The automobile has a development history of more than 100 years. With the continuous development and progress of technology, various performances of the automobile have been greatly improved, and the technology is more mature and reliable. As the main part of the transmission system, the rear axle will directly affect the overall quality of the vehicle. Hypoid gear has been developed for more than 60 years. It has been widely used because of its good meshing performance, stable transmission, low noise, high bearing capacity, compact structure, and can reduce the center of gravity of the transmission device.

Especially in the automotive industry, hypoid gears are widely used in the main reducer of automobile drive axle. When the hypoid gears of the main reducer mesh, there will be large vibration and noise. Reducing the vibration and noise of the main reducer is of great significance for improving the comfort of the car. Automobile vibration, noise and comfort are inseparable. The three are related to each other. It is necessary to reduce automobile vibration and noise, improve automobile riding comfort, and ensure product performance and economic benefits. The meshing simulation analysis of hypoid gear transmission can greatly shorten the research and development time and reduce the labor cost. It is of great significance to improve the efficiency of product design and development.

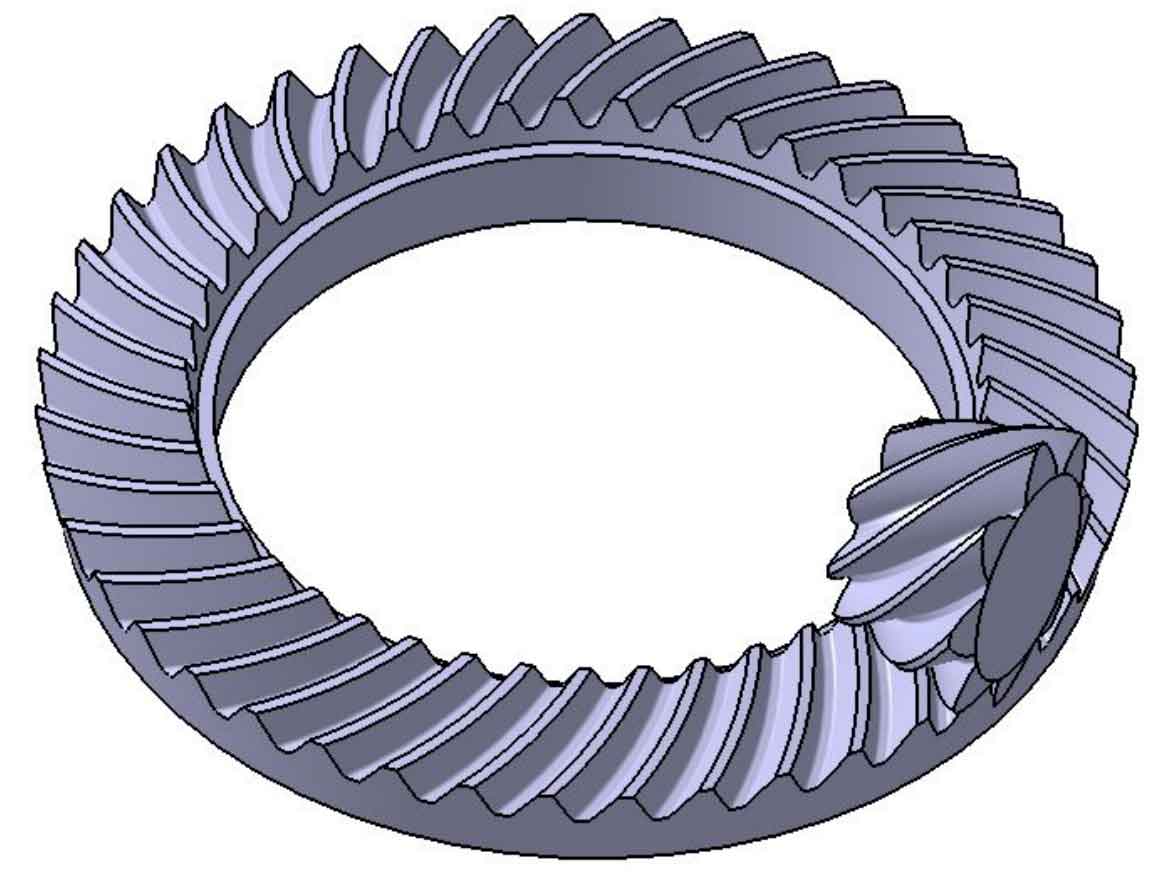

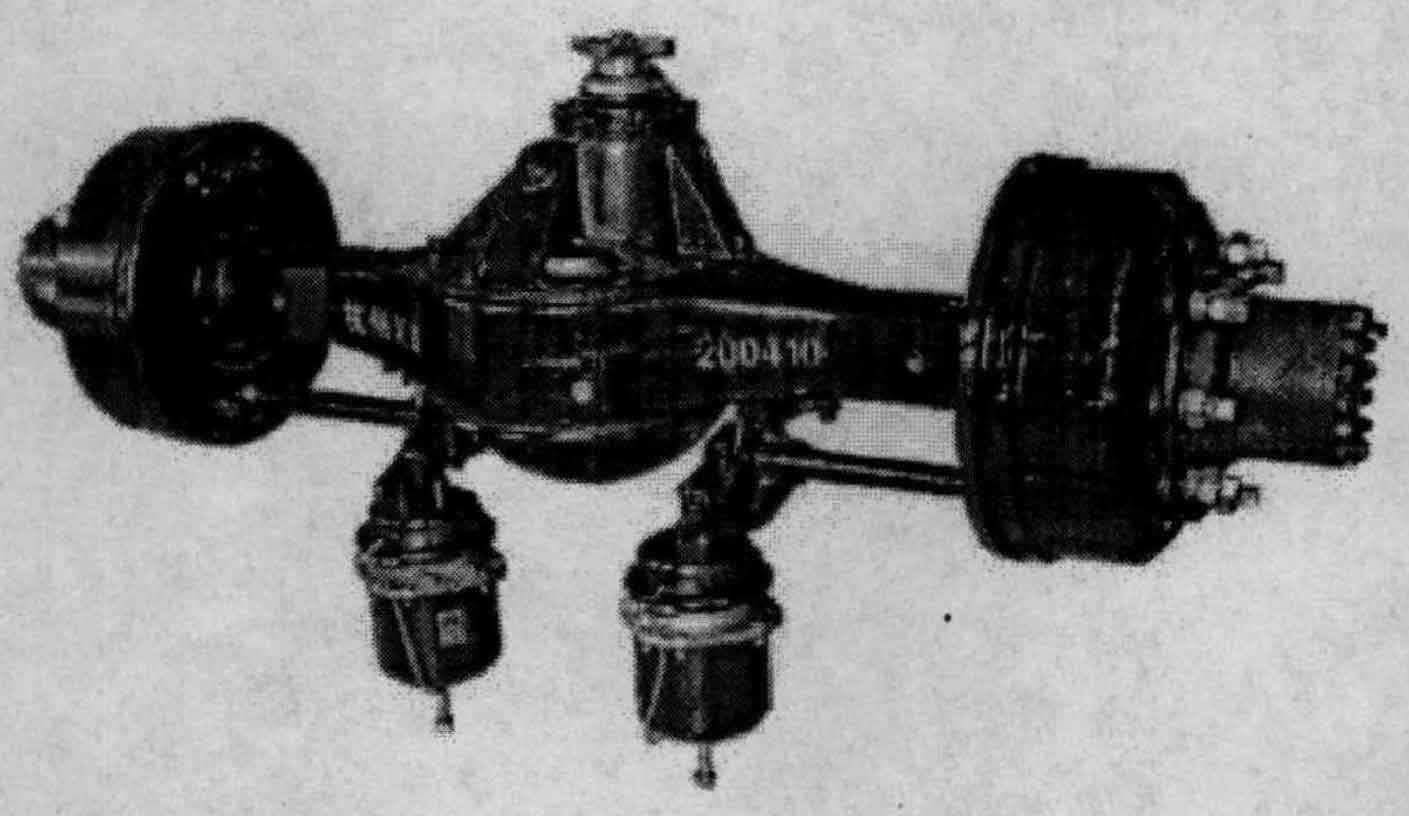

