Hypoid gears are machined by generating line cutting method. The basic principle of this method is that the tooth cutting tool is formed by the contact line of the tooth surface, and the motion conditions of the tooth cutting machine tool are provided according to the motion of the meshing surface. Compared with traditional machining methods, the advantages are as follows: 1) cutting hypoid gears only requires three-axis linkage, and the required machine motion is relatively simple. 2) The cutting tools used in the machining process are relatively simple, which can save the cost to the greatest extent.

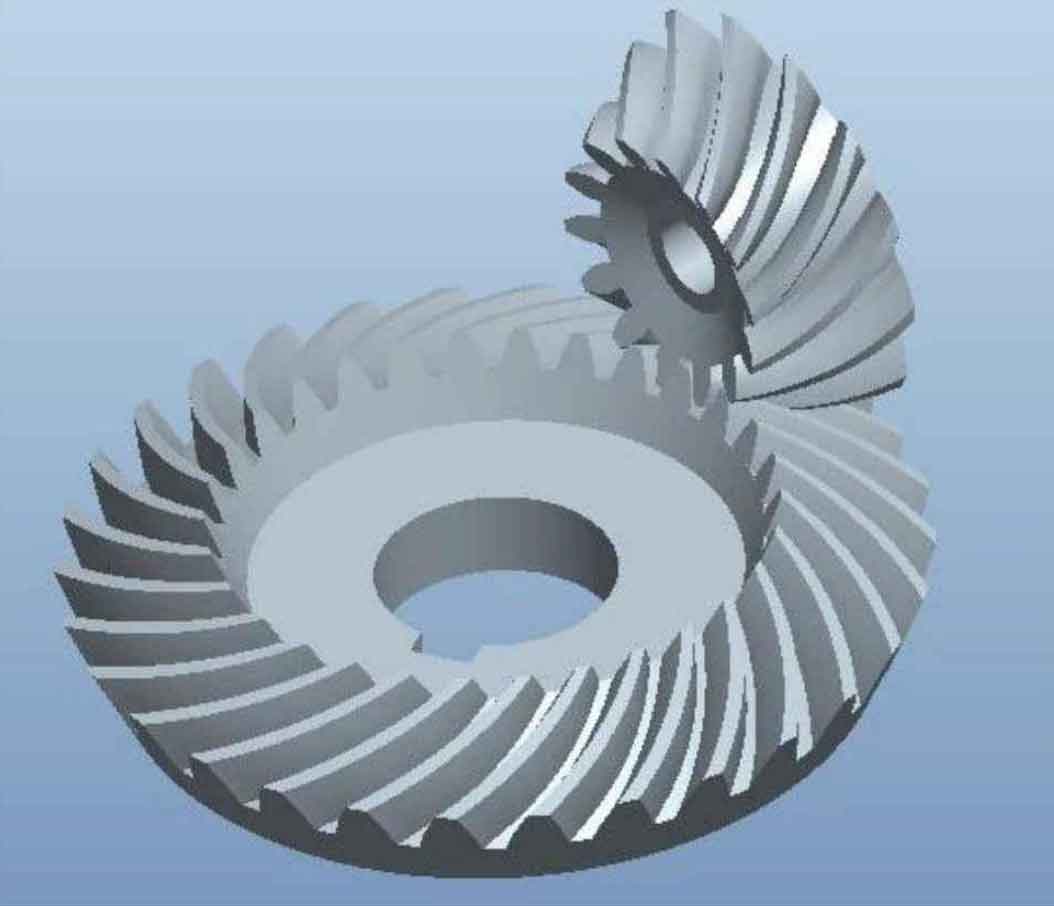

A hypoid gear can be machined into a spherical involute tooth profile, and then the corresponding small gear can be machined according to the meshing principle of the hypoid gear. Finally, the big gear surface and the small gear surface can be conjugate. Therefore, the processing idea adopted is as follows: the large wheel of hypoid gear adopts spherical involute tooth shape. On the basis of ensuring the conjugate meshing principle of gear, the center of the base plane of the small wheel is determined through the cone top relationship of the base plane to further process the small wheel.

The machining of hypoid gear will verify the theory of hypoid gear machining by profile cutting method, and provide a new idea for other types of gear machining.