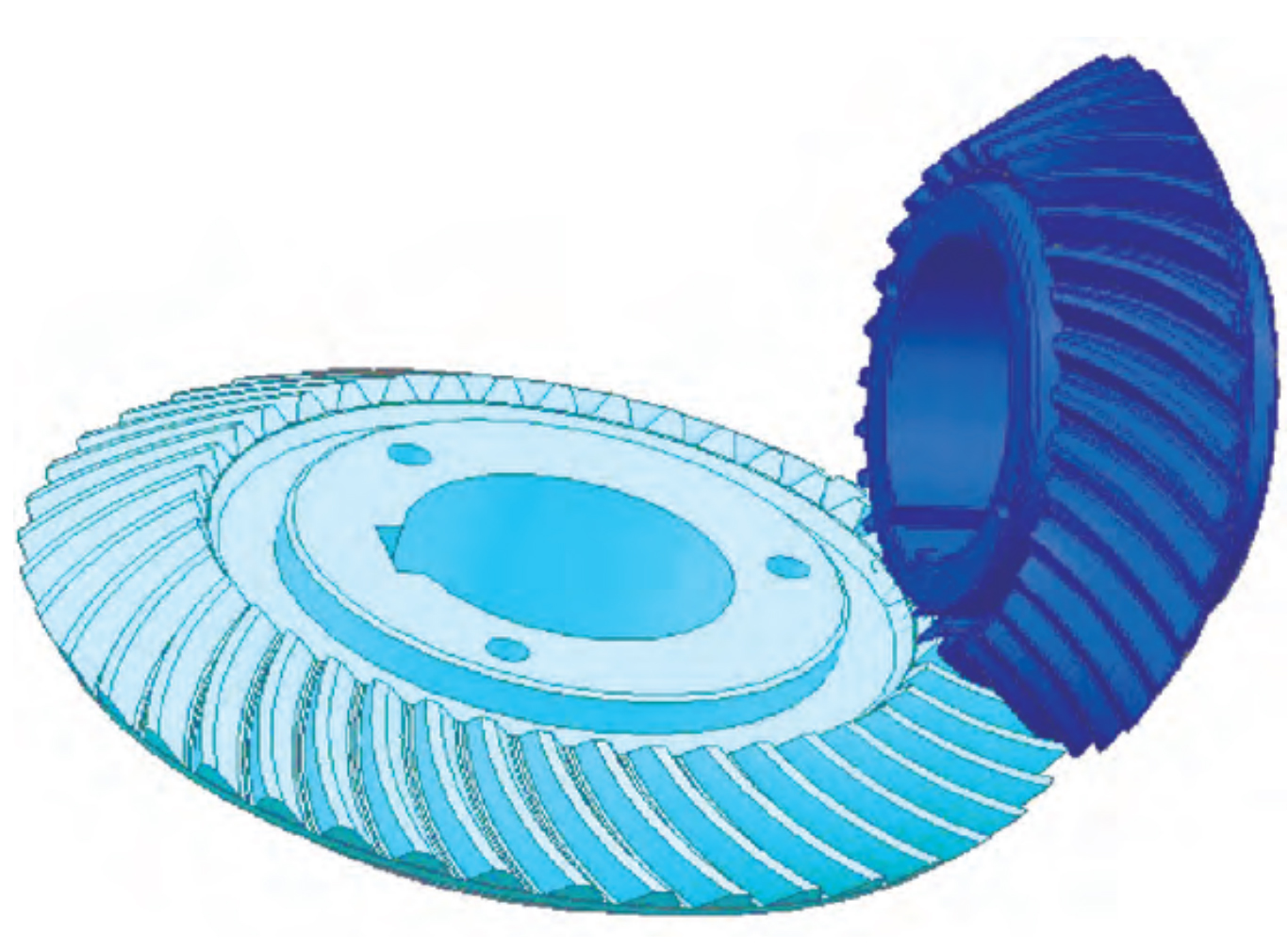

Spiral bevel gears, known for their helical tooth design and efficient operation, are instrumental in the evolution of industrial machinery. They allow for a seamless transfer of power between intersecting axes, delivering smooth and quiet performance in a wide range of applications. This article will explore how spiral bevel gears are transforming industrial machinery, bringing about improvements in efficiency, performance, and longevity.

Improving Efficiency and Reducing Noise:

In industrial machinery, high levels of noise and vibration can lead to a challenging work environment and decreased machine lifespan. The distinctive helical design of spiral bevel gears allows for gradual tooth engagement during operation, leading to quieter operation and reduced vibration. This not only contributes to a more conducive work environment but also minimizes wear and tear on the machine, enhancing its longevity and reducing maintenance requirements.

Boosting Performance and Versatility:

The design of spiral bevel gears allows them to handle higher levels of torque compared to other types of gears. This makes them particularly suitable for heavy-duty industrial machinery that requires robust and reliable components for optimal performance.

Moreover, the versatility of spiral bevel gears enables their use in machinery with varying shaft angles. Whether the requirement is for transmitting power between perpendicular shafts or at another angle, spiral bevel gears can accommodate these needs. This flexibility allows manufacturers to design more compact and efficient machinery, a valuable advantage in industries where space optimization is essential.

Applications in Various Industrial Machines:

- Conveyor Systems: In conveyor systems, spiral bevel gears are used to control the conveyor belt’s speed and direction. This ensures smooth operation and precise control, which is crucial in industries like food processing, manufacturing, and logistics.

- Milling Machines: Spiral bevel gears play a vital role in milling machines, where they enable the precise movement and control necessary for cutting and shaping materials.

- Power Plants: In power plants, spiral bevel gears are used in turbine systems to efficiently transfer power generated by steam, gas, or water to the generator.

- Printing Presses: In the printing industry, spiral bevel gears are used in printing presses to ensure the precise, high-speed operation necessary for large-scale printing tasks.

- Material Handling Equipment: In equipment like forklifts and cranes, spiral bevel gears facilitate the smooth operation and control required for safe and efficient material handling.

Spiral bevel gears are an essential component in the advancement of industrial machinery. By enhancing efficiency, reducing noise, and providing versatile power transmission solutions, they are transforming how industries operate. As technological advancements continue, it is anticipated that the applications and benefits of spiral bevel gears in industrial machinery will continue to expand, further streamlining operations and improving performance in a variety of sectors.