In recent years, with the rapid development of automotive industry technology, people have higher and higher requirements for minicars. Minicars are required not only to meet the requirements of driving and cargo, but also to pay more attention to their ride comfort. As an important part of the main reducer of the rear axle (as shown in the figure), the hypoid gear is mainly used to increase the input torque of the transmission shaft, reduce the speed, and adapt to the change of vehicle speed. The structure of the main reducer assembly has a direct impact on the power performance, economy and portability, transmission stability and efficiency of the minicar.

During the meshing process of the hypoid gear of the main reducer of the rear axle of the micro car, the hypoid gear transmits a large torque, the tooth surface bears a great pressure, and the tooth root receives a large bending moment. The meshing stiffness also changes constantly, causing a great vibration of the hypoid gear transmission system. In addition, tooth profile error, tooth pitch deviation, bearing manufacturing and installation error will also cause vibration of the rear axle. However, all noise comes from vibration, and vibration and noise always accompany the driving process. Excessive vibration will cause the early fatigue damage of the transmission parts and support structure of the vehicle, thus reducing the service life; Excessive noise will affect the hearing of the unwheeling driver, make the driver tired, affect the safe driving of the car, and also affect the riding comfort of the minicar. Therefore, reducing vibration and noise is of great significance for improving the ride comfort of automobiles.