In recent years, the competition in the automobile manufacturing industry has become increasingly fierce. In order to speed up the development of new products and reduce the development cost, major automobile manufacturers use virtual prototype technology in the product design process to check and optimize the performance of products. Therefore, based on the finite element analysis method, the reliability and time-varying meshing characteristics of the hypoid gear of the main reducer of the drive axle are studied, a more accurate strength performance analysis model of the hypoid gear is established, and the time-varying meshing characteristics of the gear are analyzed, which provides a theoretical basis for the reliability and noise optimization design of the drive axle gear, and has theoretical and engineering significance for improving the overall performance of the drive axle.

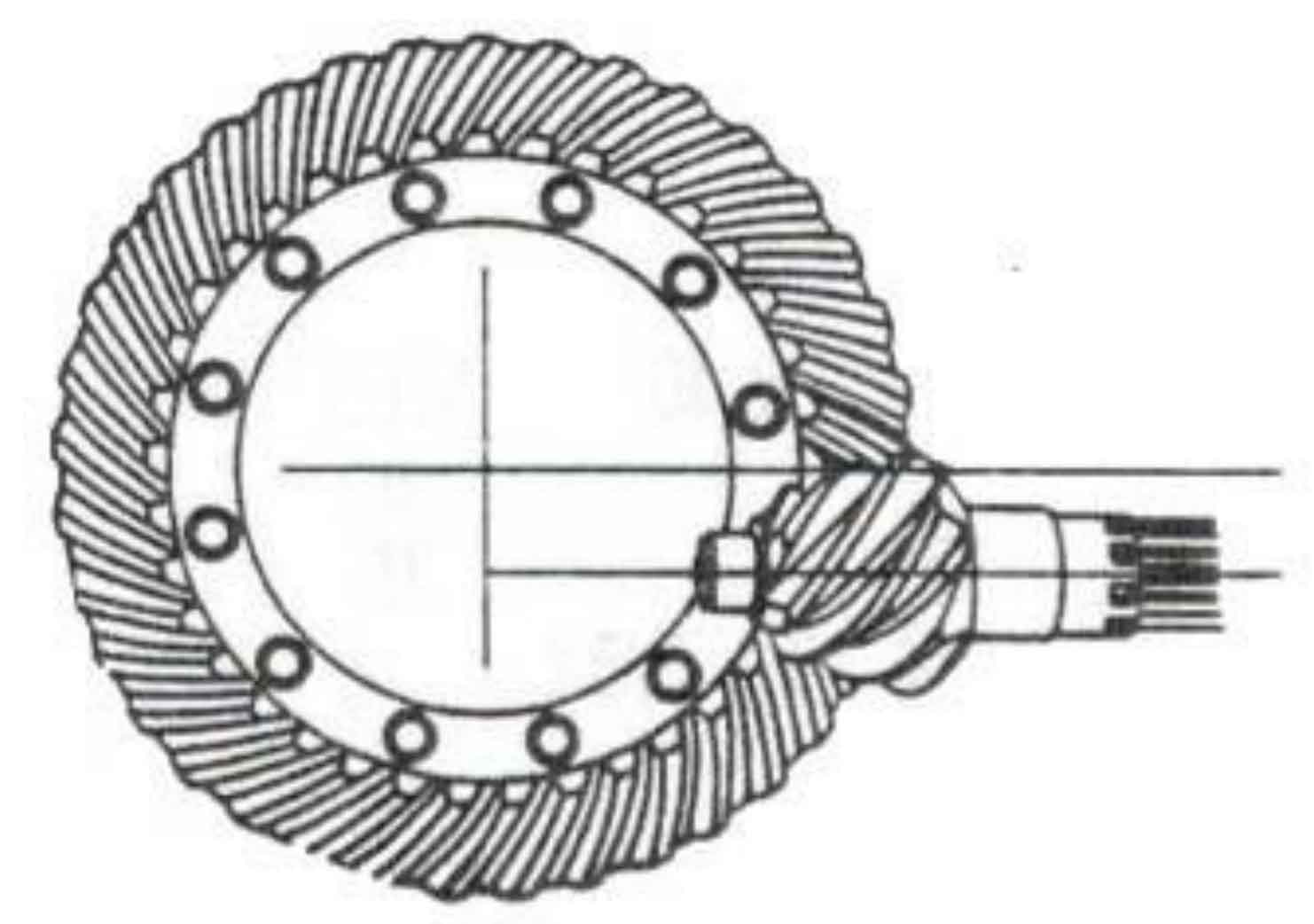

Hypoid gear pair is one of the important moving parts of the drive axle. Its meshing characteristics directly affect the fatigue performance and noise radiation level of the drive axle. In this paper, the geometric modeling method and meshing performance of hypoid gears are studied. Hypoid gear is not only widely used in automobile drive axles such as cars, buses, heavy trucks, but also in power transmission of transmission systems such as aircraft transmissions and engineering machinery. It is one of the most widely used power transmission modes between staggered shafts or non staggered shafts at present. The main difference between hypoid gear and spiral bevel gear: spiral bevel gear has two rotating shafts that are staggered with each other, while hypoid gear has rotating shafts that are not staggered and have a certain offset, as shown in Figures 1 and 2. According to their manufacturing process, hypoid gears can be considered as the general form of this kind of gears. Spiral bevel gears can be derived by limiting the special degrees of freedom in the manufacturing process of hypoid gears. Therefore, many researches on spiral bevel gears can be applied to hypoid gears. Spiral bevel gear has different names in different application fields, such as spiral bevel gear, spiral bevel gear, spiral bevel gear, circular arc bevel gear, spiral bevel gear, etc.

Many scholars have made outstanding contributions to the development of hypoid gear or spiral bevel gear technology. In 1882, French scholar Olivier established the principle of conjugate geometry and defined the conjugate surface as the envelope of the surface family. In 1886, gochman redefined the conjugate surface by using the method of differential geometry and applied it to the theoretical research of gears. Dudley wrote the first edition of gear manual in 1954, and it is widely used in gear production practice. Dr.litvin and other famous gear researchers and research institutions have made outstanding contributions to the development of modern gear theory, and their research results have become an important theoretical basis for gear design and manufacturing.