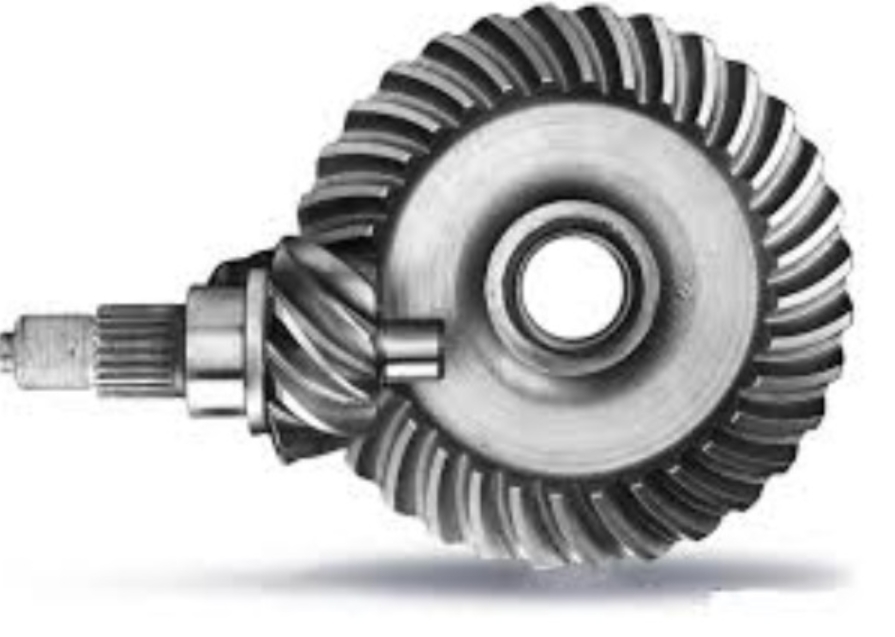

Hypoid gear have indeed been a game changer in automotive design, particularly in terms of performance and efficiency. Their unique characteristics have made them a preferred choice for several critical applications in vehicles. Let’s explore how hypoid gear impact automotive design and performance:

Key Roles of Hypoid Gear in Automotive Design

- Differentials: The most common application of hypoid gear in automobiles is in the differential, which is part of the drive axle. In rear-wheel-drive (RWD) and all-wheel-drive (AWD) vehicles, hypoid gear allow the drive shaft to connect at a lower point to the differential, improving vehicle stability and cabin space.

- Improving Vehicle Dynamics: The lower center of gravity afforded by the hypoid gear configuration contributes to better handling and stability in cars, especially at high speeds or during sharp turns.

- Transmission of Power: Hypoid gear enable the efficient transmission of power from the engine to the wheels, especially at varying angles, which is critical in vehicles with complex drive layouts.

Advantages of Hypoid Gear in Automotive Performance

- Enhanced Load Capacity: Their ability to handle higher loads without increasing the size of the gear system is a significant advantage, particularly for heavy-duty vehicles and SUVs.

- Reduced Noise and Vibration: Hypoid gear operate more quietly and with less vibration compared to traditional gear, contributing to a smoother driving experience.

- Fuel Efficiency: By optimizing the power transfer and reducing mechanical losses, hypoid gear can contribute to better fuel efficiency in vehicles.

- Compact Design: Their design allows for more compact transmission systems, freeing up space for other vehicle design and engineering enhancements.

- Durability: With proper lubrication and maintenance, hypoid gear tend to have a long service life due to their robust construction and the even distribution of loads across the gear teeth.

Challenges in Automotive Applications

- Manufacturing Complexity: The production of hypoid gear requires precise machining and quality control, making them more complex and costly to manufacture than simpler gear types.

- Maintenance and Lubrication: Due to their unique geometry and the high pressures they endure, hypoid gear require high-quality lubricants and regular maintenance to prevent wear and ensure longevity.

- Design Constraints: While offering many benefits, the design of hypoid gear also imposes certain constraints, requiring careful consideration in overall vehicle design, particularly in the drivetrain.

Conclusion

In the realm of automotive design, hypoid gear have been revolutionary, particularly in enhancing vehicle performance, stability, and efficiency. Their application in differentials has been particularly impactful, revolutionizing how power is transmitted in many modern vehicles. As automotive technology continues to evolve, the role of hypoid gear in achieving optimal performance and efficiency remains significant, underscoring their importance in the industry’s ongoing quest for innovation and improvement.