Hypoid gear technology represents a significant advancement in the field of mechanical engineering, primarily due to its unique design and the benefits it offers over traditional gear systems. Here’s a brief overview:

What are Hypoid Gear?

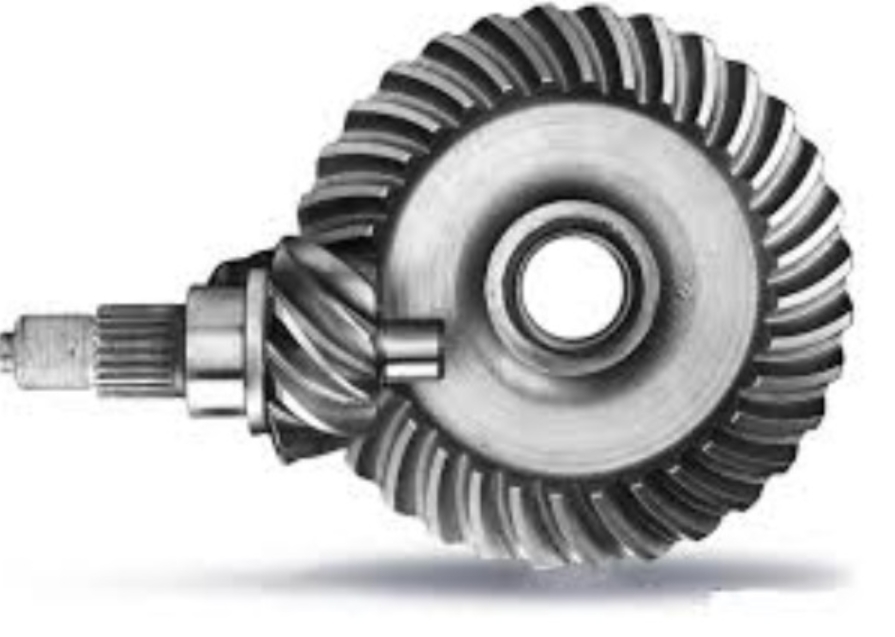

- Design: Hypoid gear is type of bevel gear, but with a slight twist. The axes of hypoid gear do not intersect, unlike standard bevel gear. This offset allows for larger diameter gear and more teeth in contact during operation.

- Contact: They have a more complex geometry which allows for continuous tooth engagement. This leads to smoother operation and less vibration.

Advantages

- Increased Load Capacity: The larger size and increased tooth contact area allow hypoid gear to handle heavier loads compared to traditional gear.

- Reduced Noise and Vibration: Their smooth operation makes them quieter, reducing noise and vibration. This is particularly beneficial in automotive applications, like in rear axles of cars.

- High Efficiency: Despite their complex design, hypoid gear is highly efficient in transferring power.

- Compact Design: The non-intersecting shafts allow for a more compact design, making them suitable for tight spaces where traditional gear might not fit.

Applications

- Automotive Industry: They are commonly used in the drivetrains of cars and trucks, particularly in the differential, where they allow the wheels to rotate at different speeds while turning.

- Heavy Machinery: Their ability to handle heavy loads makes them ideal for heavy machinery and industrial applications.

- Aerospace: The compact and efficient design makes them suitable for various aerospace applications.

Challenges

- Manufacturing Complexity: Producing hypoid gear is more complex and costly due to their intricate design.

- Maintenance and Wear: They might require more specialized maintenance and can be more sensitive to misalignment and wear.

Recent Developments

With advancements in manufacturing technologies like CNC machining and 3D printing, the production of hypoid gear has become more precise and cost-effective. This has led to wider adoption in various fields, pushing forward innovations in mechanical design and efficiency.

In summary, hypoid gear technology, with its unique features and advantages, has significantly impacted mechanical engineering, offering solutions in various applications where efficiency, load capacity, and compact design are crucial. Its growing use in diverse industries highlights its versatility and importance in modern mechanical design.